VC/g-C3N4 photocatalyst preparation method

A photocatalyst, g-c3n4 technology, applied in the field of photocatalysis, can solve the problems of photocatalytic performance degradation and achieve the effect of improving hydrogen production efficiency, low production cost and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) First, mix the mixture according to the mass ratio of dicyandiamide: ammonium bicarbonate: ammonium metavanadate=1:3:2;

[0029] 2) Grind the mixture for 60 minutes, pass through a 60-mesh sieve, put it into a porcelain boat, and heat it up from room temperature to 600°C for 3 hours in a tube furnace at a heating rate of 2°C / min;

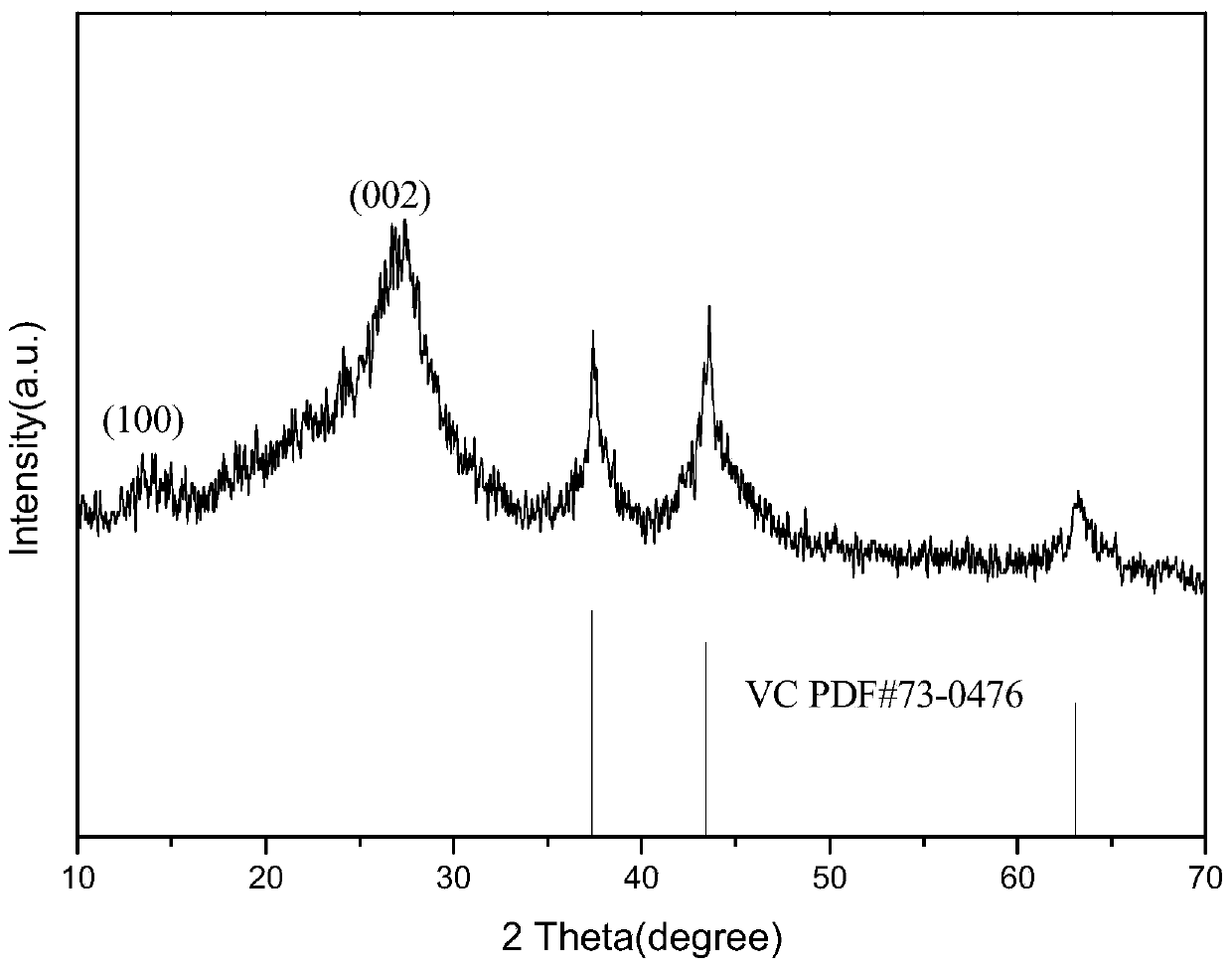

[0030] 3) after calcination, cool naturally with the furnace, first ball mill at a speed of 200rpm for 5 hours, and then ball mill at a speed of 500rpm for 4 hours to obtain VC powder;

[0031] 4) According to the mass ratio of VC powder: citric acid: glucose: dicyandiamide=1:3:2:5, the mixture is obtained;

[0032] 5) Grind the above-mentioned mixture for 100 minutes, pass through a 60-mesh sieve, put it into a porcelain boat, and heat it up from room temperature to 450°C for 2 hours in a tube furnace at a heating rate of 2°C / min;

[0033] 6) After calcination, cool naturally with the furnace and ball mill for 4 hours at a speed of 400rp...

Embodiment 2

[0038] 1) First, mix the mixture according to the mass ratio of dicyandiamide: ammonium bicarbonate: ammonium metavanadate=1:4:3;

[0039] 2) Grind the mixture for 70 minutes, pass through a 50-mesh sieve, put it into a porcelain boat, and heat it up from room temperature to 500°C for 2 hours in a tube furnace at a heating rate of 2°C / min;

[0040] 3) after calcination, cool naturally with the furnace, first ball mill at a speed of 200rpm for 5 hours, and then ball mill at a speed of 500rpm for 4 hours to obtain VC powder;

[0041] 4) According to the mass ratio of VC powder: citric acid: glucose: dicyandiamide = 1:2:2:3, the mixture is obtained;

[0042] 5) Grind the above-mentioned mixture for 70 minutes, pass through a 50-mesh sieve, put it into a porcelain boat, and heat it up from room temperature to 500°C for 3 hours in a tube furnace at a heating rate of 5°C / min;

[0043] 6) After calcination, cool naturally with the furnace and then ball mill for 6 hours at a speed of...

Embodiment 3

[0045] 1) First, mix the mixture according to the mass ratio of dicyandiamide: ammonium bicarbonate: ammonium metavanadate=1:3:5;

[0046] 2) Grind the mixture for 65 minutes, pass through a 40-mesh sieve, put it into a porcelain boat, and heat it up from room temperature to 800°C for 2 hours in a tube furnace at a heating rate of 5°C / min;

[0047] 3) after calcination, cool naturally with the furnace, first ball mill at a speed of 300 rpm for 4 hours, and then ball mill at a speed of 600 rpm for 4 hours to obtain VC powder;

[0048] 4) According to the mass ratio of VC powder: citric acid: glucose: dicyandiamide=2:2:4:6, the mixture is obtained;

[0049] 5) Grind the above mixture for 90 minutes, pass through a 40-mesh sieve, put it into a porcelain boat, and heat it up from room temperature to 600°C for 4 hours in a tube furnace at a heating rate of 10°C / min;

[0050] 6) After calcination, cool naturally with the furnace and ball mill for 4 hours at a speed of 600rpm to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com