Projection glass screen

A projection glass and screen technology, applied in optics, instruments, projection devices, etc., can solve problems such as visual fatigue and poor customer experience, and achieve the effect of reducing intensity, protecting eyes, and reducing glare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

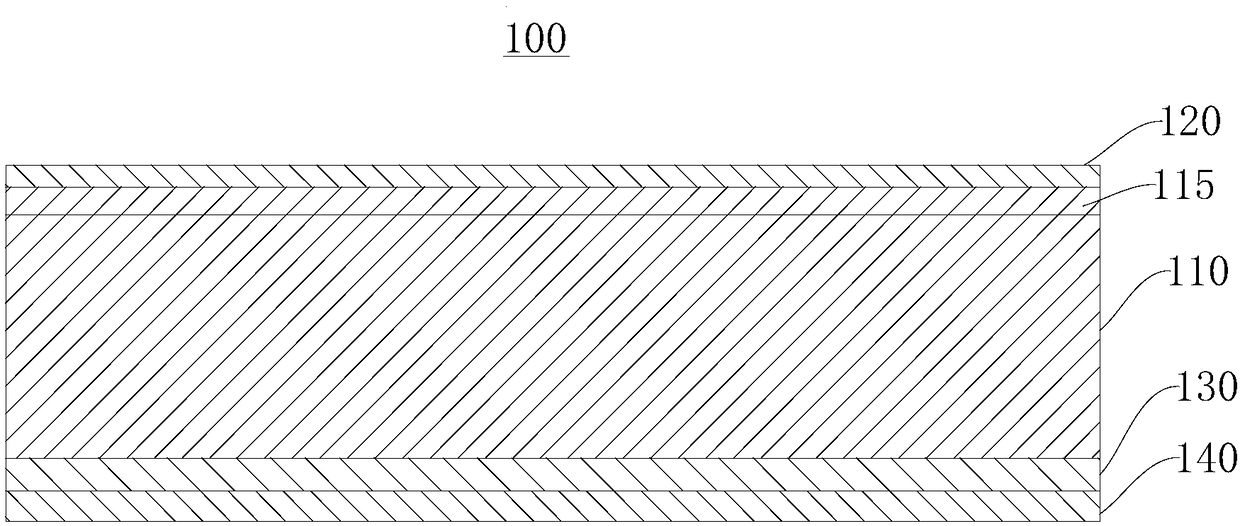

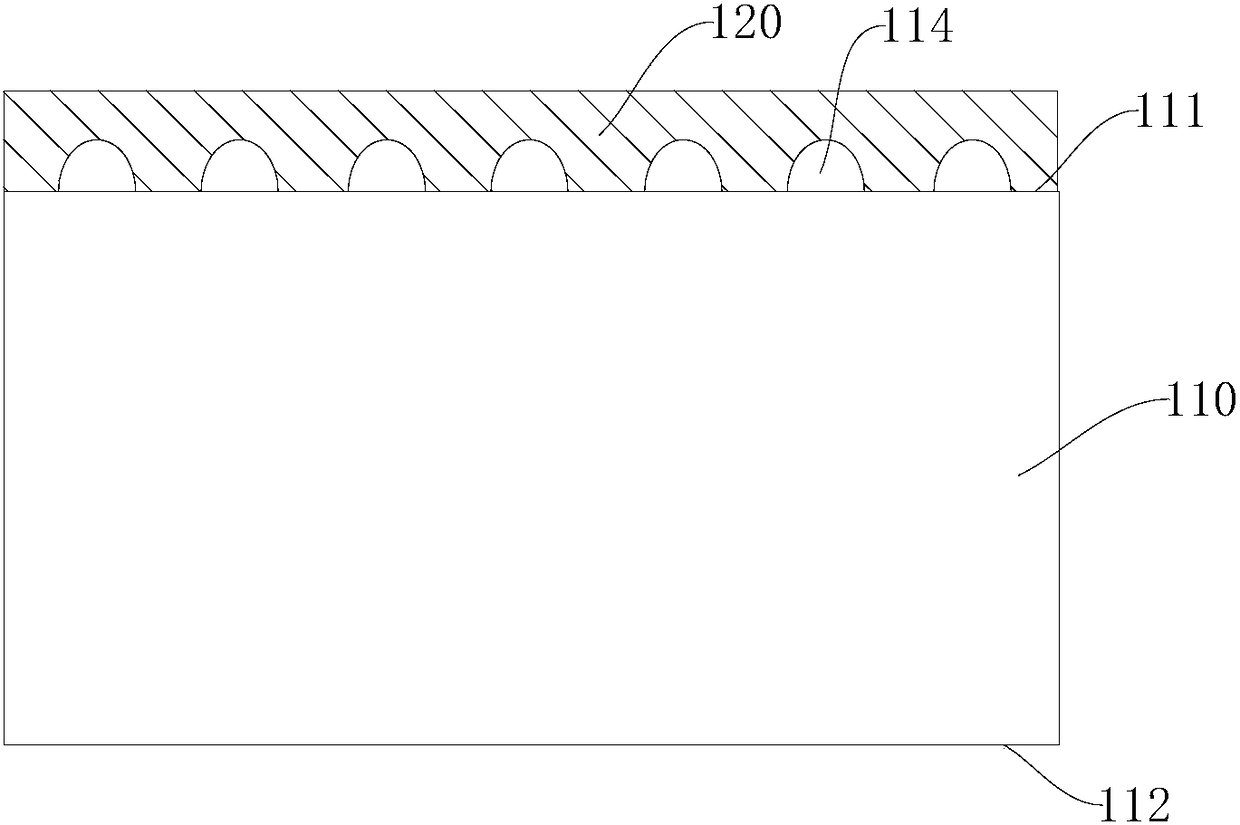

[0032] The preparation process of the projection glass screen 100 includes:

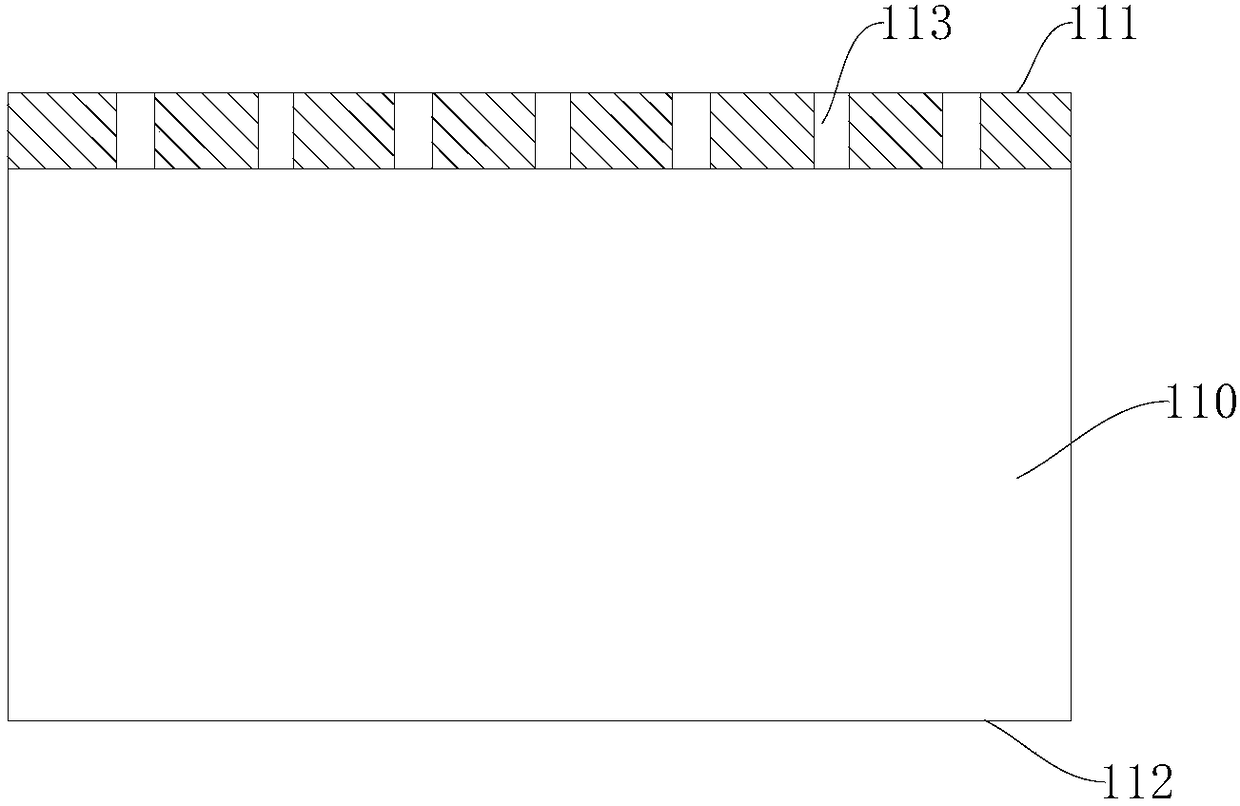

[0033] Step S1: After roughening the first surface of the transparent glass substrate, spraying a nanometer self-cleaning coating with photocatalysis;

[0034] Preferably, the light transmittance of the transparent glass substrate is greater than 85%, preferably greater than 90%.

[0035] More preferably, after the first surface is roughened, the roughness is 0.05-1.5 μm, or 0.1-1.3 μm, or 0.3-1.1 μm, or 0.5-1.0 μm, or 0.7-0.9 μm.

[0036] Further, the rough surface treatment is an etching method, and the depth of the groove after etching is 0.3-0.8 μm, or 0.4-0.7 μm, or 0.5-0.6 μm; the width of the groove is 130-160 μm, or 135-155 μm , or 140-150 μm, or 143-147 μm.

[0037] Further, it also includes: tempering the transparent glass substrate treated by the etching method, so as to enhance the hardness of the transparent glass substrate and improve the safety of use.

[0038] Alternatively, the ro...

Embodiment 1

[0070] The present embodiment provides a spectral light-absorbing coating, which includes by weight parts:

[0071] 90 parts of metal color paste, 30 parts of synthetic resin, 6 parts of additives.

[0072] Wherein, metal color paste comprises by weight parts:

[0073] 65 parts of silver metallic pigment, 13 parts of yellow metallic pigment, 4 parts of red metallic pigment, 3 parts of blue metallic pigment, 5 parts of green metallic pigment.

[0074] The preparation method of this spectral light-absorbing coating is:

[0075] a. Grinding the resin-wrapped silver flakes into fine powders to obtain silver metallic pigments.

[0076] b. Attach the yellow light-color film, red light-color film, blue light-color film and green light-color film to the surface of the metal silver sheet respectively. The ratio of the thickness of the metal silver sheet to the light-color film is 30:1, tear off After filming, grind into powder to obtain yellow metallic pigment, red metallic pigment,...

Embodiment 2

[0080] The present embodiment provides a spectral light-absorbing coating, which includes by weight parts:

[0081] 45 parts of metal color paste, 50 parts of synthetic resin, 3 parts of additives.

[0082] Wherein, metal color paste comprises by weight parts:

[0083] 35 parts of silver metallic pigment, 3 parts of yellow metallic pigment, 2 parts of red metallic pigment, 3 parts of blue metallic pigment, 2 parts of green metallic pigment.

[0084] The preparation method of this spectral light-absorbing coating is:

[0085] a. Grinding the resin-wrapped silver flakes into fine powders to obtain silver metallic pigments.

[0086] b. Attach the yellow light-color film, red light-color film, blue light-color film and green light-color film to the surface of the metal silver sheet respectively. The thickness ratio of the metal silver sheet to the light-color film is 10:1, tear off After filming, grind into powder to obtain yellow metallic pigment, red metallic pigment, blue me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com