Impact jet array phase change cooling device combined with foam metal

A foam metal, impinging jet technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problem of liquid phase working medium replenishment and limited effect, and achieve the effect of being conducive to independence, good separation, and improving CHF.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

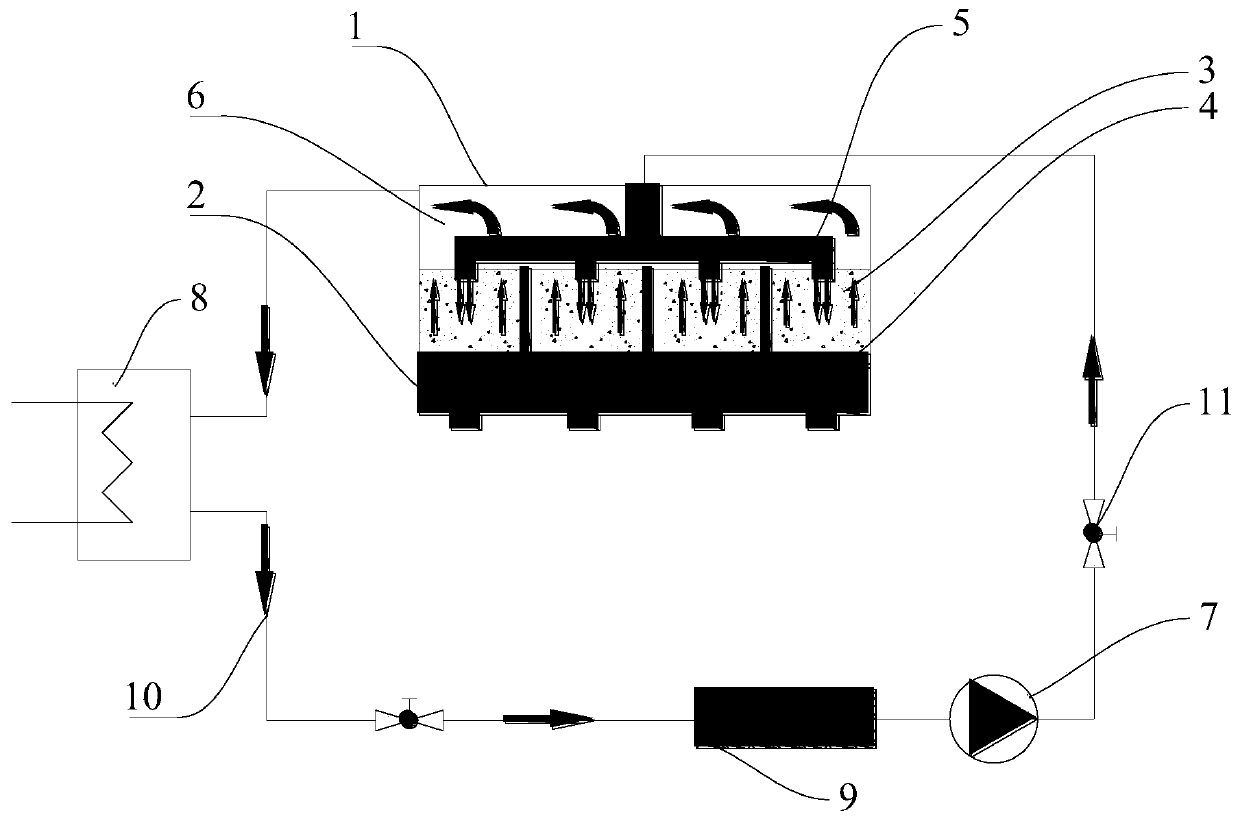

[0018] Such as figure 1 As shown, an impingement jet array phase-change cooling device combined with metal foam includes a heat sink chamber (1), a substrate (2), a working chamber (3), a metal foam capillary core (4), a flow divider (5 ), steam chamber (6), pressure pump (7), condenser (8), dry filter (9) and working medium (10). The heat sink chamber 1, the pressure pump 7, the filter (9) and the dry condenser 8 are sequentially connected through pipes and valves (11) to form a closed system, wherein the liquid outlet of the pressure pump (7) and the inlet of the heat sink chamber 1 Connect, the liquid inlet of condenser (8) is connected with the outlet of heat sink chamber 1.

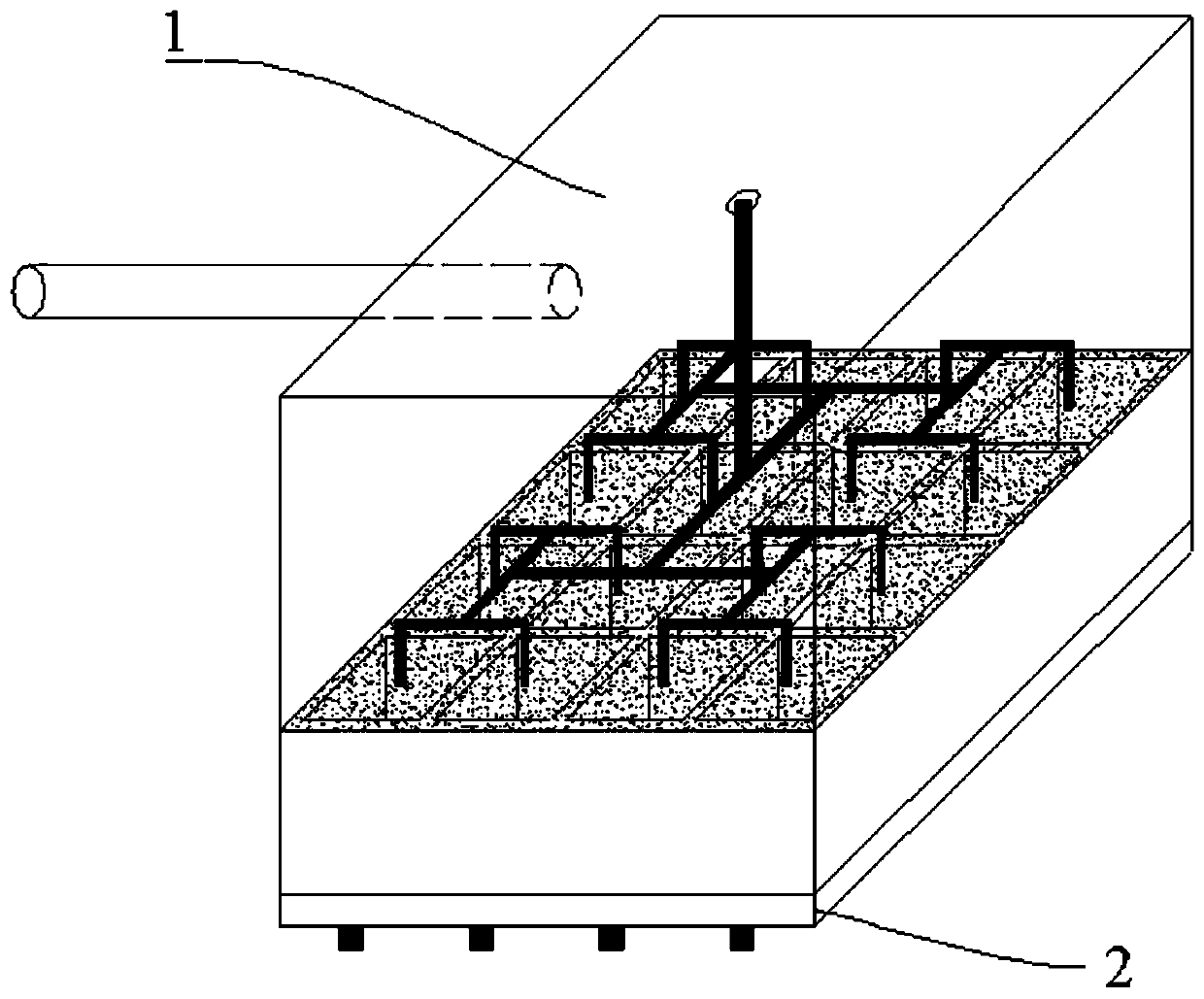

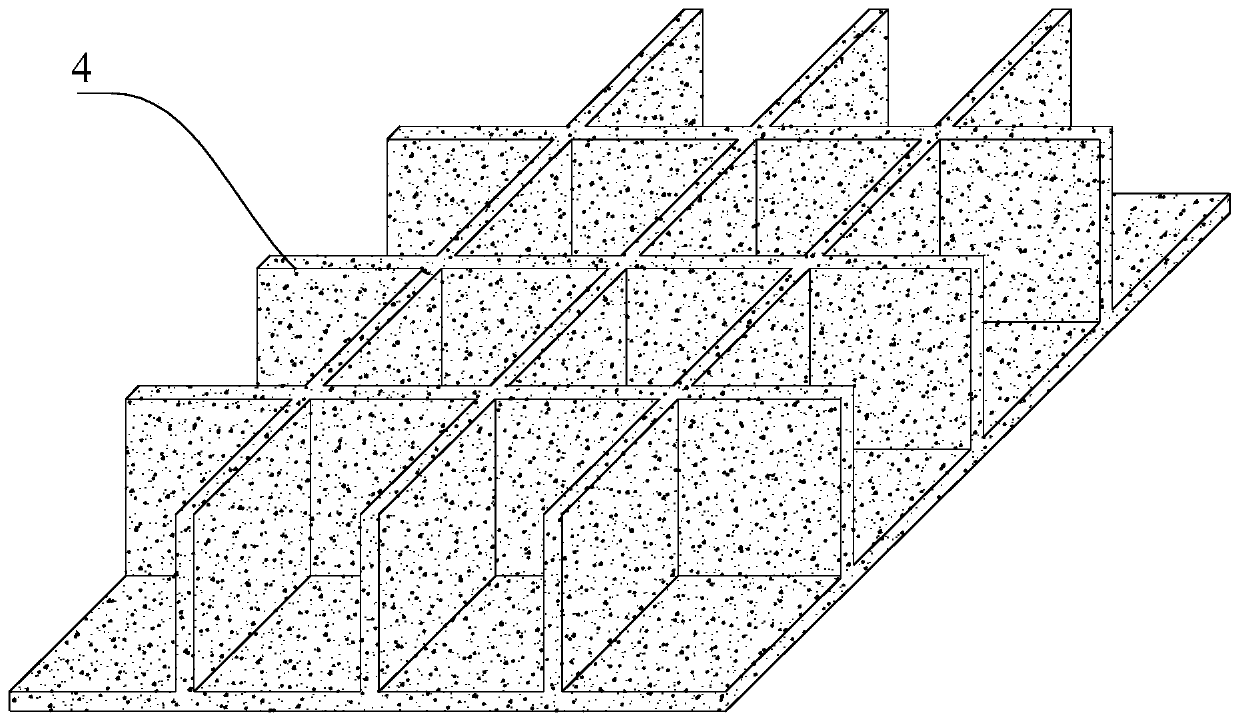

[0019] Such as figure 1 and figure 2 As shown, the shell of the heat sink chamber (1) is made of copper or aluminum alloy, and the heat sink chamber (1) is arranged on the substrate (2) with a heat source and welded with the substrate 2. Before the welding is completed, the metal foam capillary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com