EHD intensification minitype heat radiating device

A heat sink and micro technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating renovation, etc., can solve the problems of high cost and complex system, reduce flow resistance and increase capillary driving force , Improve the effect of capillary driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Attached below Figure 1~5 The present invention is further described.

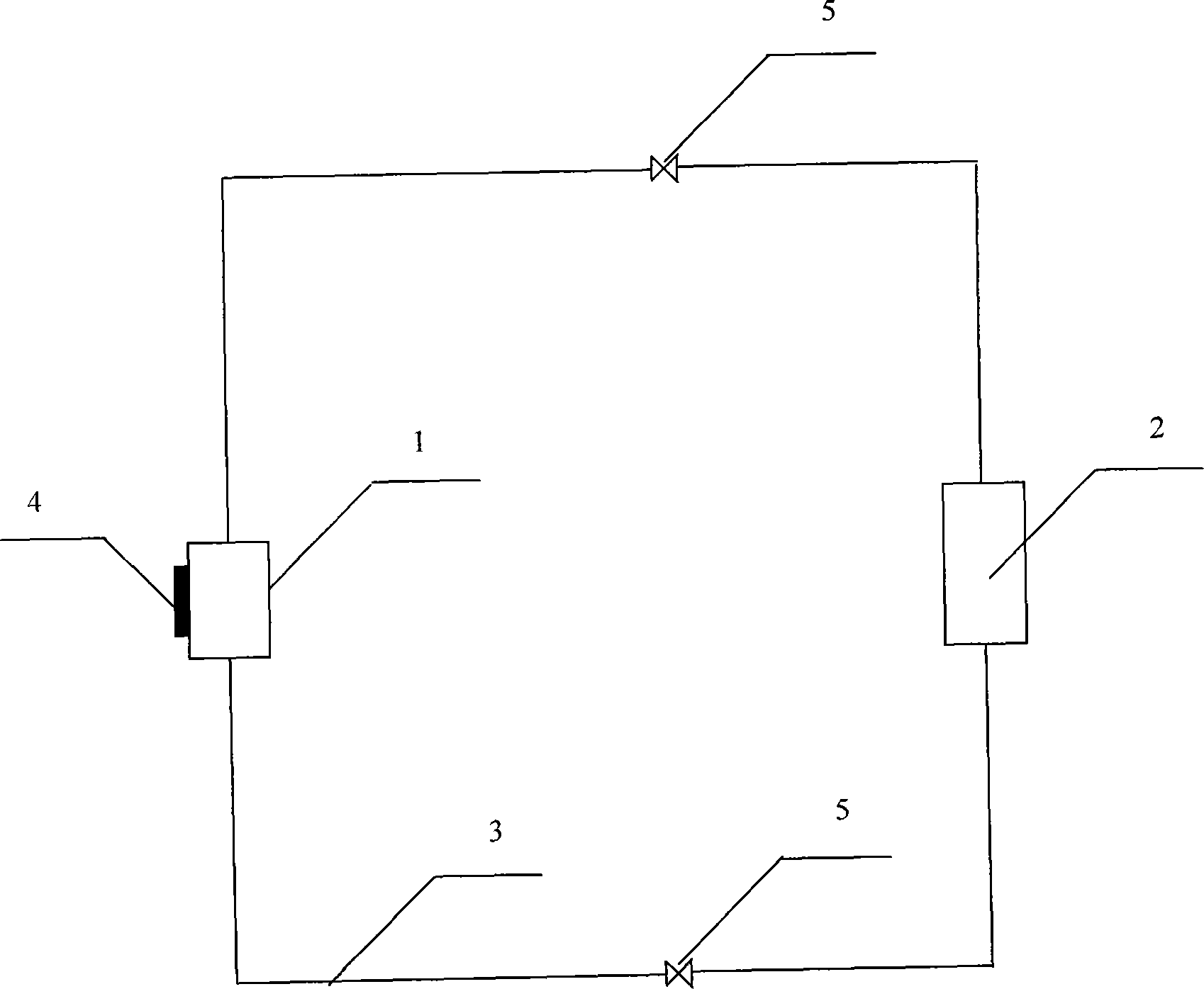

[0024] Such as figure 1 As shown, this embodiment includes an evaporator 1, a condenser 2, a soft plastic capillary 3, a high voltage generating device and electrodes. The components in this embodiment are composed of soft plastic capillary tubes 3 in series in the order of condenser 2 and capillary evaporator 1 (with high-voltage electrodes 9 inside) to form a one-way circulation loop.

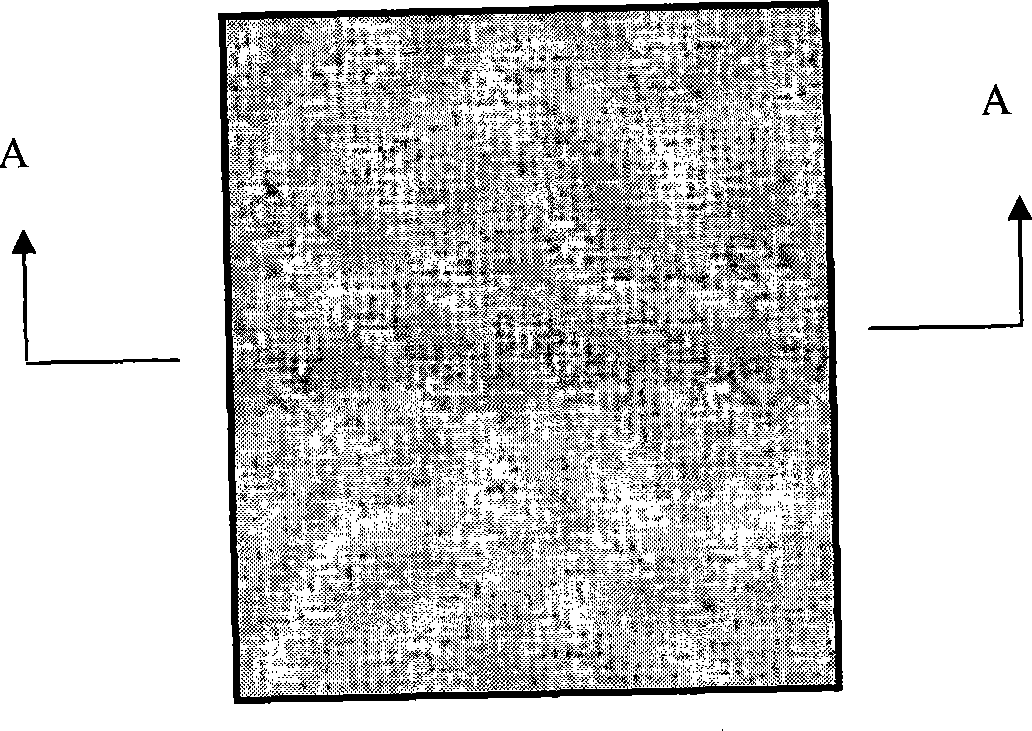

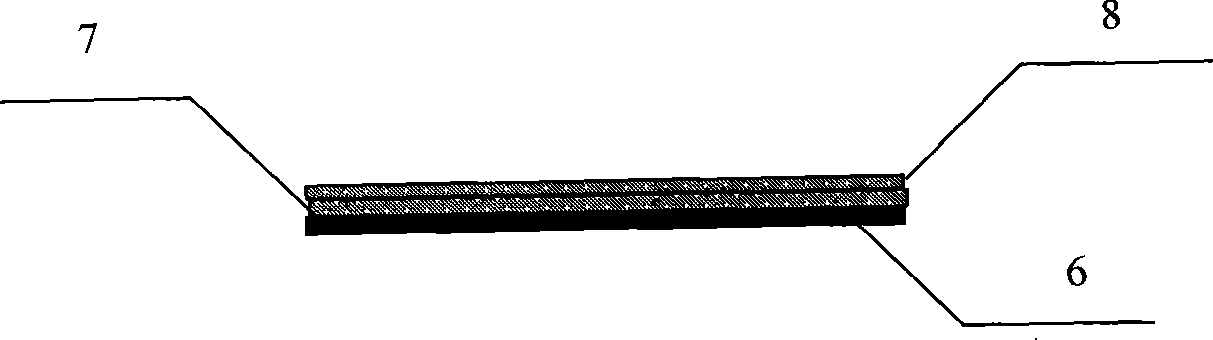

[0025] The layout of the capillary wick evaporator is shown in Figure 2. The capillary wick in the evaporator 1 is a combined capillary core fixed on the substrate 6, and the combined capillary core includes an inner layer of wire mesh and an outer layer of wire mesh, as shown in Figure 2(b ) shown. The pore size of the inner screen 7 is greater than 15 μm, and the pore size of the outer screen 8 is in the range of 5 μm˜10 μm. In this way, when the evaporator is working, the pore diameter of the inner capillar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com