Surface evaporation air cooler heat transfer pipe bundle having membrane expanding plate

A technology of evaporative air cooling and heat exchange tube bundles, which is applied in indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., and can solve problems such as the need to improve the efficiency of evaporation heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

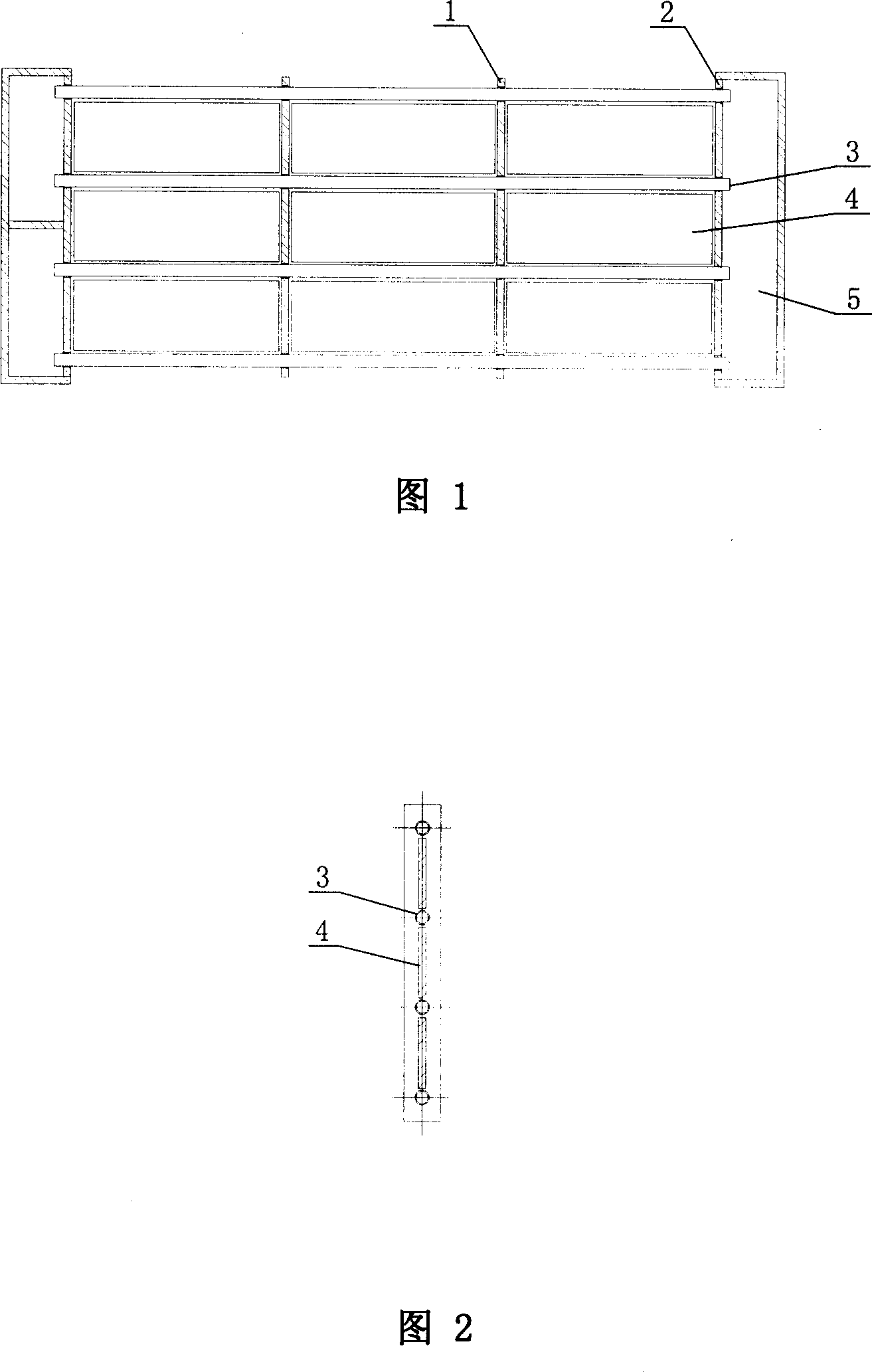

[0012] Figure 1 shows the position of the film-added plate in the heat exchange tube bundle. The tube box 5 is fixedly connected with the tube plate 2; the heat exchange light tube 3 communicates with the tube box 5; the heat exchange light tube 3 is fixed on the tube plate 2 (the fixing method is not shown in the figure, which is conventional); the heat exchange light tube Longer, in order to prevent it from deflecting under the action of gravity, a support plate 1 is added in the middle; the light heat exchange tube passes through the tube hole on the support plate.

[0013] The film-added plate 4 is directly below the upper heat exchange light pipe and directly above the lower heat exchange light pipe. There is a reasonable gap between the film-added plate and the upper and lower heat exchange light tubes, so as not to affect the tube penetration operation d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com