Heated part for multi-angle detection of boiling heat transfer, and experimental device and experimental method thereof

A technology of boiling heat exchange and experimental device, applied in the field of phase change heat, can solve the problems of inability to detect the experimental performance of the modified surface with different placement angles, and achieve the effects of ensuring sealing, convenient operation and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

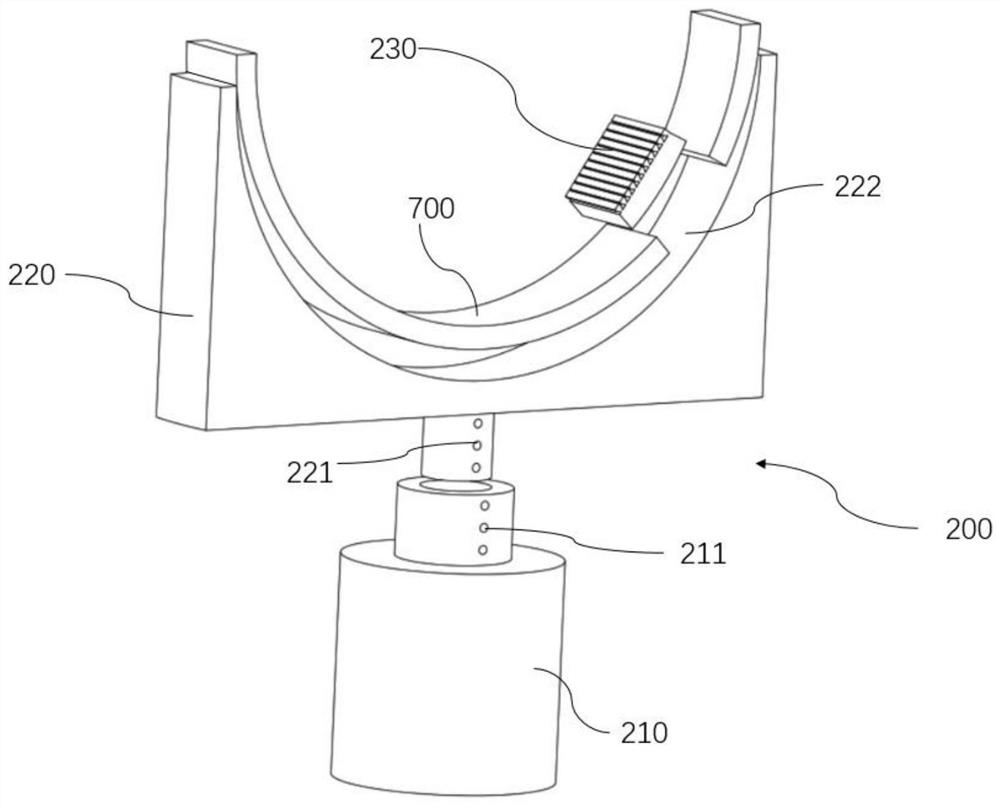

[0056] figure 1 A structural schematic diagram of a heating element for multi-angle detection of boiling heat exchange proposed by the present invention is shown. For the convenience of description, the "up", "down", "left" and "right" referred to below are consistent with the up, down, left and right directions of the drawings themselves, but do not limit the structure of the present invention.

[0057] Such asfigure 1 As shown, a heating element for multi-angle detection of boiling heat transfer includes a modified surface part 230 to be tested and a heated column 200 to be tested. The modified surface part 230 to be tested is arranged on the top of the heated column 200 to be tested, and The modified surface part 230 is installed on the heated column 200 to be tested at a variable angle.

[0058] In the embodiment of the present invention, by installing the modified surface part 230 to be measured on the heated part in a variable angle manner, the modified surface part 230...

Embodiment 2

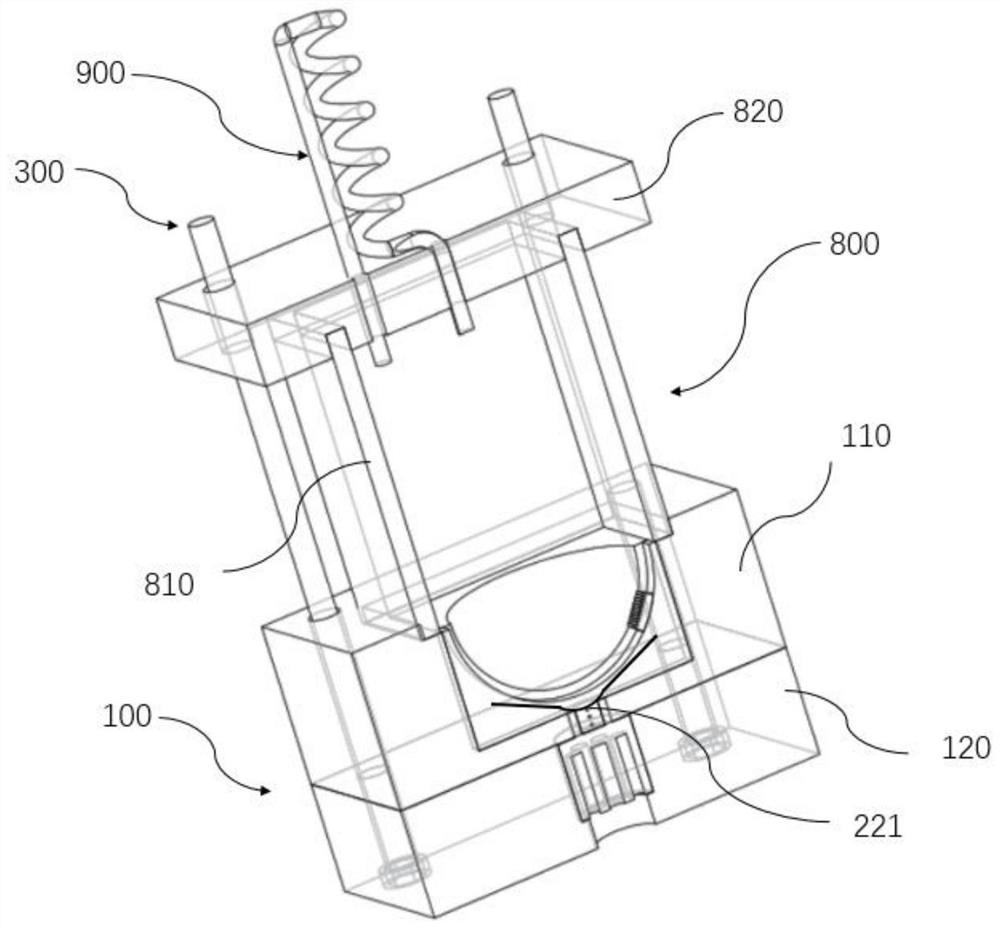

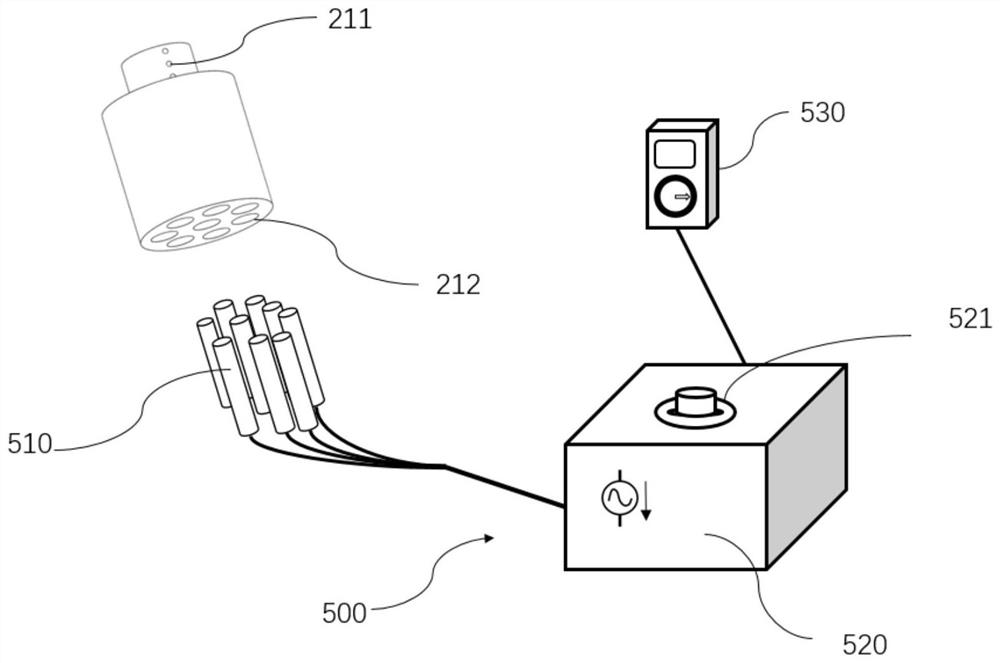

[0063] Such as Figure 2-Figure 5 As shown, the present invention also provides a multi-angle detection boiling heat transfer experimental device, including the heating element, the boiling pool and the heating system 500 for the column to be tested in the above technical solution. Wherein, the boiling pool has a boiling chamber for accommodating liquid working medium and providing a closed space; the heating system 500 for the column to be tested is used for heating the heated column 200 to be tested. The heating system 500 for the column to be tested includes a heating rod 510, a multimeter 530 and an adjustable output power supply 520. Adjust the knob 521 on the output adjustable power supply 520 to change the output power of the output adjustable power supply 520 .

[0064] Such as figure 2 and image 3 As shown, the boiling pool is provided with a tank structure that matches the heated column 200 to be tested. When the heated column 200 to be tested is installed, the ...

Embodiment 3

[0074] In large vessel pool boiling, the surface physical properties and roughness of the heating surface and the vaporization core are the main factors affecting the boiling process. Different rough surfaces have different vaporization core numbers, and the vaporization core affects the growth time and detachment of bubbles. frequency. Through the split design of this embodiment, it is possible to study the bubble growth process of different modified surfaces under different working conditions at different angles, collect multiple experimental data, and provide a basis for further theoretical research.

[0075] The embodiment of the present invention also provides an experimental method for multi-angle detection of boiling heat transfer, using the experimental device for multi-angle detection of boiling heat transfer in any of the above technical solutions to conduct experiments, specifically including the following steps:

[0076] S1: before the experiment, the part of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com