Method for improving surface pool boiling heat transfer performance based on femtosecond laser joint processing technology

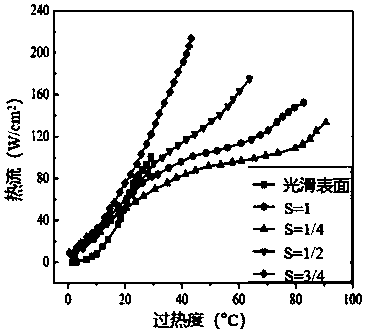

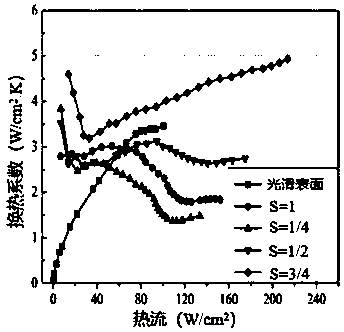

A processing technology, femtosecond laser technology, is applied in the field of enhanced heat transfer, which can solve the problems of performance improvement, limit the practical application of improved surfaces, improve the heat transfer performance of non-heat transfer surfaces, and reduce the surface heat transfer coefficient, so as to achieve low overall cost, Excellent boiling heat transfer performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

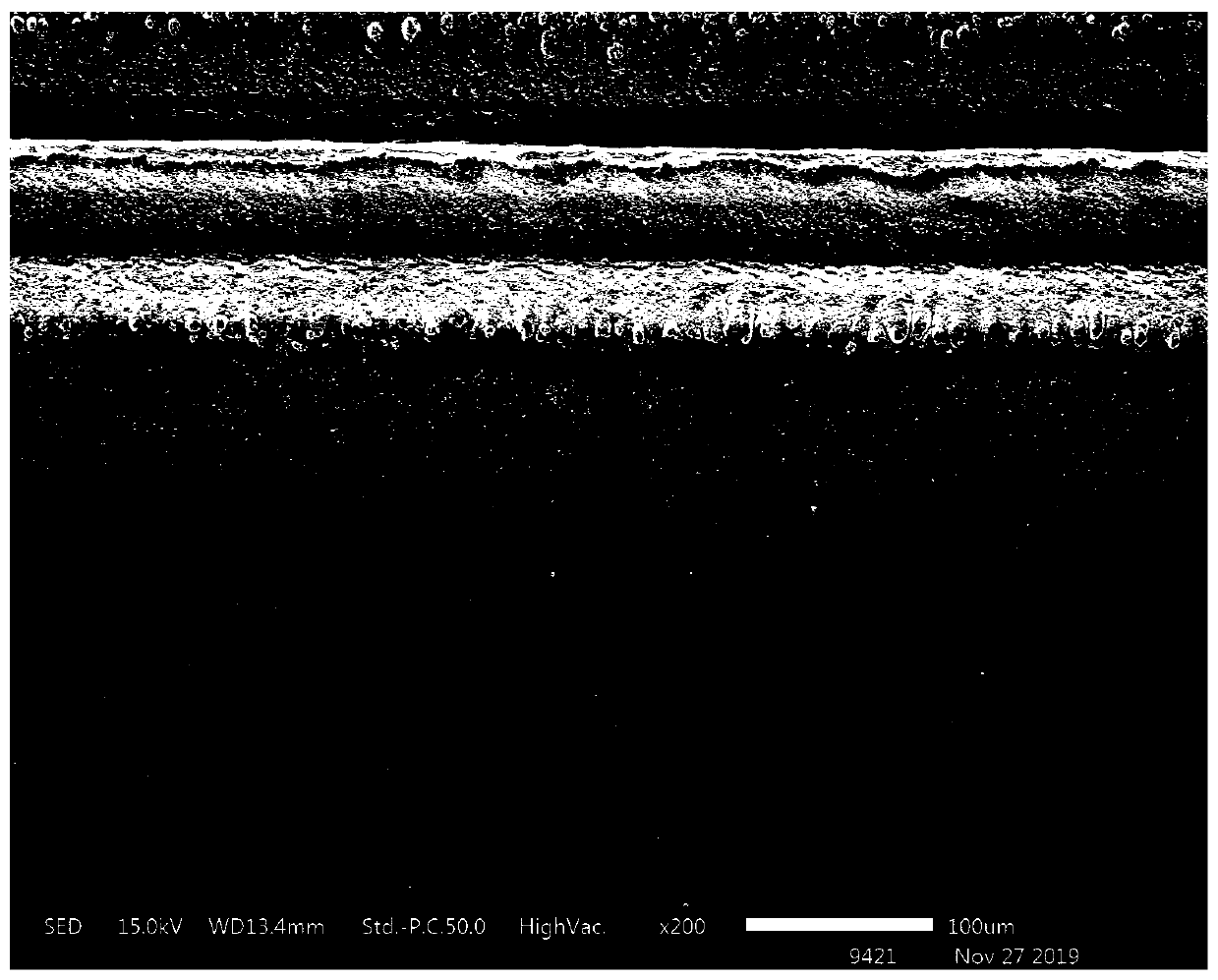

[0024] detailed description:. First of all, choose German Warrior brand sandpaper 400, 600, 800, 1200, 1500, 2000 mesh sandpaper to polish the rough metal surface in a water bath, then use a grinder to polish, and finally use alcohol and deionized water to perform ultrasonic cleaning, and finally obtain the metal surface. Surface roughness (ratio of real area to projected area) is approximately 1, with an average roughness of 0.1 μm.

[0025] The surface is scanned and processed by femtosecond laser raster scanning processing method: the femtosecond laser pulse with a repetition rate of 1kHZ (center wavelength 800nm, femtosecond laser system of Coherent Corporation of the United States) passes through the He-Ne laser collimation system, and then the beam is incident Through the 20cm focusing lens, the femtosecond laser beam focused by the lens is directly on the metal sample on the two-dimensional electric translation stage (the experiment uses a German PI translation stage, X...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com