Liquid-evaporation-type heat radiator and manufacturing method thereof

A technology of liquid evaporation and production method, which is applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., and can solve the problems of difficult heat transfer medium to play a role, difficult heat dissipation of radiator, poor heat dissipation effect of radiator, etc. , to achieve the effect of light weight, small mass and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

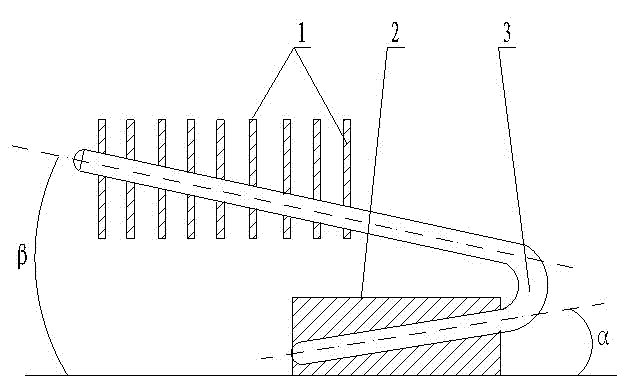

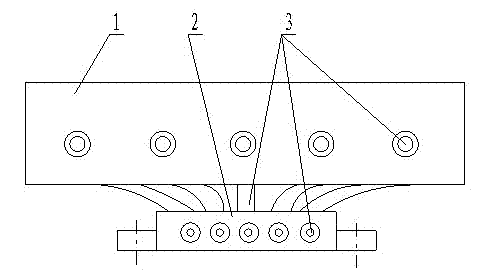

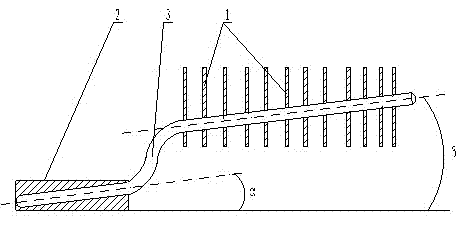

[0020] Embodiment of the present invention: when adopting the manufacturing method of a kind of liquid evaporative heat sink of the present invention to carry out manufacture, its radiator fin, heat conduction block and heat conduction tube are all made of metal material, and its metal material preferably adopts the prior art Copper, iron, aluminum or aluminum alloy materials; during production, the heat sink is separated from the heat conduction block used to conduct the temperature of the heating object, and a heat conduction pipe is set in the heat conduction block at the same time, so that a section of the heat conduction pipe is embedded in the heat conduction block , so that the other section of the heat conduction pipe protrudes from the heat conduction block and is higher than the top of the heat conduction block, the closed cavity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com