Strengthened evaporation heat transferring tube

A heat transfer tube and tube body technology, applied in the field of heat transfer tubes, can solve problems such as irregular and inconsistent bending shapes, cavity shapes, inconsistent sizes, and decline in evaporation heat transfer performance, and achieve uniform structural shapes and bubble formation Consistent with the growth process, the effect of stabilizing the evaporation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

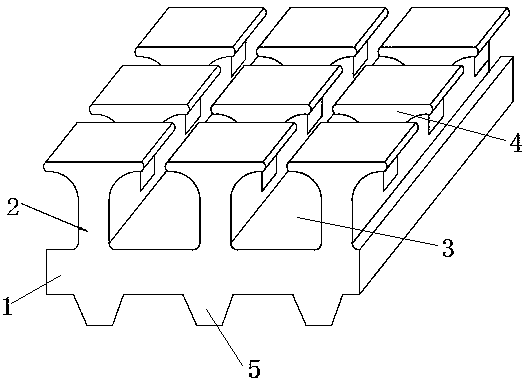

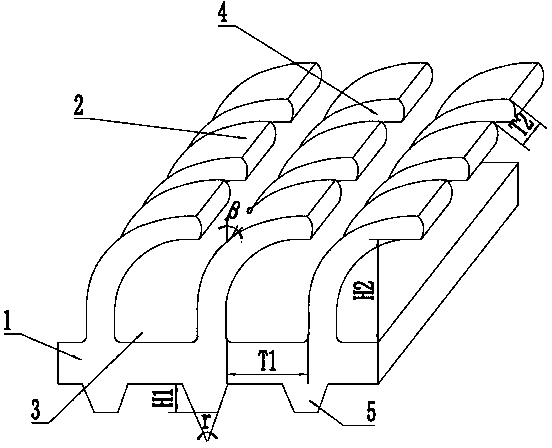

[0018] Such as figure 2 As shown, the enhanced evaporation heat transfer tube of the present invention includes an integrally formed tube body 1 and fins 2, and the fins 2 are coiled on the outer circumferential surface of the tube body 1 in a helical direction; the fins 2 are formed by cutting tools In order to uniformly bend and incline toward the axial direction of the tube body 1, the gap between the fins 2 and the tube body 1 forms a cavity 3 for evaporation; the fins 2 are provided with a plurality of fins along the circumferential direction of the tube body 1. Grooves 4, said finned grooves 4 divide the cavity 3 into a plurality of small holes.

[0019] The fins 2 are provided with 50 fins 2 per inch along the axial direction of the tube body 1, the helix angle is 1°, the height H2 of the small holes is 0.4 mm, and the number of fin grooves 4 is 150. The circumference of the small holes is The pitch T2 is 0.1mm; the inclination angle β of the fins is 45°.

[0020] Th...

Embodiment 2

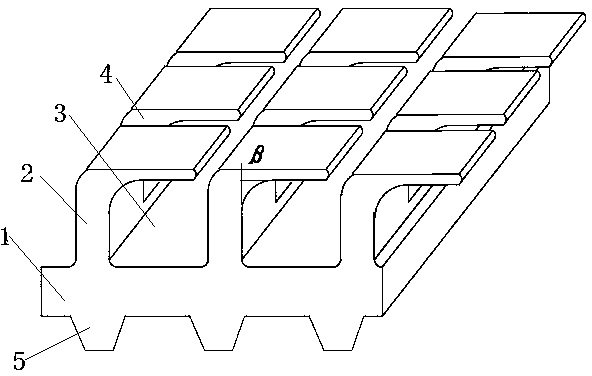

[0022] Such as image 3 As shown, the enhanced evaporation heat transfer tube of this embodiment has the same basic structure and principle as that of Embodiment 1, except that the inclination angle β of the fins is 90°. Compared with the existing heat transfer tube that directly presses the fins with a calender knife, the vertical part of the fins will not be deformed, and the shape of the holes is regular.

[0023] In the enhanced evaporation heat transfer tube of the present invention, many cavities formed by the gaps of the fins provide the vaporization core when the refrigerant evaporates, thereby strengthening the evaporation heat transfer; the ring-shaped passage formed by the cavities connected along the spiral is beneficial to the cooling of the refrigerant. The circular flow enhances the disturbance of the vapor-liquid phase when the refrigerant evaporates, thereby enhancing the heat exchange effect; the spiral fins on the circumference are divided into multiple smal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com