Liquid nitrogen cylinder, cryogenic vial storing and fetching device and liquid nitrogen cylinder storing and fetching system

An access device and liquid nitrogen tank technology, applied in the field of liquid nitrogen tanks, can solve the problems of destroying the activity of biological samples, hidden dangers to operator safety, and high error rate, and achieve high efficiency in the picking process, avoid hidden safety hazards, and reduce workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

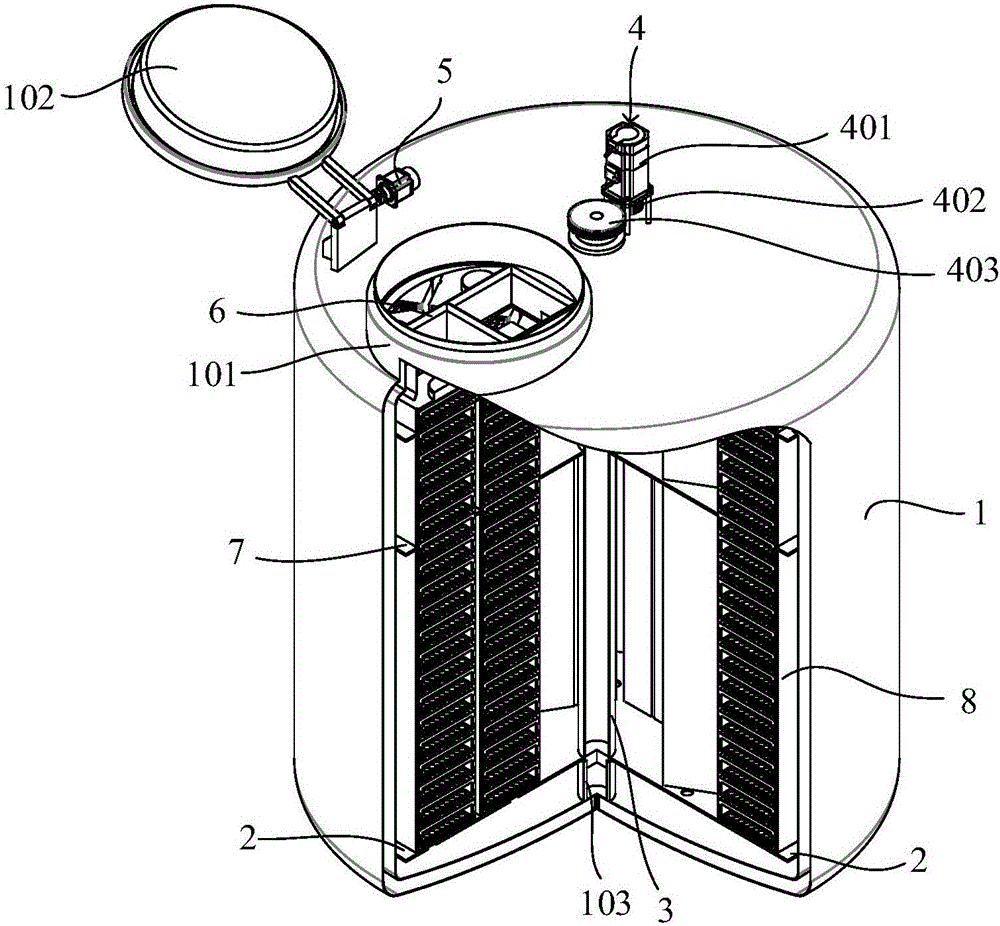

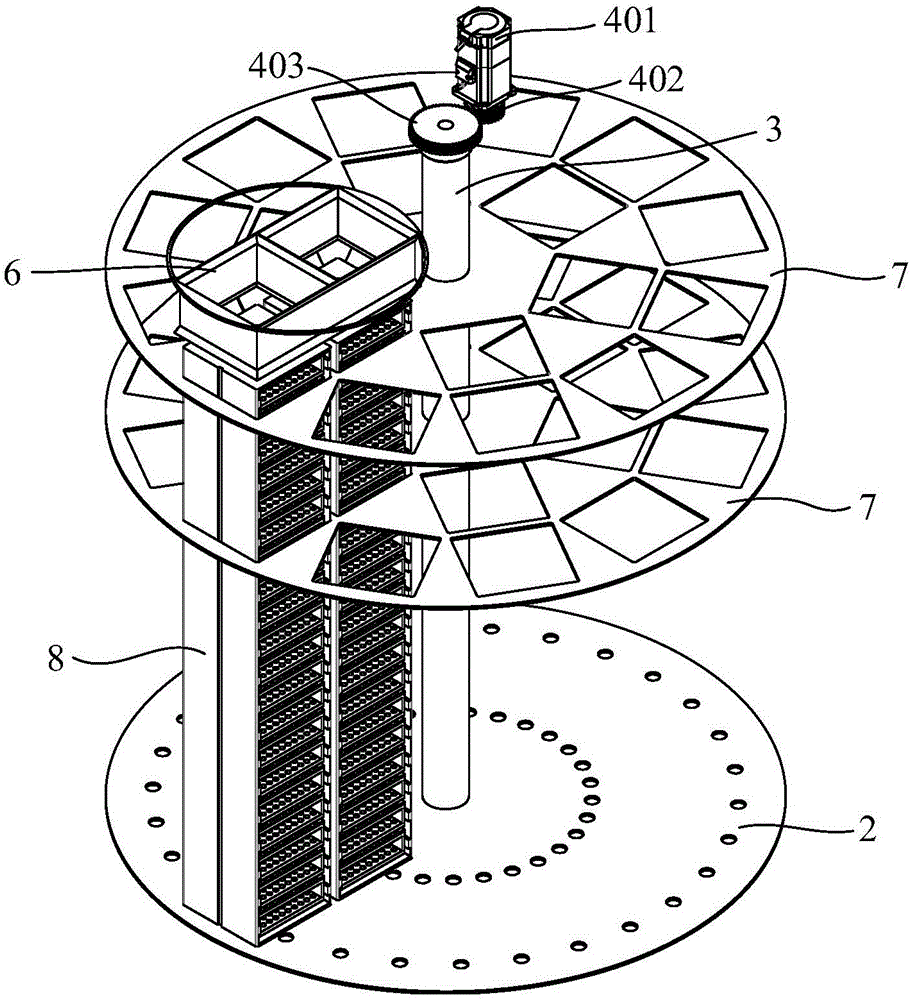

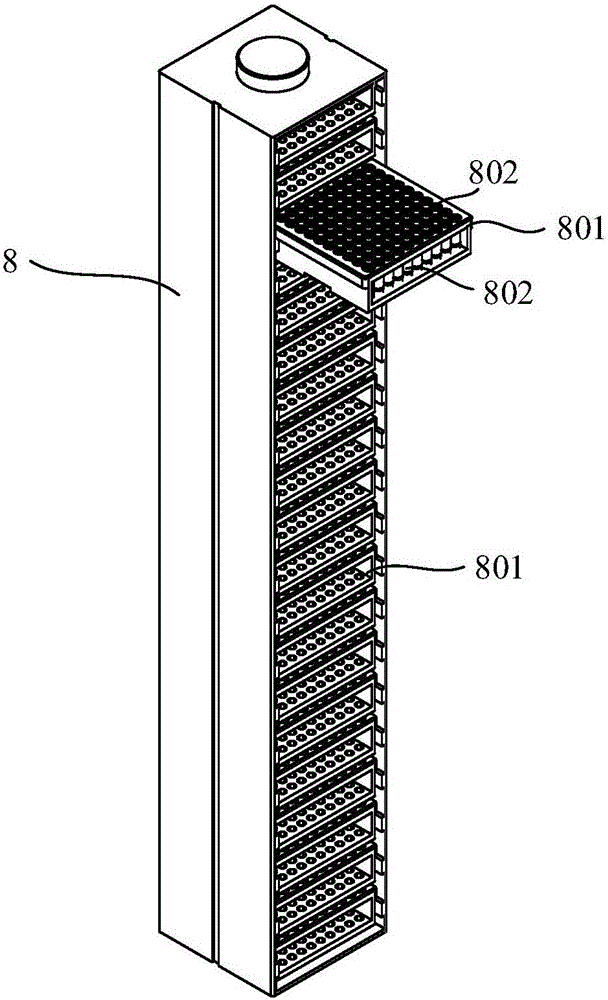

[0062] Figure 1-2 A liquid nitrogen tank is shown, including a tank body 1 , a tray 2 , a central shaft 3 and a drive assembly 4 . The lowest internal temperature of the liquid nitrogen tank can reach -196°C, and the temperature difference with the ambient temperature is very large, so the tank body 1 is generally a double-layer vacuum structure. In order to meet the requirements of material stress, the tank body 1 is designed to be arc-shaped up and down in this embodiment. The cylinder has a double-layer vacuum structure, the inner bottom of the tank body 1 is a liquid nitrogen layer, and the upper layer of the liquid nitrogen layer is a tray 2. Cryopreservation basket 8 is erected on the tray 2, such as image 3 As shown, the cryopreservation tubes 802 are arranged in an array on the cryopreservation tray 801 , and the cryopreservation trays 801 are arranged in a row and placed in the cryopreservation basket 8 . The central axis 3 is arranged vertically to the tray 2 and...

Embodiment 2

[0069] Figure 4-7 A cryotube access device is shown, which includes a housing 9, a cryotube access assembly and a docking port 901 capable of docking with an opening of a liquid nitrogen tank. In this embodiment, the liquid nitrogen tank can be a liquid nitrogen tank of the prior art. At this time, the tray needs to be manually rotated so that the target cryopreservation basket is located at the opening of the liquid nitrogen tank; the liquid nitrogen tank can also be the liquid nitrogen tank in Embodiment 1. For the nitrogen tank, there is no need to manually rotate the tray at this time, and the liquid nitrogen tank described below will be described by taking the liquid nitrogen tank in Example 1 as an example. The shell 9 of the cryopreservation tube access device is an insulated shell, and in order to ensure that the cryopreservation tube is not exposed to the external environment during extraction, such as Figure 5 As shown, the opening 101 of the liquid nitrogen tank ...

Embodiment 3

[0082] Figure 8 A storage system for a liquid nitrogen tank is shown, and the storage system for a liquid nitrogen tank includes the liquid nitrogen tank in Embodiment 1, the cryotube access device in Embodiment 2, two mobile consoles 21, and a controller (not shown in the figure). shown) and track 22. The liquid nitrogen tanks are arranged in a row in a straight line and are located on the track 22. The two mobile consoles 21 are electrically connected to the controller, and one end of the two mobile consoles 21 is respectively arranged on both sides of a liquid nitrogen tank, and the other end is arranged on the On the track 22, the mobile operating platform 21 is used for docking or disengaging the cryotube access device and the liquid nitrogen tank. A photoelectric switch (not shown) is provided at the position of each liquid nitrogen tank on the track 22, and the photoelectric switch is used to monitor the moving position of the mobile operation platform 21.

[0083] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com