Preparation method for graphene aerogel

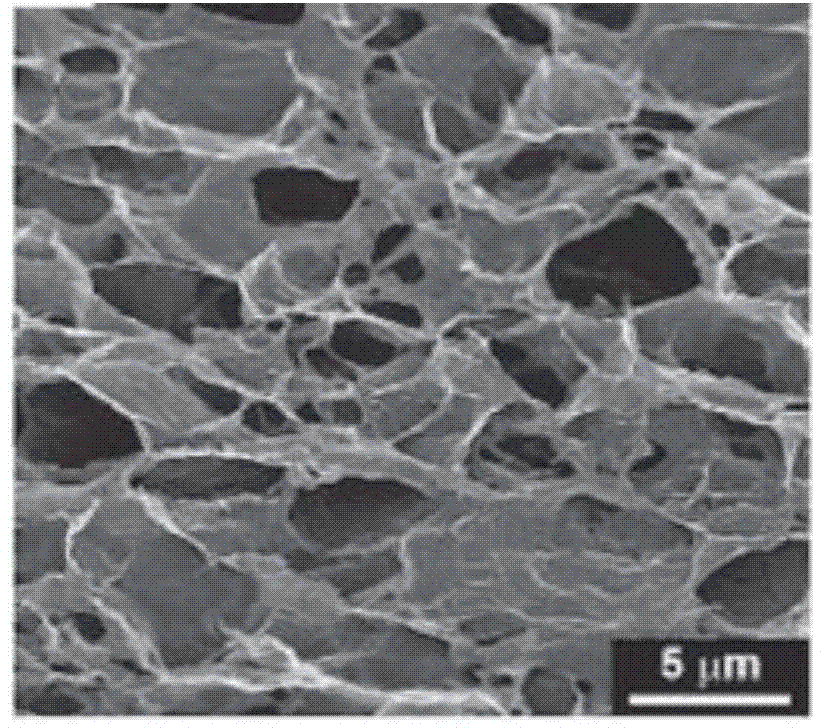

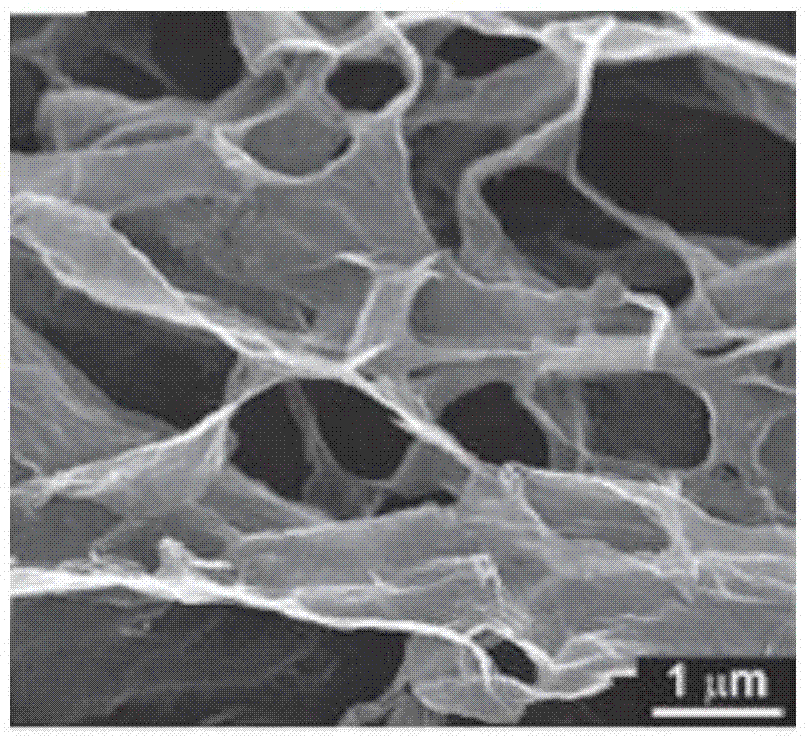

A graphene aerogel and graphene technology are applied in the preparation of supercapacitor electrode materials and in the field of graphene aerogel preparation, which can solve unstable performance, large differences in graphene aerogel structure, and unstable physical indicators. and other problems, to achieve the effect of low density, stable material performance and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Dissolve polyvinyl alcohol (PVA) in distilled water, ultrasonically disperse, and prepare 2.5mg / cm 3 Aqueous solution of polyvinyl alcohol;

[0028] (2) ultrasonically disperse the solid graphene oxide in the polyvinyl alcohol aqueous solution prepared in step (1), and prepare a concentration of 1 mg / cm 3 Graphene oxide dispersion;

[0029] (3) Take 20cm 3 The graphene oxide dispersion is subjected to liquid nitrogen freezing to obtain a frozen sample;

[0030] (4) Put the frozen sample into a freeze dryer and freeze dry it for 2 days;

[0031] (5) Put the freeze-dried sample into a porcelain cup and then put it into a vacuum drying furnace. Under the protection of a mixed gas formed by argon and hydrogen (the volume of hydrogen accounts for 5% of the volume of the mixed gas), high-temperature reduction is carried out. The temperature was controlled at 350°C for drying and heating for 3 hours, and then it was reduced at 900°C for 3 hours and cooled naturally, wh...

Embodiment 2

[0033] (1) Dissolve polyvinyl alcohol (PVA) in distilled water, ultrasonically disperse, and prepare 2.5mg / cm 3 Aqueous solution of polyvinyl alcohol;

[0034] (2) ultrasonically disperse the solid graphene oxide in the polyvinyl alcohol aqueous solution prepared in step (1), and prepare a concentration of 5 mg / cm 3 Graphene oxide dispersion;

[0035] (3) Take 20cm 3 The graphene oxide dispersion is subjected to liquid nitrogen freezing to obtain a frozen sample;

[0036] (4) Put the frozen sample into a freeze dryer and freeze dry it for 2 days;

[0037] (5) Put the freeze-dried sample into a porcelain cup and then put it into a vacuum drying furnace. Under the protection of a mixed gas formed by argon and hydrogen (the volume of hydrogen accounts for 5% of the volume of the mixed gas), high-temperature reduction is carried out. The temperature was controlled at 400°C for 3 hours, followed by high-temperature reduction at 1100°C for 3 hours and then cooled naturally, whic...

Embodiment 3

[0039] (1) Dissolve polyvinyl alcohol (PVA) in distilled water, ultrasonically disperse, and prepare 2.5mg / cm 3 Aqueous solution of polyvinyl alcohol;

[0040] (2) ultrasonically disperse the solid graphene oxide in the polyvinyl alcohol aqueous solution prepared in step (1), and prepare a concentration of 8 mg / cm 3 Graphene oxide dispersion;

[0041] (3) Take 20cm 3 The graphene oxide dispersion is subjected to liquid nitrogen freezing to obtain a frozen sample;

[0042] (4) Put the frozen sample into a freeze dryer for freeze-drying for 2 days,

[0043] (5) Put the freeze-dried sample into a porcelain cup and then put it into a vacuum drying furnace. Under the protection of a mixed gas formed by argon and hydrogen (the volume of hydrogen accounts for 5% of the volume of the mixed gas), high-temperature reduction is carried out. The temperature was controlled at 450°C for 2.5 hours, followed by high-temperature reduction at 1000°C for 3 hours and then cooled naturally to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com