High-temperature superconducting magnetic levitation motor

A technology of high-temperature superconducting and superconducting motors, applied in the usage of superconducting elements, electrical components, electromechanical devices, etc., can solve the problems of large motors with large volume and weight, large bearing friction loss, and low service life, and achieve light weight, Increased rotational speed and weight, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

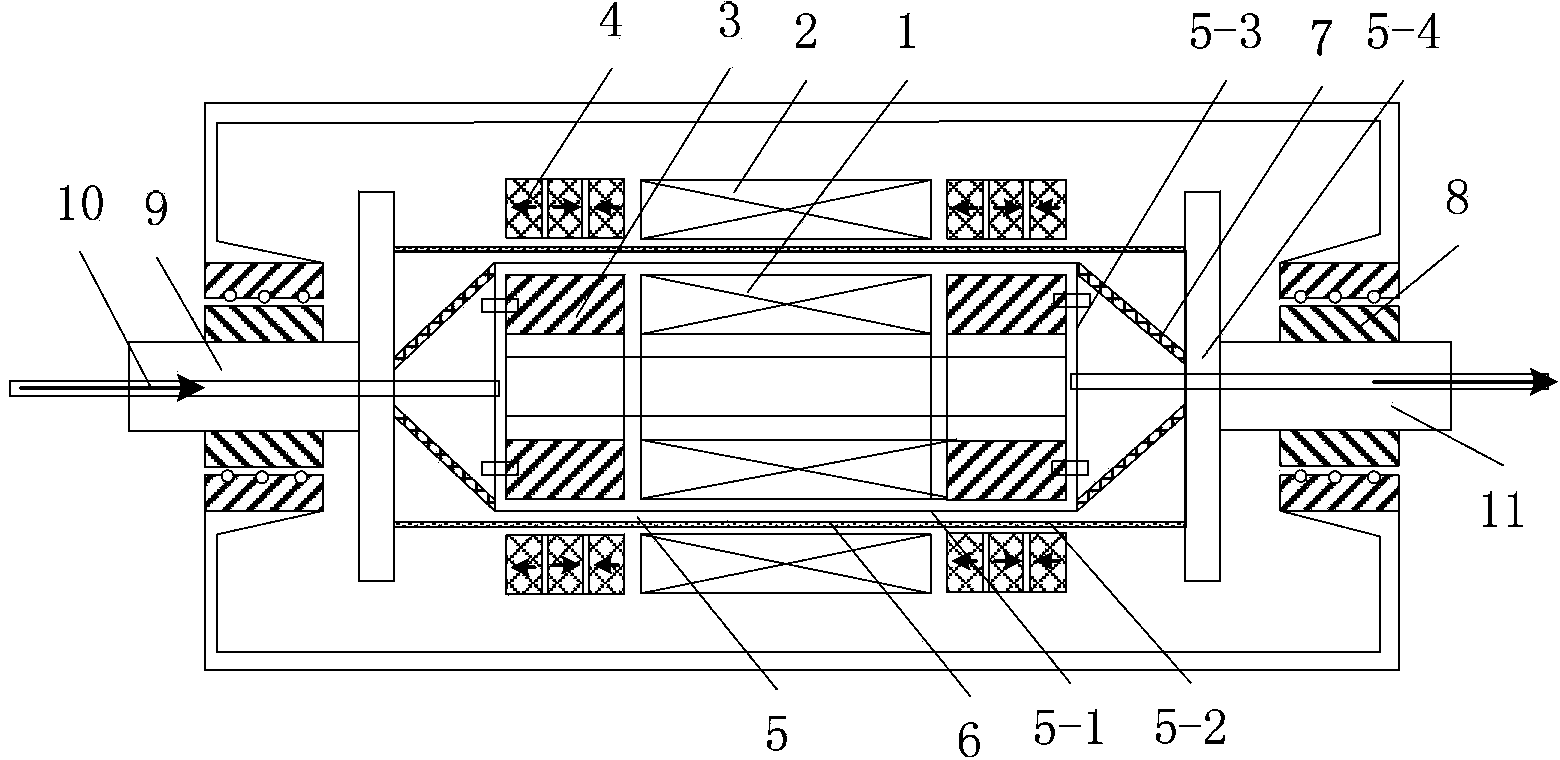

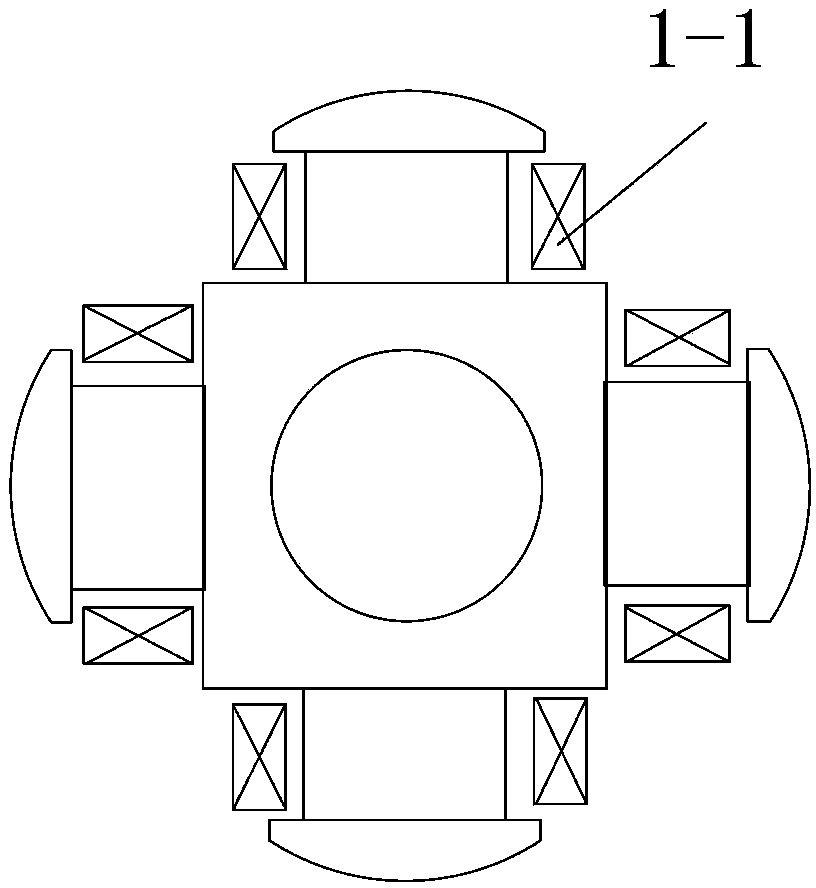

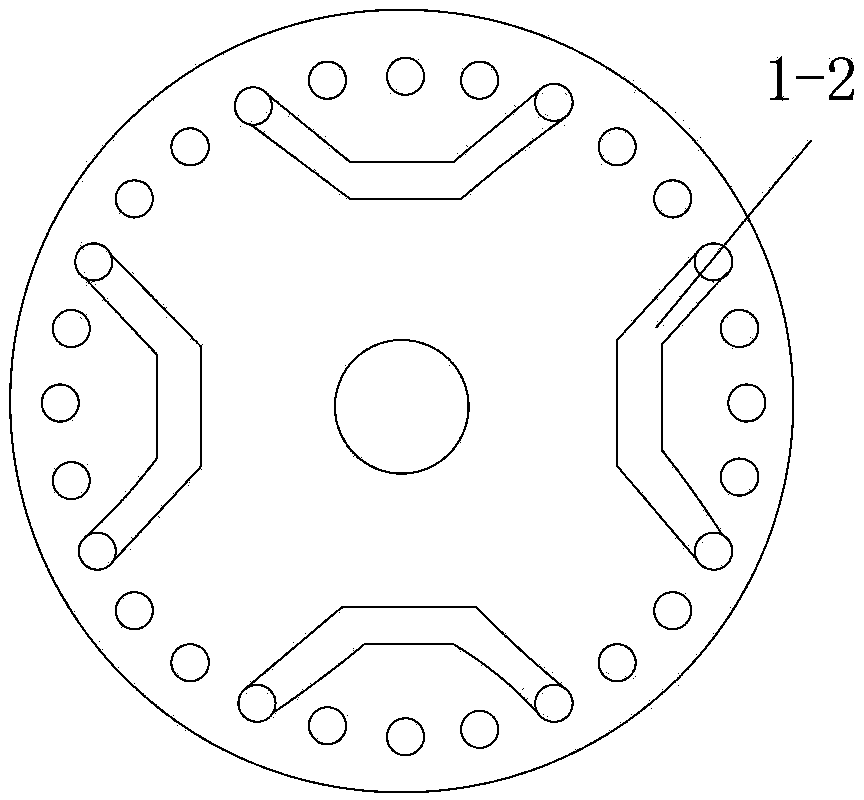

[0019] figure 1 It is a structural schematic diagram of the high-temperature superconducting magnetic levitation motor with a horizontal structure in Embodiment 1 of the present invention. Such as figure 1 As shown, the horizontal structure HTS maglev motor of the present invention consists of a superconducting motor rotor 1, a motor stator 2, a superconducting bearing rotor 3, a permanent magnetic bearing stator 4, a rotating Dewar 5, an electromagnetic shield 6, a torque tube 7, a diameter It consists of a mechanical protection bearing 8, a main shaft 9, a low-temperature liquid inlet or air inlet pipe 10, and a low-temperature liquid outlet or air outlet pipe 11. The superconducting motor rotor 1 and the superconducting bearing rotor 2 are placed in a rotating Dewar 5 and cooled by liquid nitrogen, liquid neon, liquid helium or cold helium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com