Infrastructure-independent deepwater oil field development concept

a deepwater oil field and infrastructure technology, applied in the direction of passenger handling equipment, lighting and heating equipment, borehole/well accessories, etc., can solve the problems of not being able to operate tankers during the day, the use of seabed pipeline systems for transporting hydrocarbons to shore may not be economically feasible, and the construction of pipelines to shore is typically not practicabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

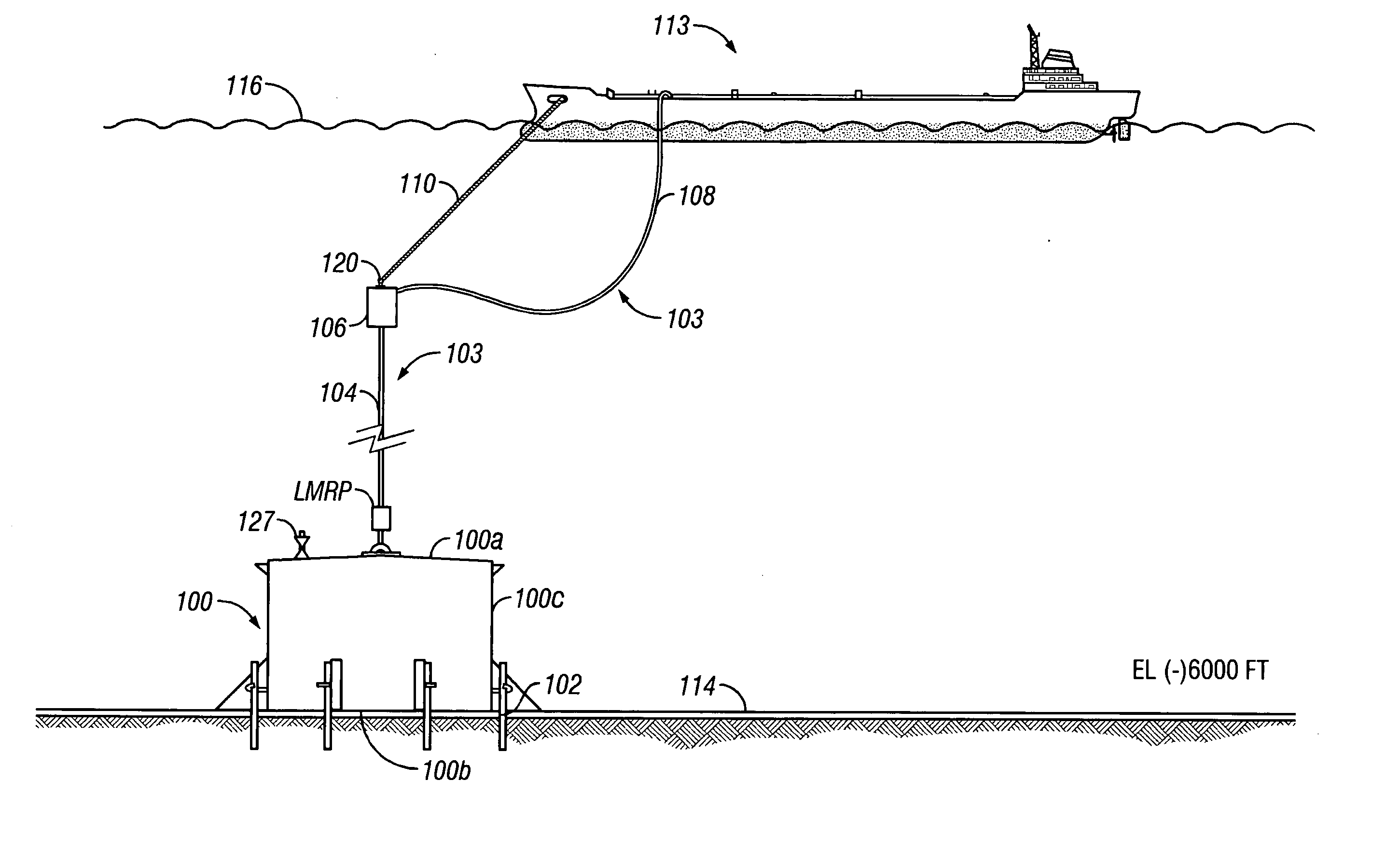

[0038] Referring to the drawings wherein like reference characters are used for like parts throughout the several views, FIG. 4 shows one embodiment of a seabed pertains subsea storage hydrocarbon storage and offtake system in accordance with the present invention. The storage and offtake system comprises a storage tank 100 adapted for placement on and, possibly, attachment to, the seabed 114. The tank 100 comprises a top 100a, a bottom 100b, and one or more side walls 100c. At the base of the tank 100, there is an amount of fixed ballast, such as sand, concrete or other dense material, to provide submerged weight to overcome the buoyancy force of the hydrocarbon when the tank 100 is filled to its maximum storage capacity. In the embodiment shown, the tank 100 rests on the sea floor at a depth of approximately 6000 feet.

[0039] The tank may comprise any configuration as determined by one skilled in the art, including cylindrical-shaped, box-shaped, or the like. Those skilled in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com