High-flowability high-glossiness no-surface-defect colored metallic-pearl-effect spraying-free polypropylene automobile material and preparation method thereof

A color metal and pearlescent effect technology, applied in the field of polymer materials, can solve the problems of affecting uniform plasticization, limited application range, lack of high flow and colored pearlescent effect, etc., and achieve the effect of improving gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

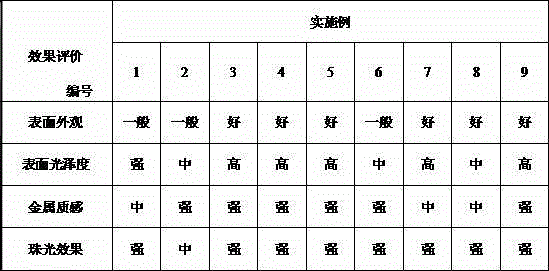

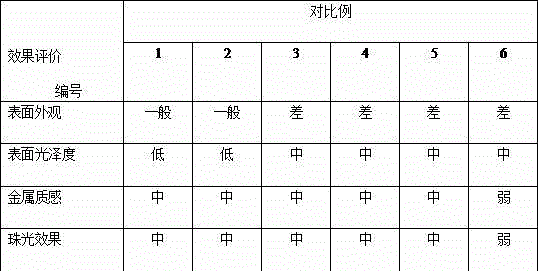

Examples

Embodiment 1

[0045] The high-flow, high-gloss, non-surface-defect colored metallic pearlescent effect spray-free polypropylene automobile material of the present embodiment is composed of the following materials by weight percentage:

[0046] Polypropylene is high melt flow rate polypropylene, and the melt flow rate of polypropylene is 60g / 10min, 71.8%;

[0047] Toughening agent is ethylene-octene copolymer, 3%;

[0048] The mineral masterbatch is talc masterbatch, 5%;

[0049] The compatibilizer is maleic anhydride grafted polypropylene, 5%;

[0050] Antioxidants are 1010, 0.2%, 168, 0.2%;

[0051] Light stabilizer is 944, 0.6%;

[0052] The lubricant is polyethylene wax, 1.2%;

[0053] Surface modifier, 6%;

[0054] Color metal pigment masterbatch is color zinc powder pigment masterbatch, 3%;

[0055] The pearlescent masterbatch is a mica-coated pearlescent pigment masterbatch, 4%.

[0056] The specific preparation method includes the fo...

Embodiment 2

[0060] The high-flow, high-gloss, non-surface-defect colored metallic pearlescent effect spray-free polypropylene automobile material of the present embodiment is composed of the following materials by weight percentage:

[0061] Polypropylene is high melt flow rate polypropylene, and the melt flow rate of polypropylene is 70g / 10min, 63.9%;

[0062] Toughening agent is ethylene-octene copolymer, 4%;

[0063] The mineral masterbatch is calcium carbonate masterbatch, 10%;

[0064] The compatibilizer is maleic anhydride grafted polyethylene, 6%;

[0065] Antioxidants are 1010, 0.3%, 168, 0.2%;

[0066] Light stabilizers are 944, 0.2%, 770, 0.4%;

[0067] The lubricant is polyethylene wax, 0.4%, calcium stearate, 0.6%;

[0068] Surface modifier, 7%;

[0069] The color metal pigment masterbatch is a commercially available silver powder pigment masterbatch, 4%;

[0070] Pearlescent masterbatch is silica-coated pearlescent pigment maste...

Embodiment 3

[0073] The high-flow, high-gloss, non-surface-defect colored metallic pearlescent effect spray-free polypropylene automobile material of the present embodiment is composed of the following materials by weight percentage:

[0074] Polypropylene is high melt flow rate polypropylene, and the melt flow rate of polypropylene is 120g / 10min, 55.7%;

[0075] Toughening agent is ethylene-propylene copolymer, 2%;

[0076] The mineral masterbatch is talc masterbatch, 15%;

[0077] The compatibilizer is maleic anhydride grafted polypropylene, 8%;

[0078] Antioxidants are 1010, 0.2%, 168, 0.3%;

[0079] Light stabilizers are 944, 0.4%, 770, 0.2%;

[0080] The lubricant is polyethylene wax, 0.4%, calcium stearate, 0.4%, ethylene bis-stearate amide, 0.4%;

[0081] Surface modifier, 8%;

[0082] Color metal pigment masterbatch is color zinc powder pigment masterbatch, 4%;

[0083] Pearlescent masterbatch is mica coated pearlescent pigment mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com