Thin-wall ring part machining method and automatic auxiliary supporting device thereof

A technology for auxiliary support and processing methods, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problem of low degree of automation, no comprehensive consideration of workpiece deformation release and wall thickness requirements, weak rigidity of thin-walled ring parts, etc. problems, achieve high precision, small processing deformation, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

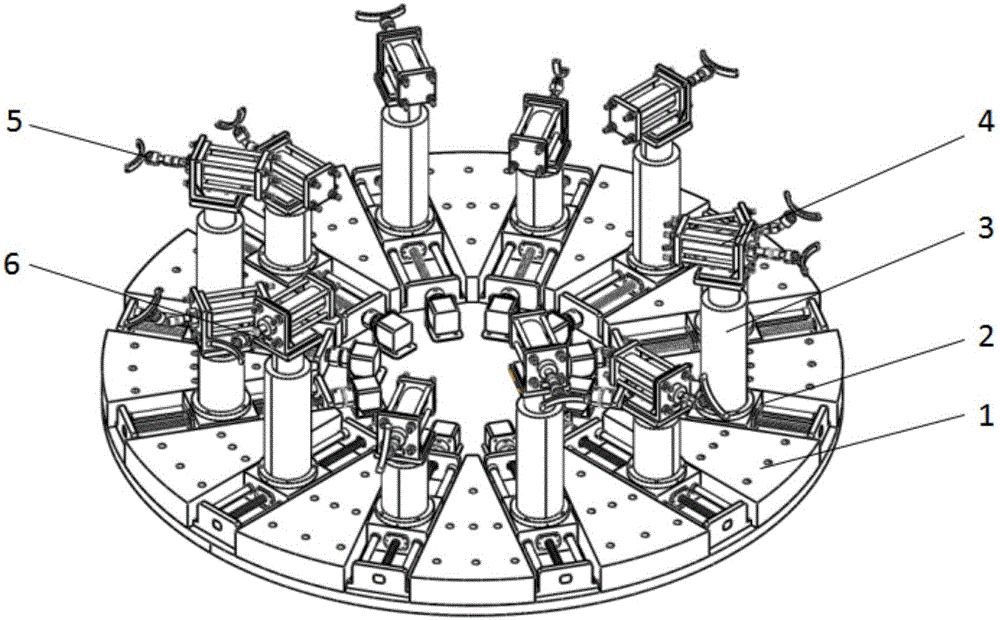

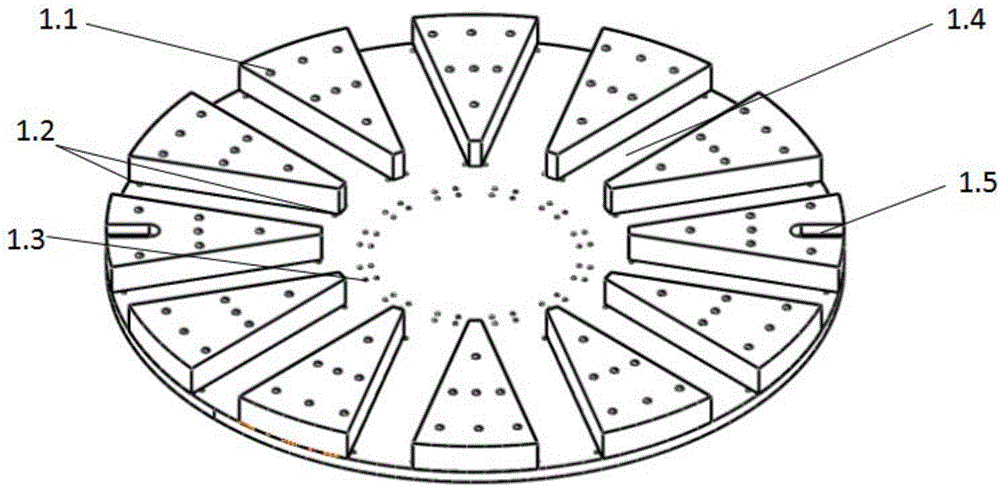

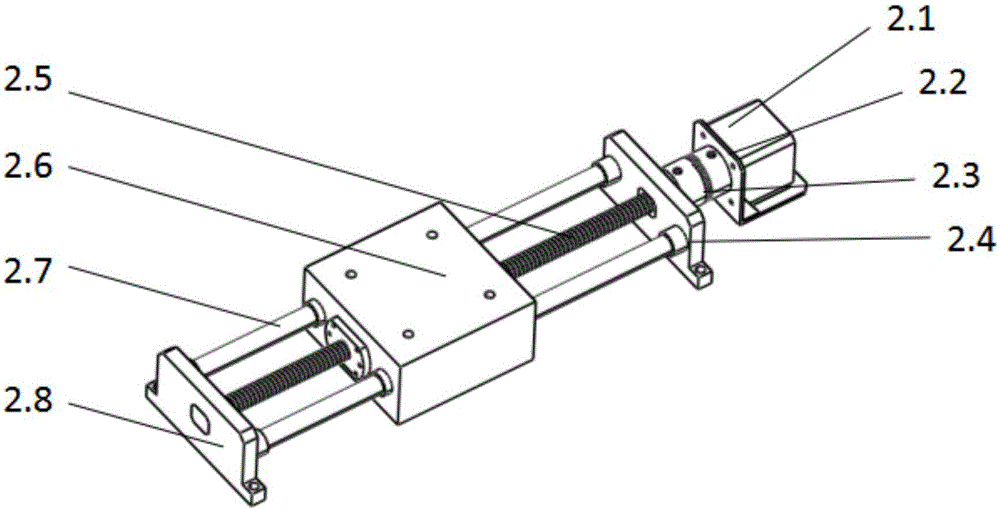

[0032] Such as figure 1 .

[0033] An automatic auxiliary support device for processing thin-walled ring parts, which includes: a base 1 ( figure 2 ), transmission mechanism 2 ( image 3 ), Z-direction lifting platform 3 (such as Figure 4 ), radial auxiliary support 4 ( Figure 5 ), force sensor 5 and distance sensor 6, its assembly diagram is as follows figure 1 As shown; the base 1 is a ring-shaped fixture main body installation platform, which is connected with the machine tool workbench through screws and pressure plates. The base 1 is provided with a positioning notch 1.5 for positioning when installing thin-walled ring parts and multiple uniformly distributed for installation The installation groove 1.4 of the transmission mechanism 2; the transmission mechanism 2 is radially installed in the installation groove 1.4 of the base 1 and can move radially in the installation groove 1.4 to realize the radial position adjustment of the radial auxiliary support 4; the Z-dir...

Embodiment 2

[0036] A method for processing a thin-walled ring, the specific implementation of which is as follows: Figure 7 The thin-walled annular part 7 shown is a casing of an aero-engine combustion chamber. When processing this part, the blank is firstly fixed on the base of the automatic auxiliary support device through the positioning of the seam and the pressing of the pressure plate, and the movement of each transmission mechanism is controlled. At D=300mm, rough machining is carried out on the inner surface of the blank, such as Figure 8 As shown, at this time the workpiece support surface machining allowance a = 5mm. The distance L between the workpiece support surface and each radial auxiliary support fixed bracket is measured by the distance sensor on the automatic auxiliary support device, and the difference between the measured maximum and minimum values ΔL=0.5mm is less than the machining allowance a of the support surface, and each control The radial auxiliary support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com