Patents

Literature

36 results about "Straw tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

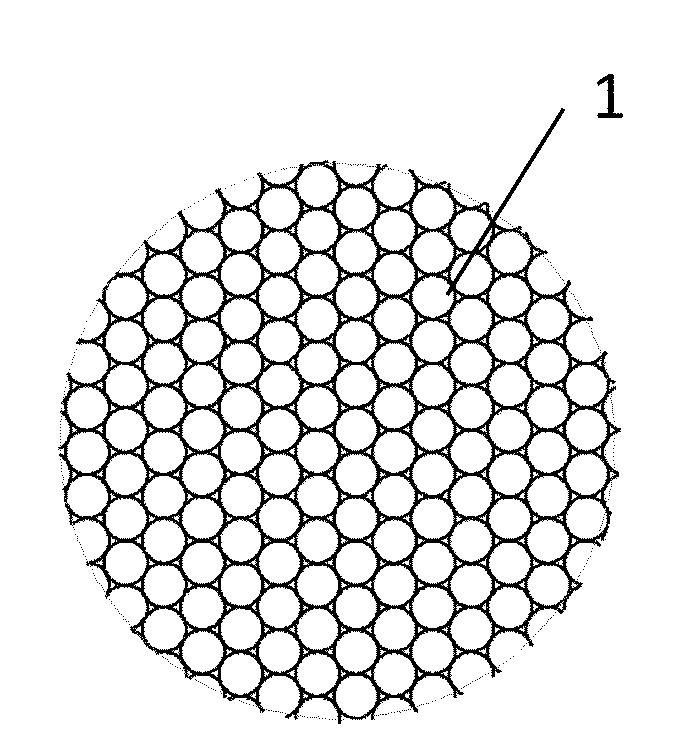

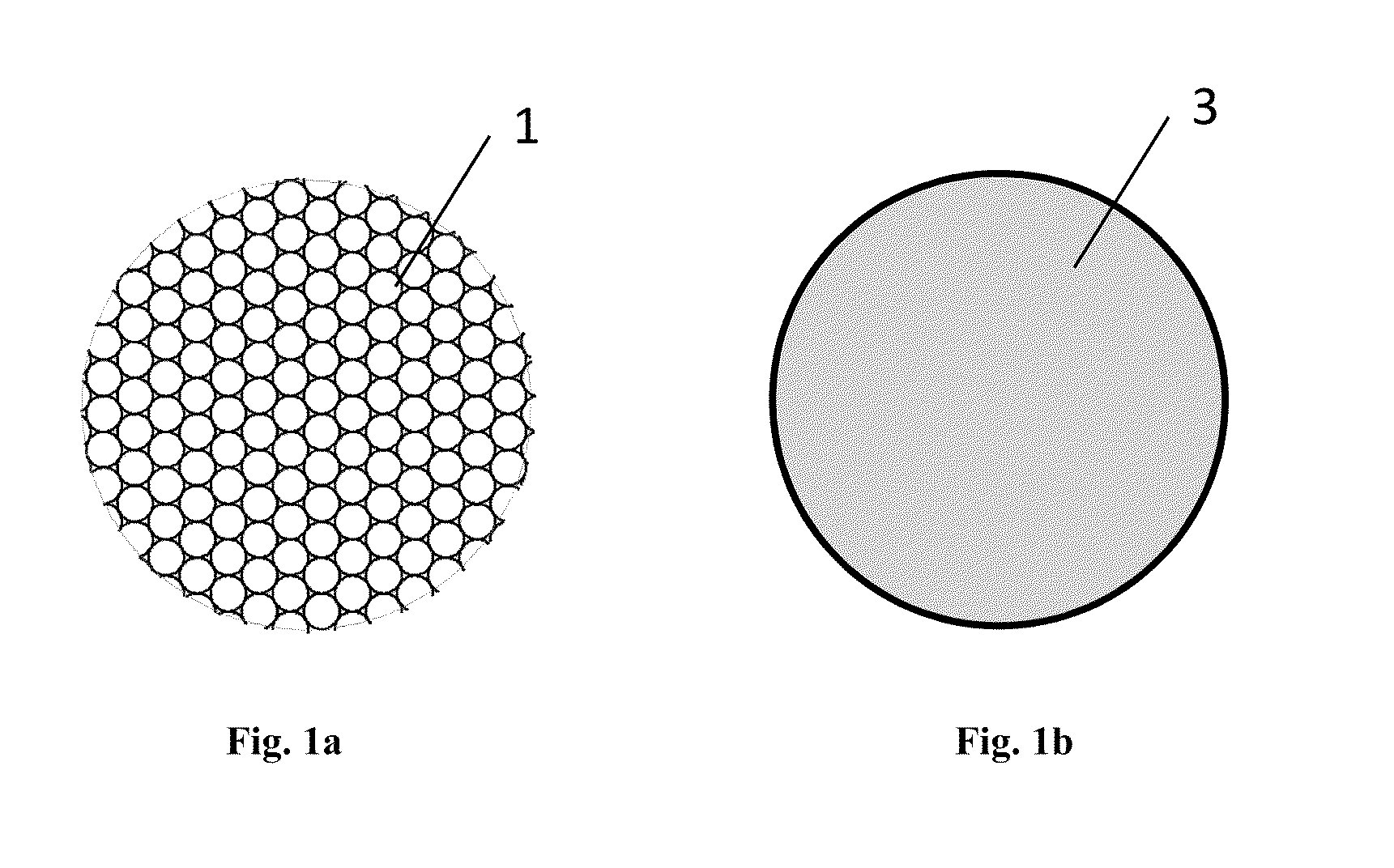

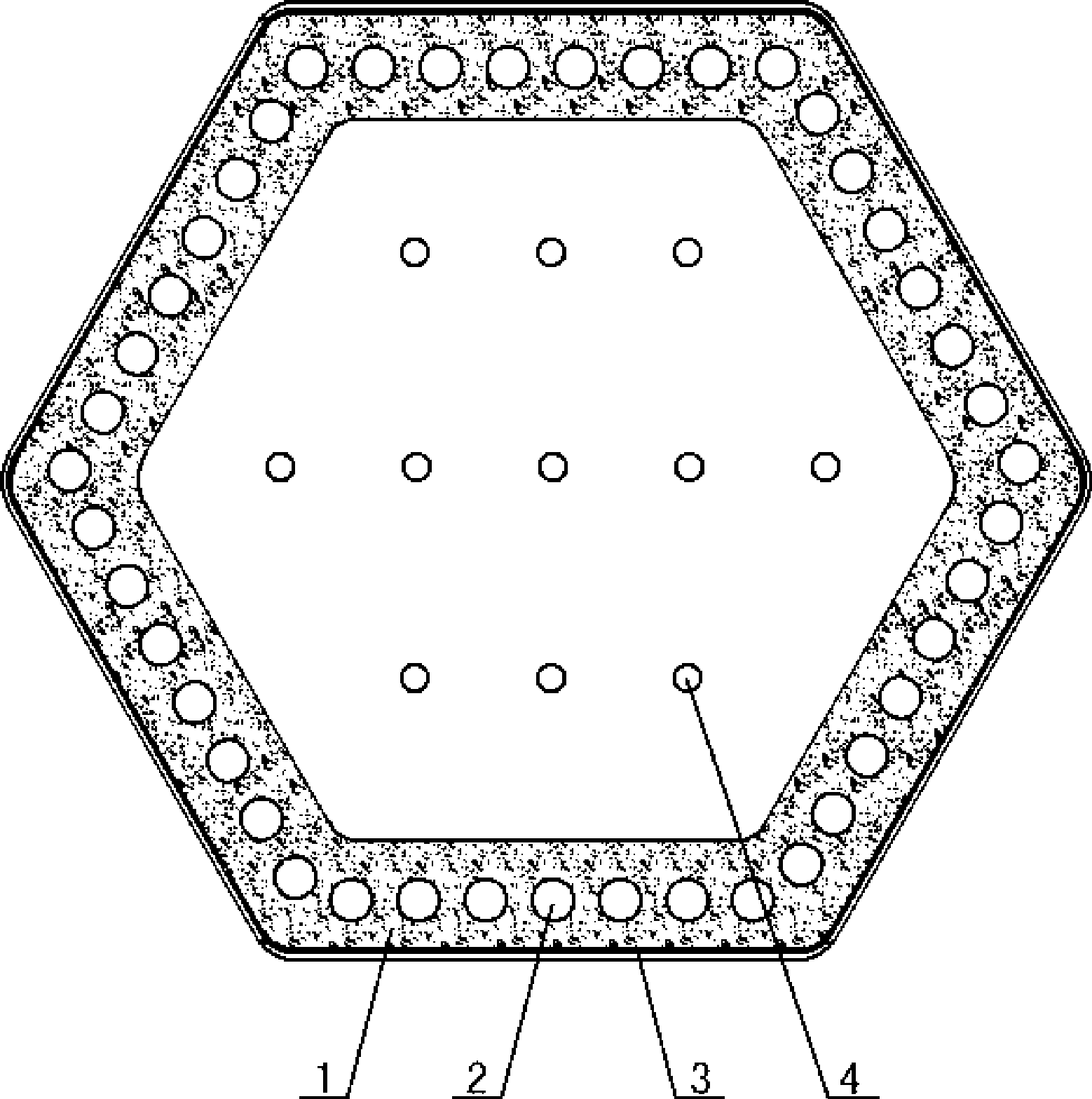

Boron coated straw neutron detector

ActiveUS7002159B2Sensitive to radiationImpression capsElectric discharge tubesElectronCharge division

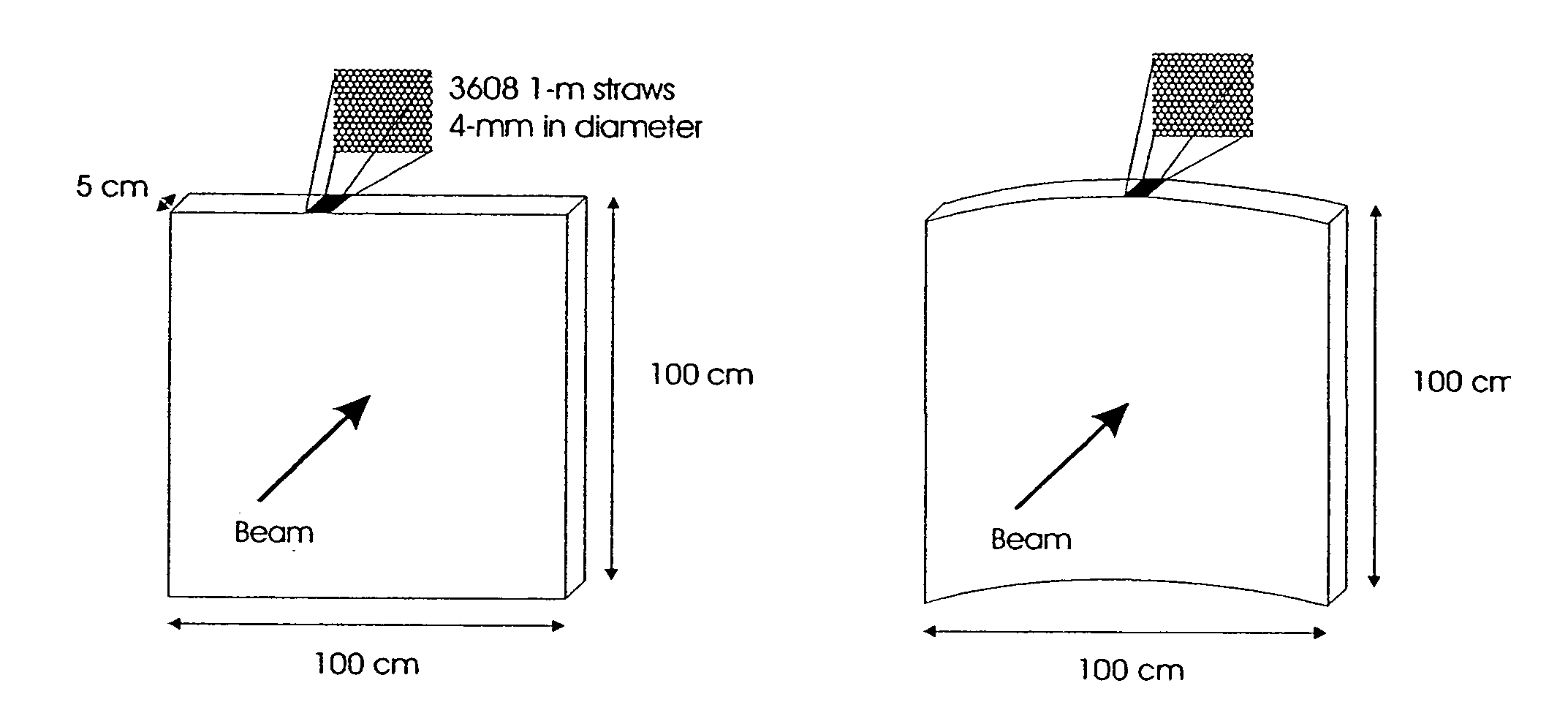

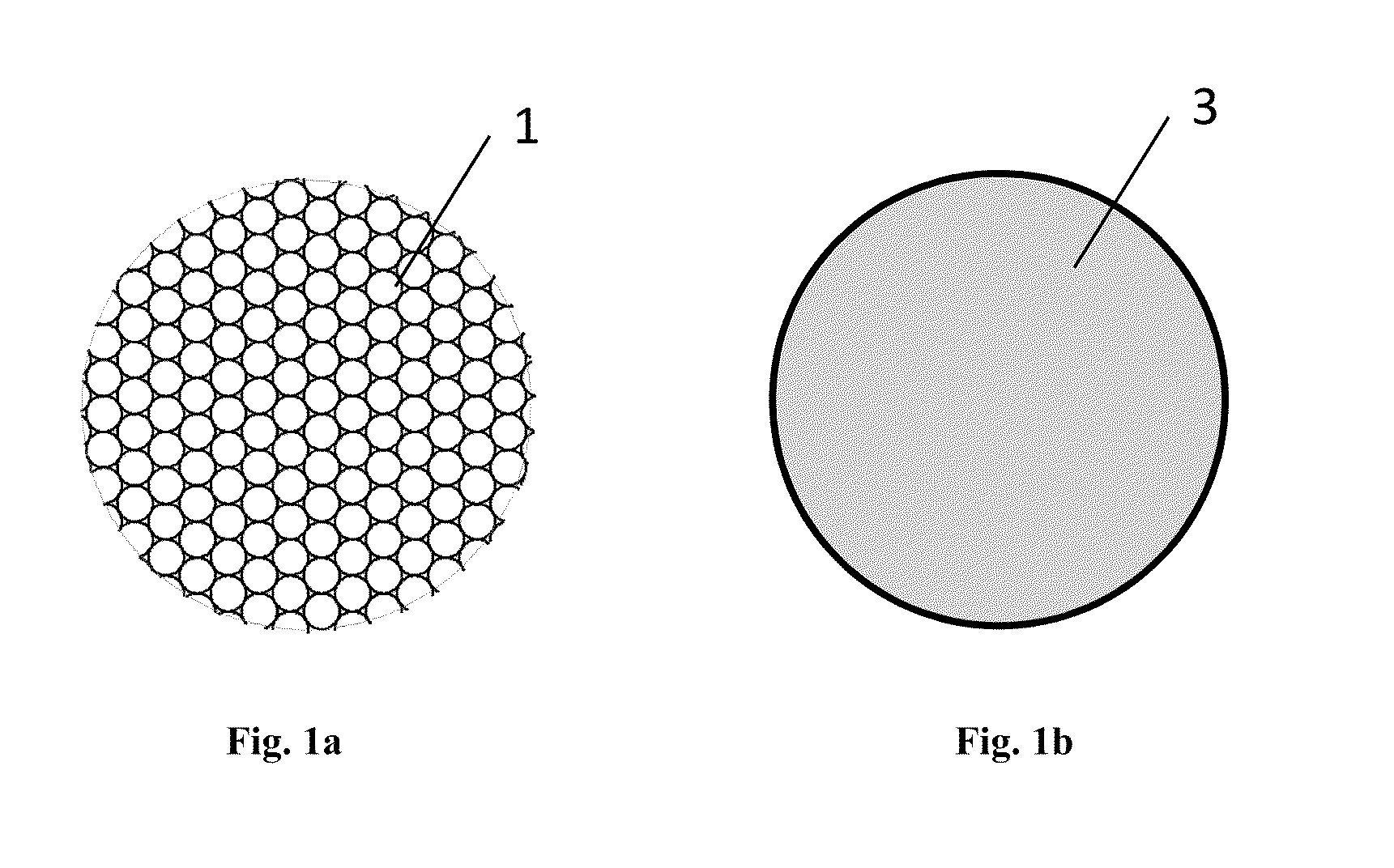

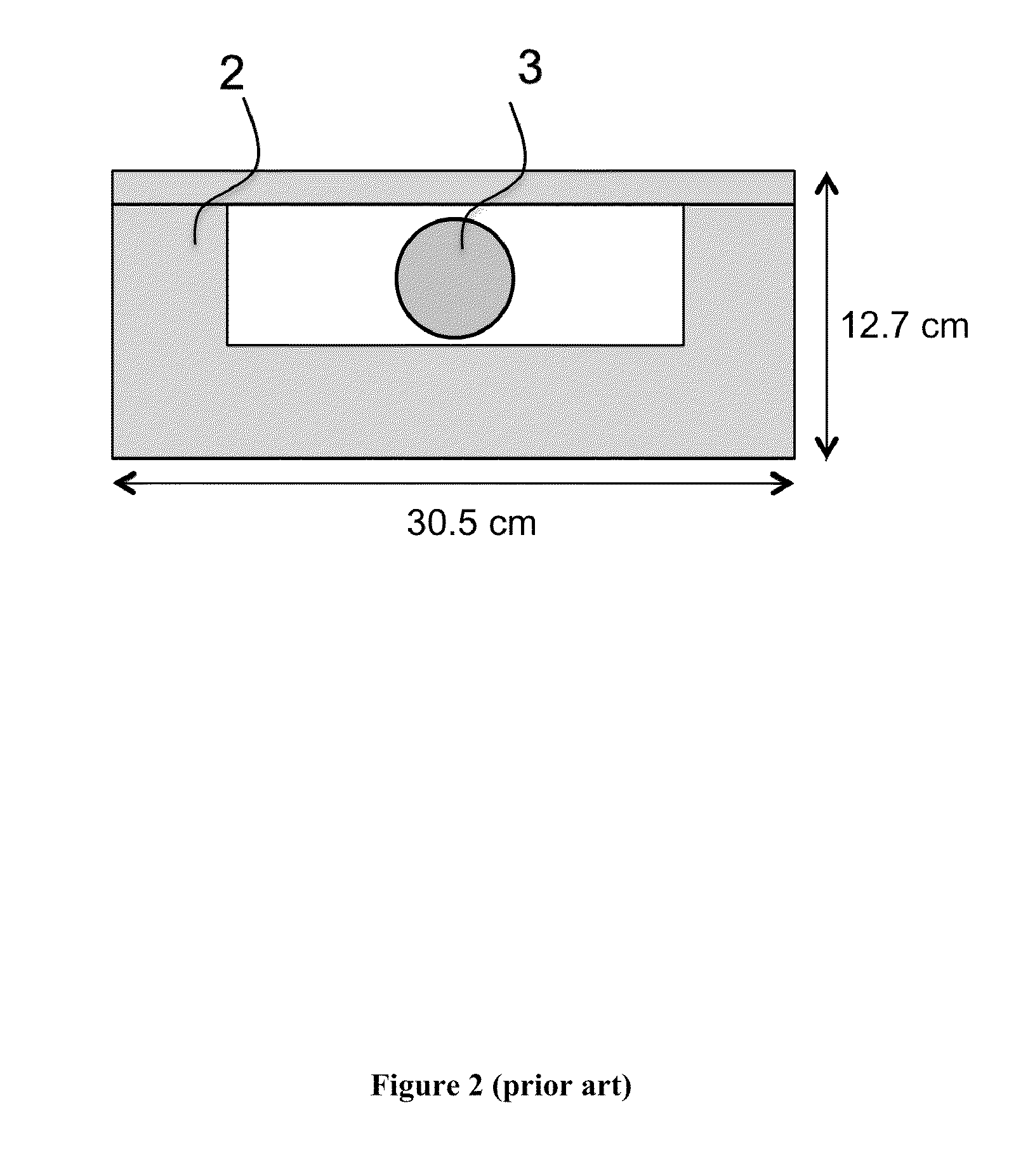

A neutron detector technology based on 10B thin film conversion of neutrons and detection of neutron capture reaction products in a counter gas within a thin straw tube detector body is described. This neutron detector is based on gas-filled thin wall straw tubes, modified for the conversion of neutrons in a very thin coating, or layer, of 10B, applied for example as a sputter-coated film of 10B4C, that lines the interior, or inside of the straw tube surface; and the subsequent detection of the neutron reaction products in the counter gas. One embodiment of this invention employs a closely-packed array of 10B4C-lined straw tubes employing a very thin and therefore high efficiency 10B4C layer, hence removing the barrier to efficient neutron capture reaction product escape while still providing for efficient neutron capture by providing a plurality of very thin 10B converters, each individual converter element providing efficient reaction product escape. Using such densely packed straw tube detectors of small diameter, a reasonable stack depth allows a high neutron detection efficiency to be achieved on the 1–10Å wavelength range of thermal neutrons. The position of each interacting neutron can be accurately obtained with for example, resistive charge division readout combined with straw decoding electronics to determine the identity of the struck straw.

Owner:PROPORTIONAL TECH

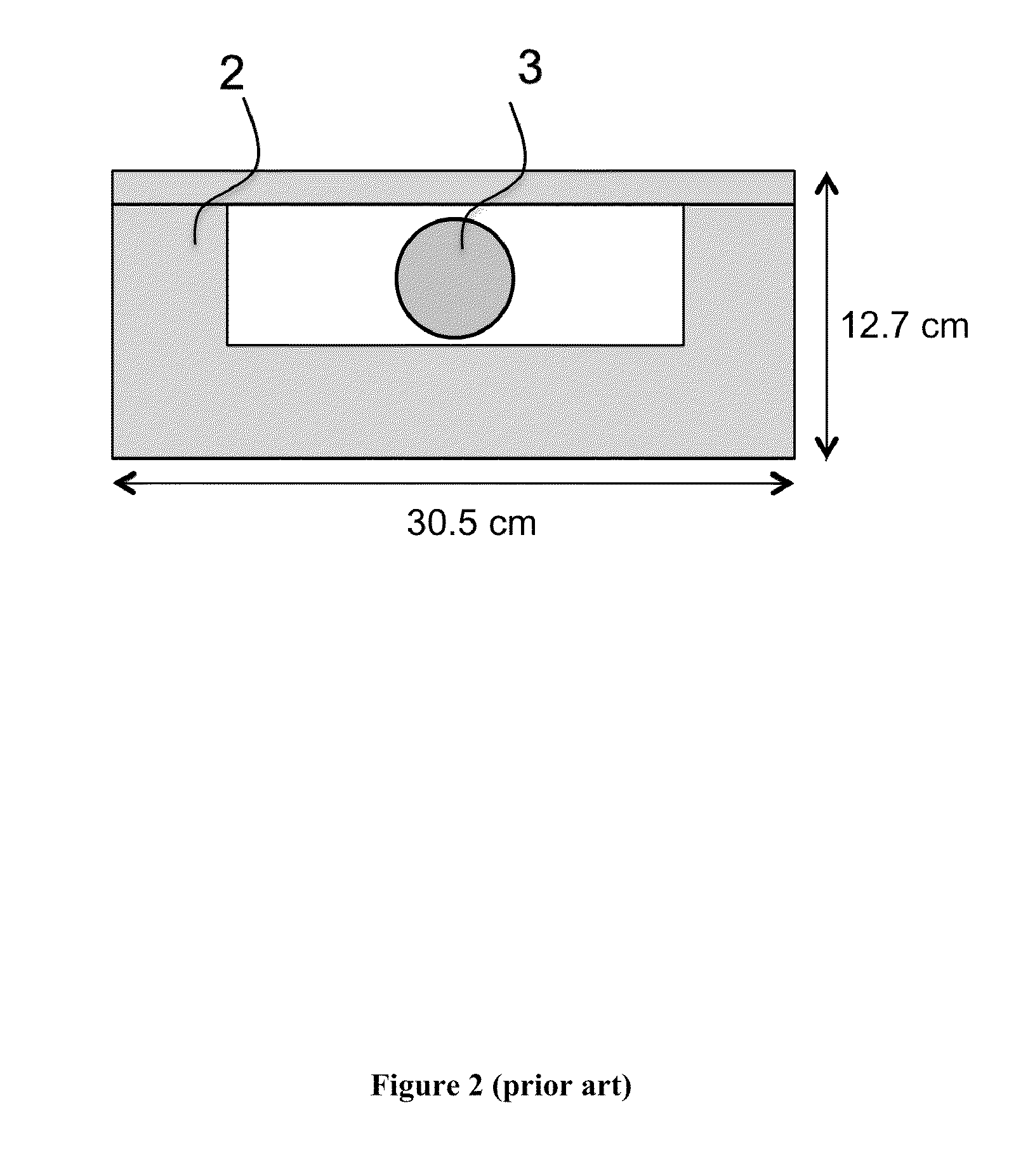

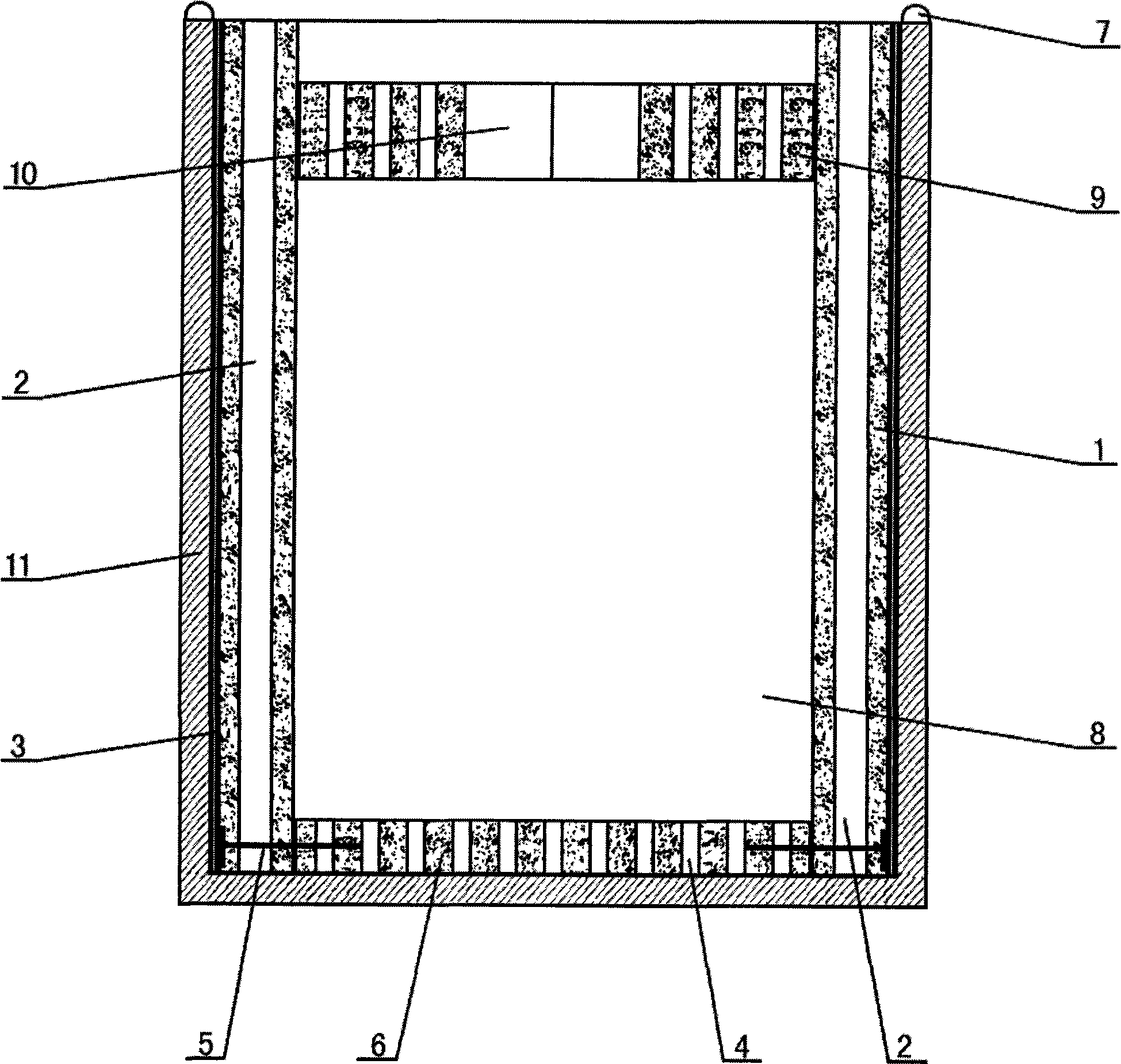

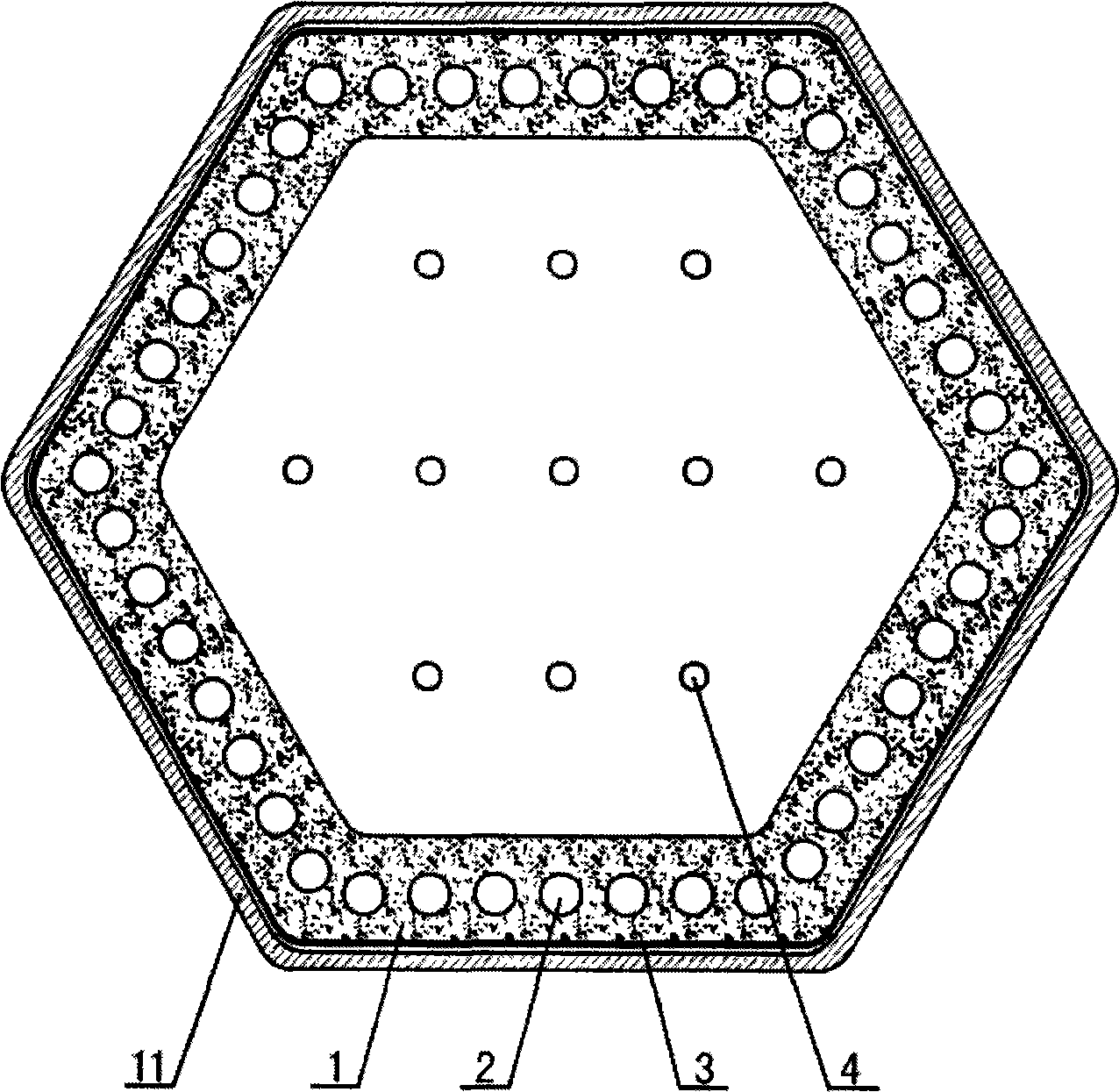

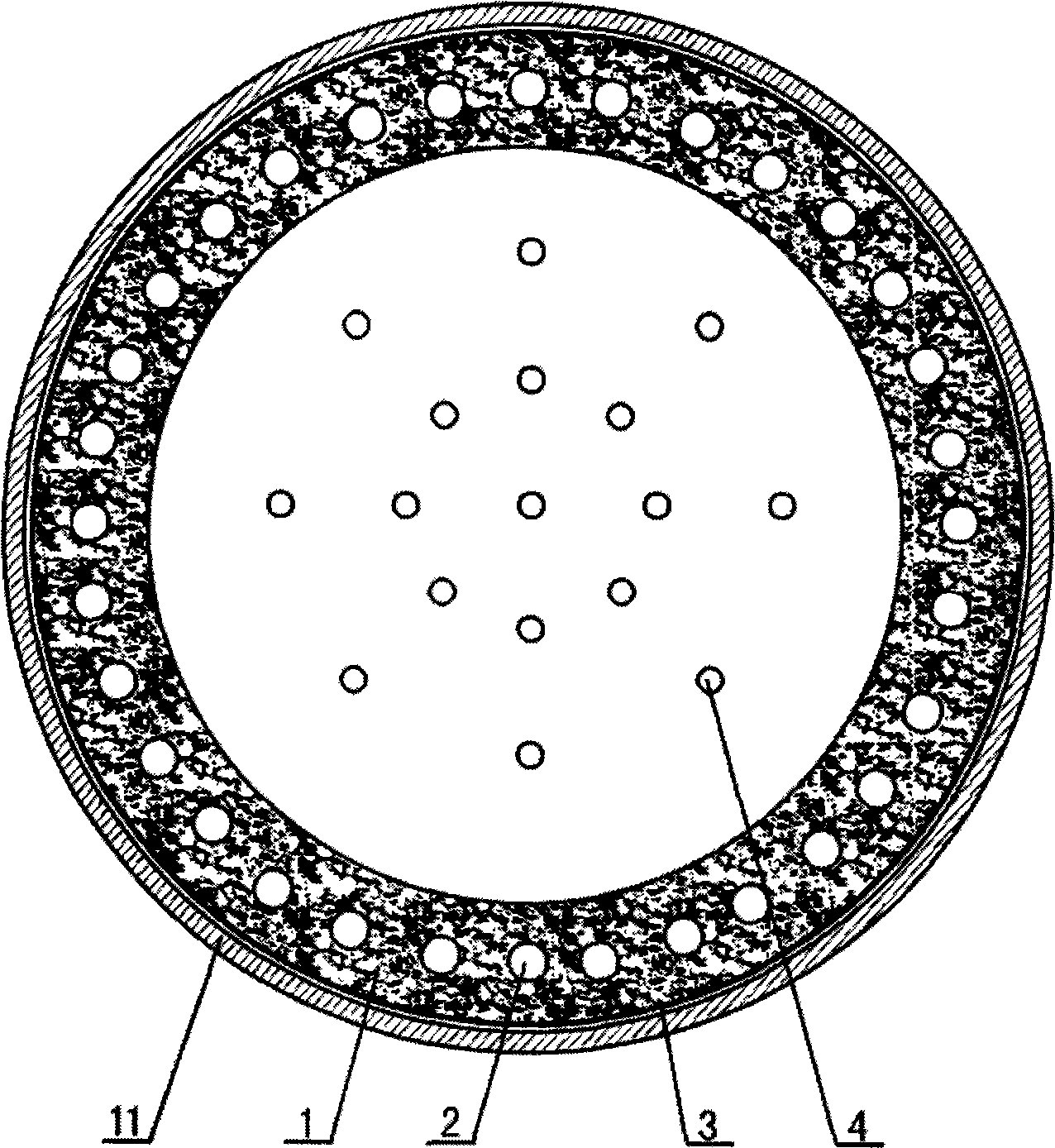

Optimized Detection of Fission Neutrons Using Boron Coated Straw Detectors Distributed in Moderator Material

InactiveUS20100301226A1Efficient detectionEasy to detectMaterial analysis by optical meansNeutron radiation measurementFission neutronElectrical impulse

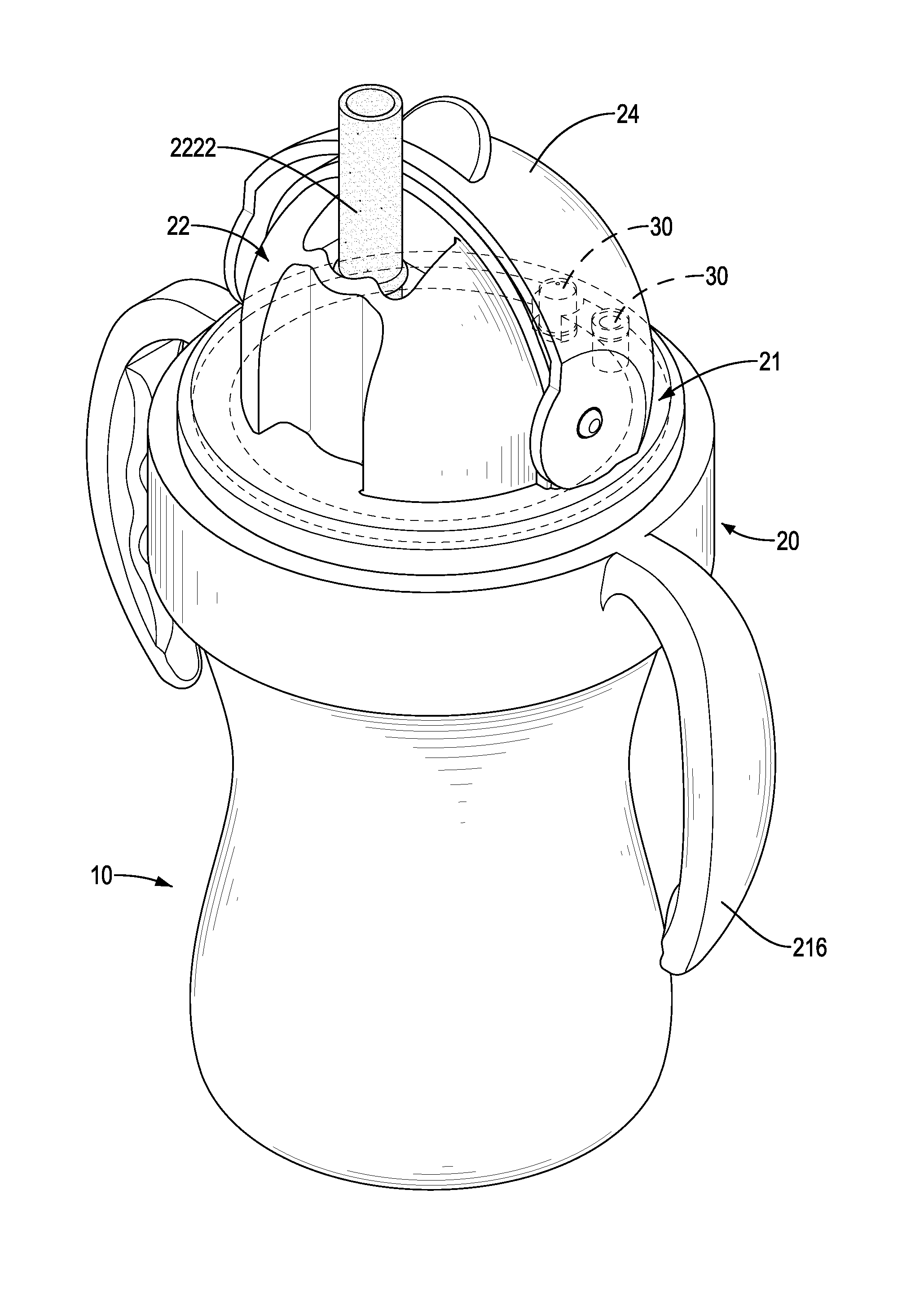

The present invention includes an apparatus and method for neutron radiation detection. The apparatus comprises combining thin walled, boron-coated straw tubes with a plastic moderator material interspersed around the tubes. The method involves using such an apparatus through application of voltage to a central wire running inside the tubes and collecting electrical pulses generated thereby.

Owner:PROPORTIONAL TECH

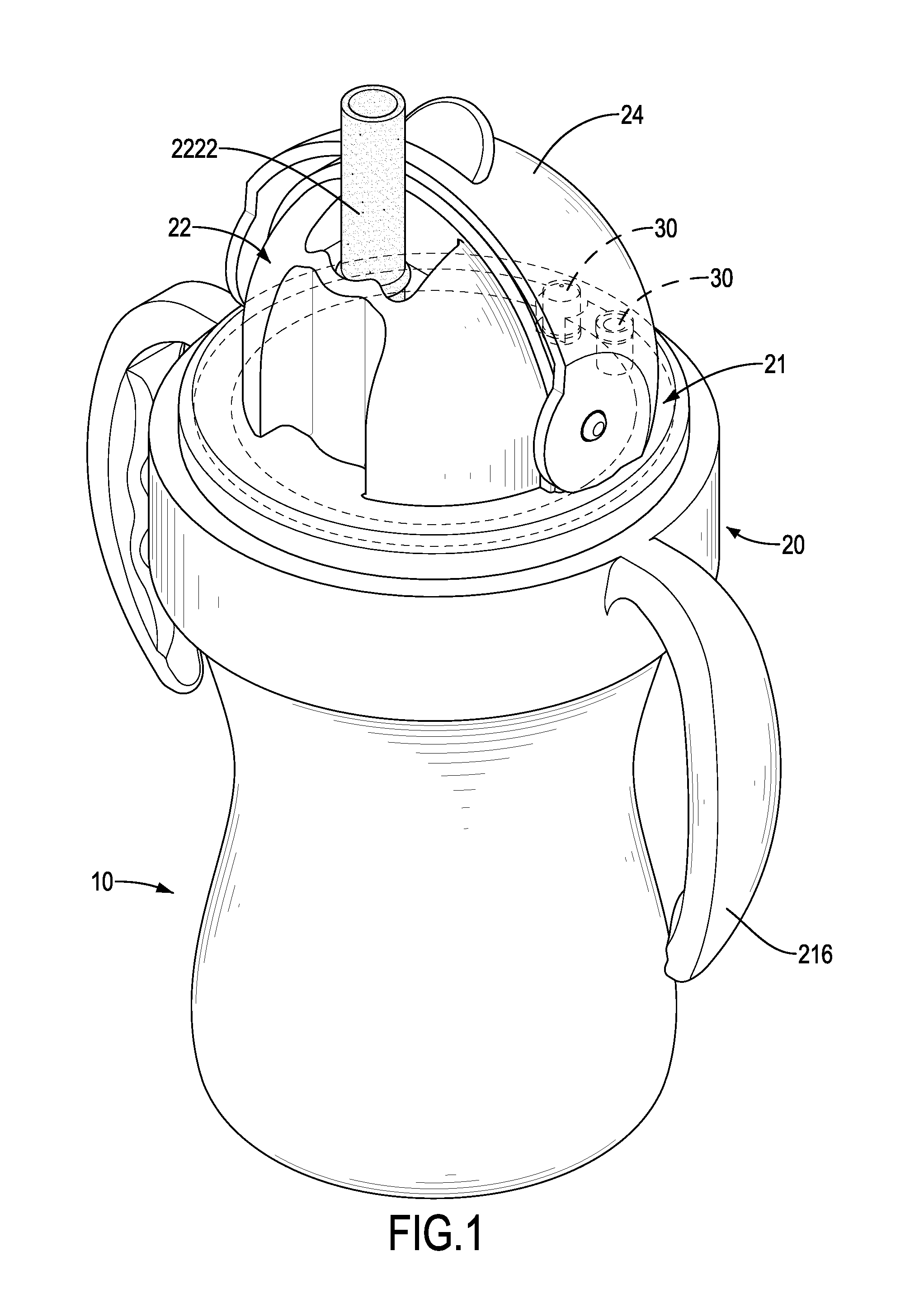

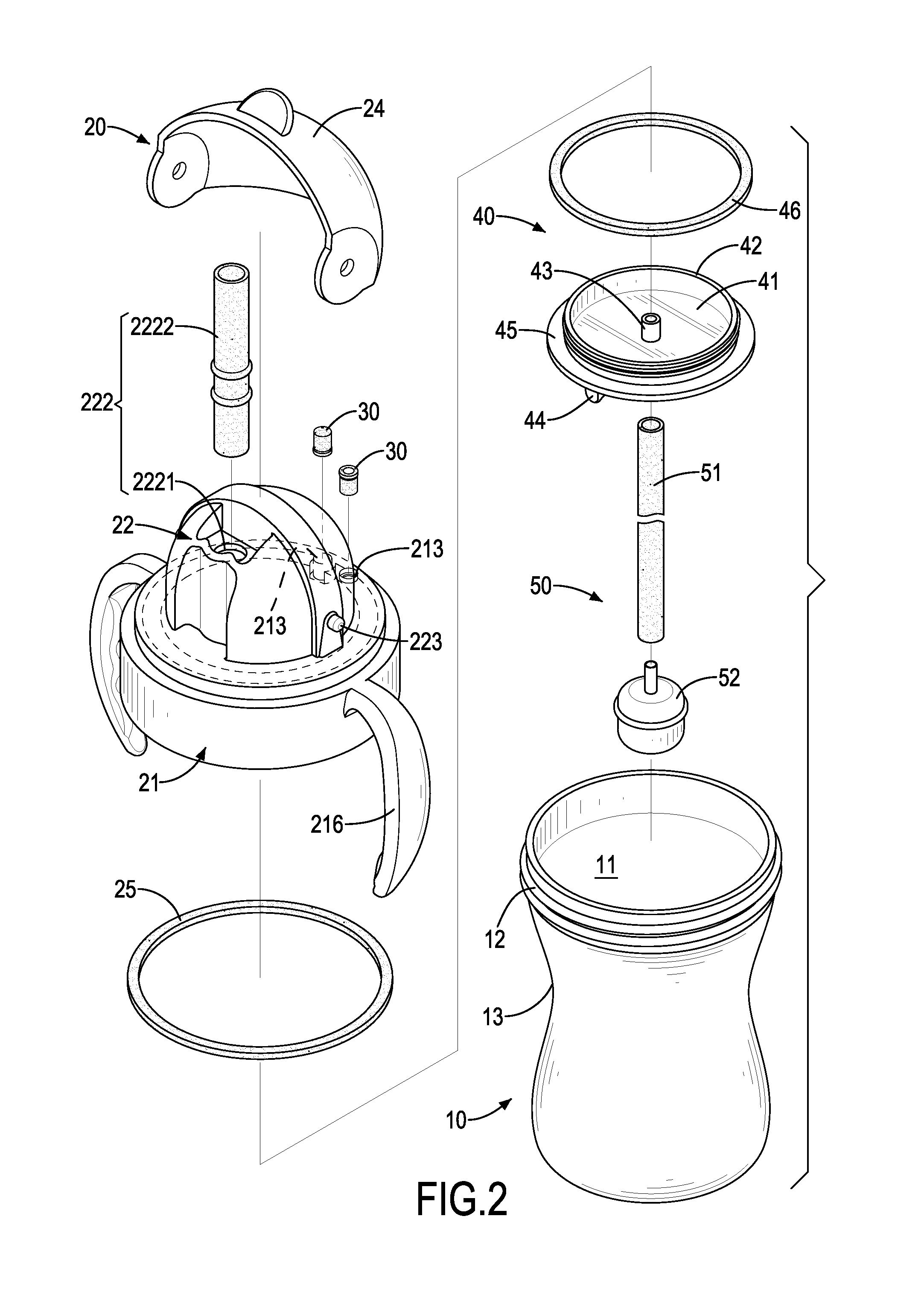

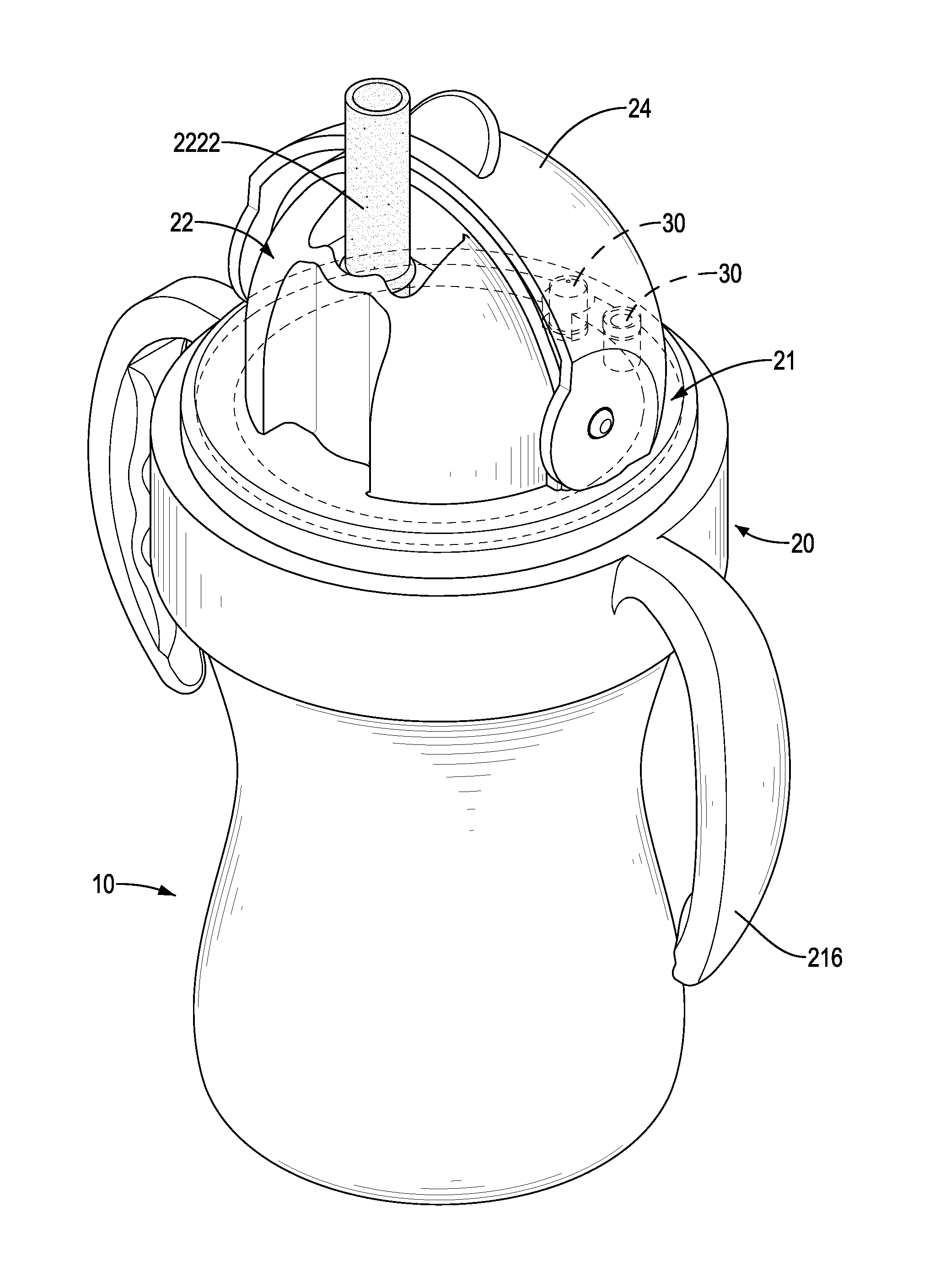

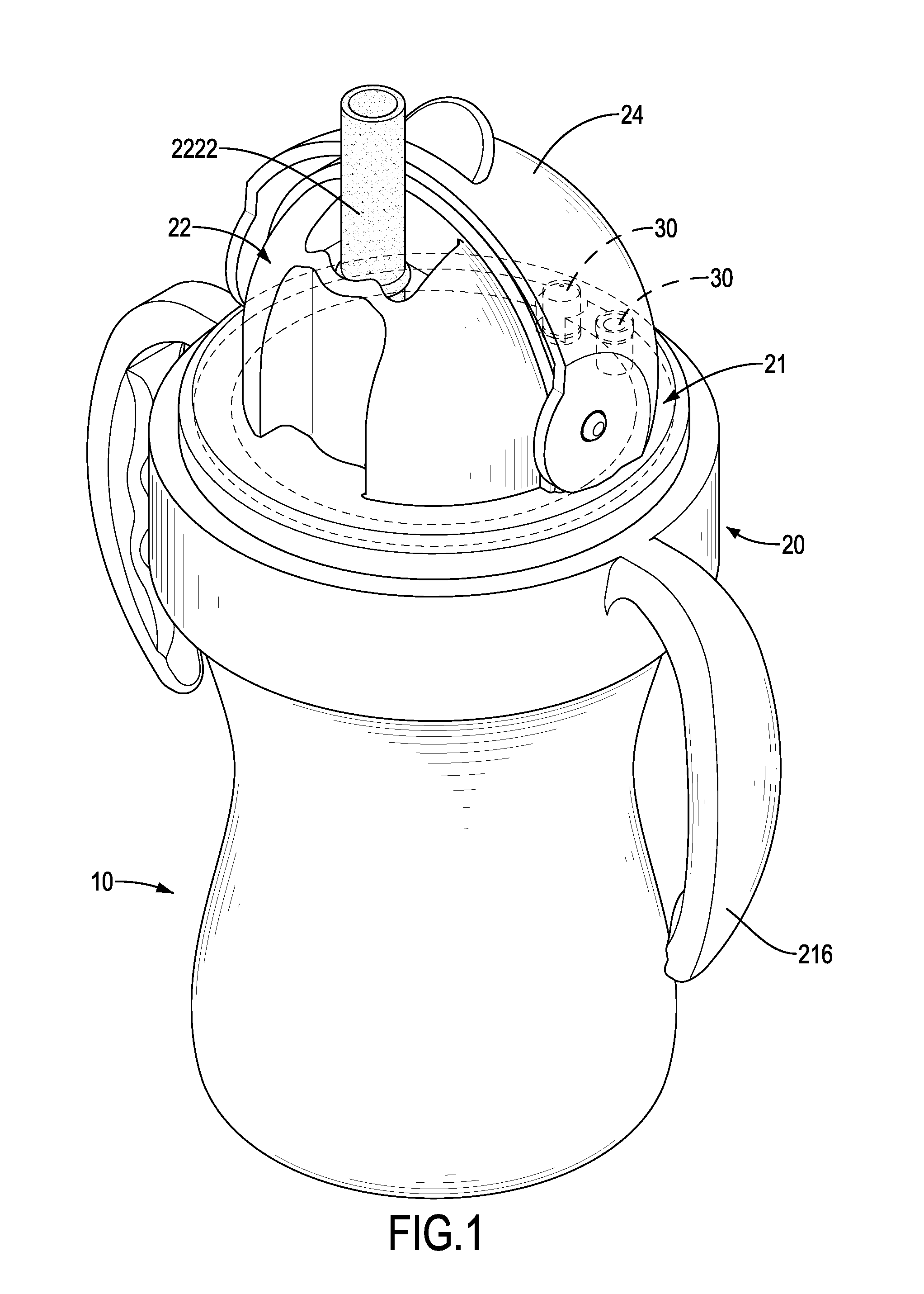

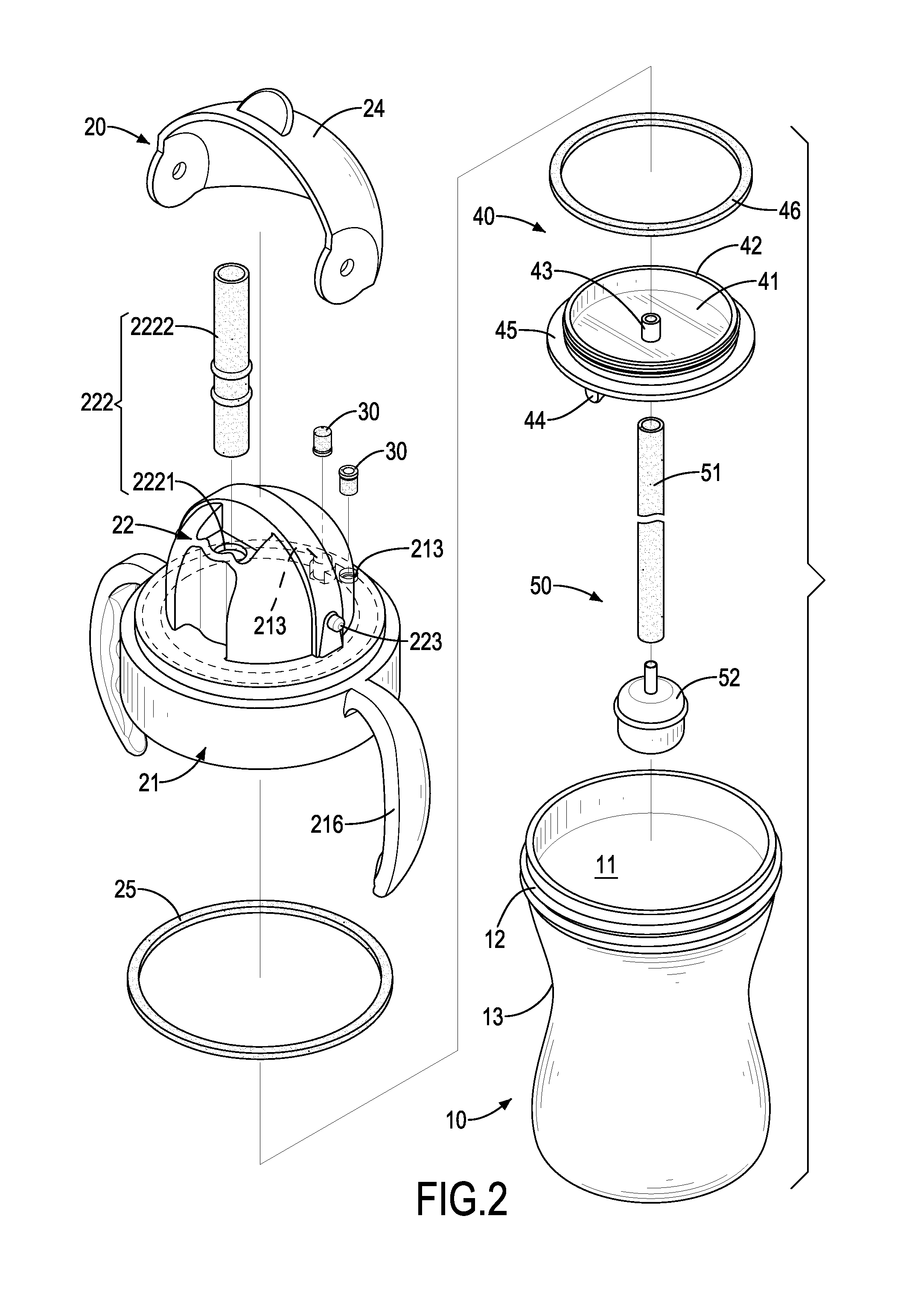

Anti-spray drinking bottle

An anti-spray drinking bottle has a body, a lid, at least one check valve, a dividing mount and a guiding element. The body has a storage recess and a screwing section. The lid is detachably connected to the body and has a threaded segment connected to the screwing section, a buffering segment connected to the threaded segment and a buffering space formed in the buffering segment. The at least one check valve is mounted on the lid. The dividing board is connected to the lid, is mounted in the body and has a dividing board, a sidewall, an outlet pipe and an abutting segment. The guiding element is connected to the dividing mount, is mounted in the body and has an elongate straw tube connected to the outlet pipe.

Owner:LIANG HSIAO CHEN

Optimized detection of fission neutrons using boron coated straw detectors distributed in moderator material

InactiveUS8569710B2Efficient detectionEasy to detectMeasurement with semiconductor devicesDosimetersFission neutronElectrical impulse

The present invention includes an apparatus and method for neutron radiation detection. The apparatus comprises combining thin walled, boron-coated straw tubes with a plastic moderator material interspersed around the tubes. The method involves using such an apparatus through application of voltage to a central wire running inside the tubes and collecting electrical pulses generated thereby.

Owner:PROPORTIONAL TECH

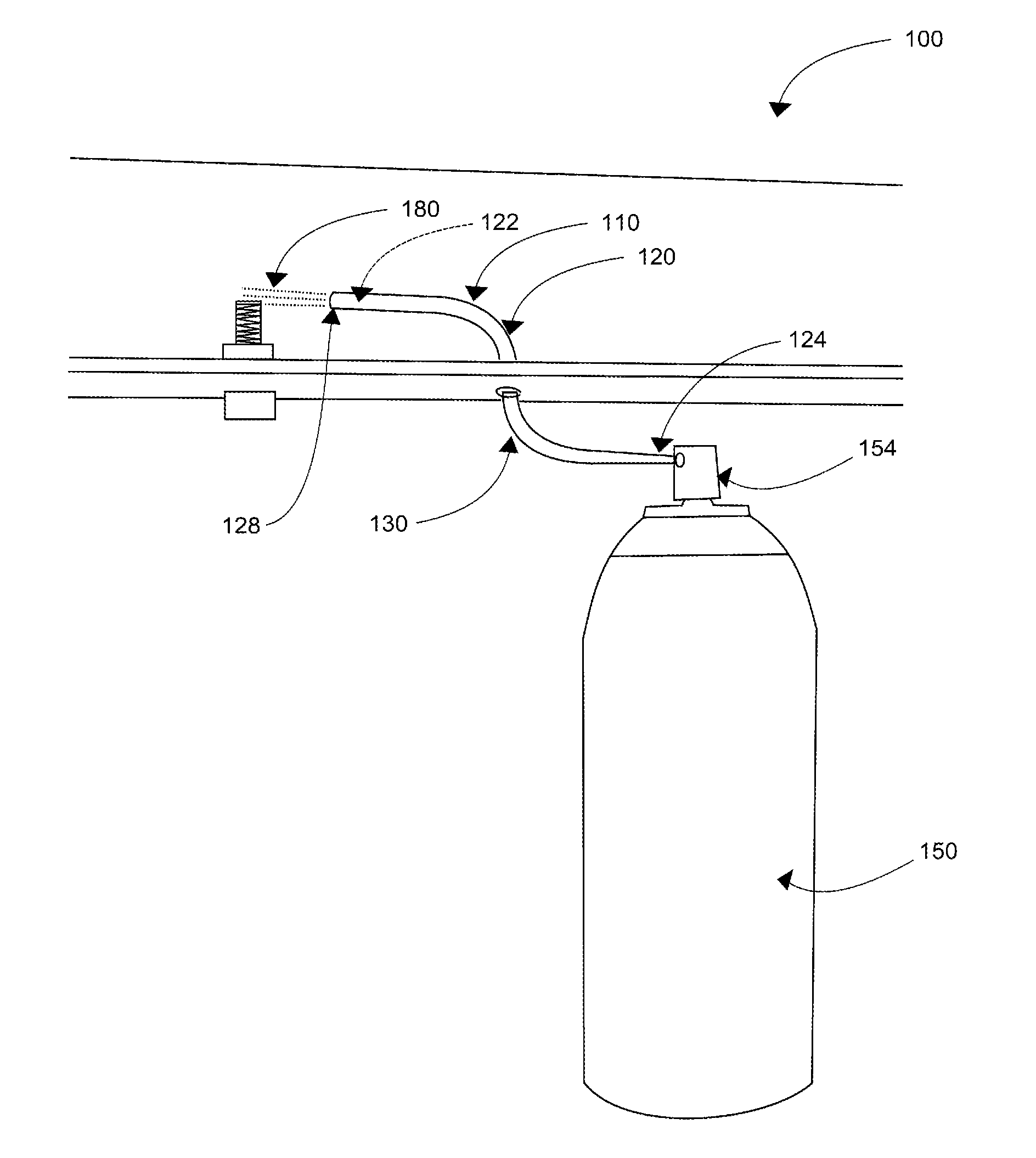

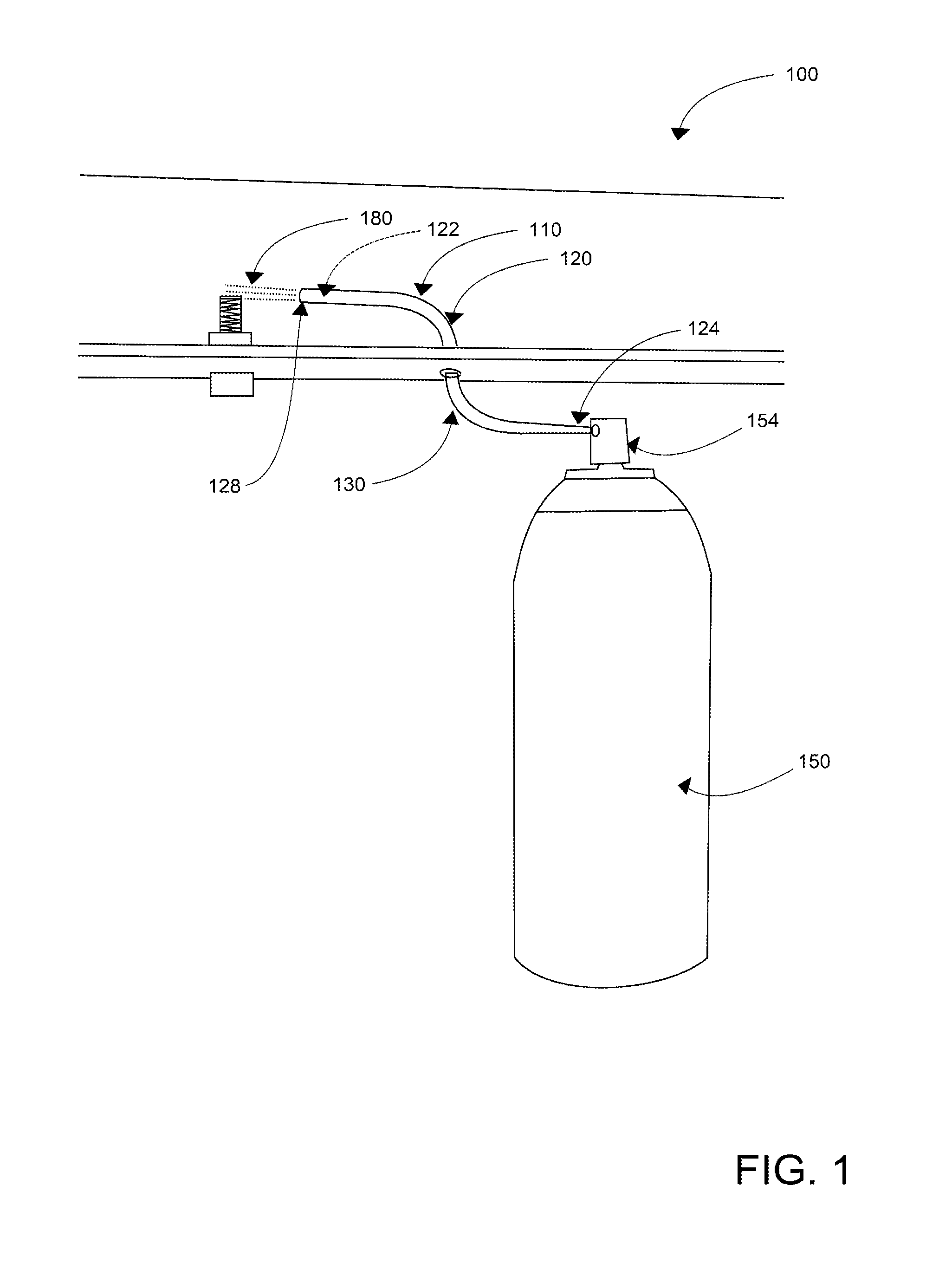

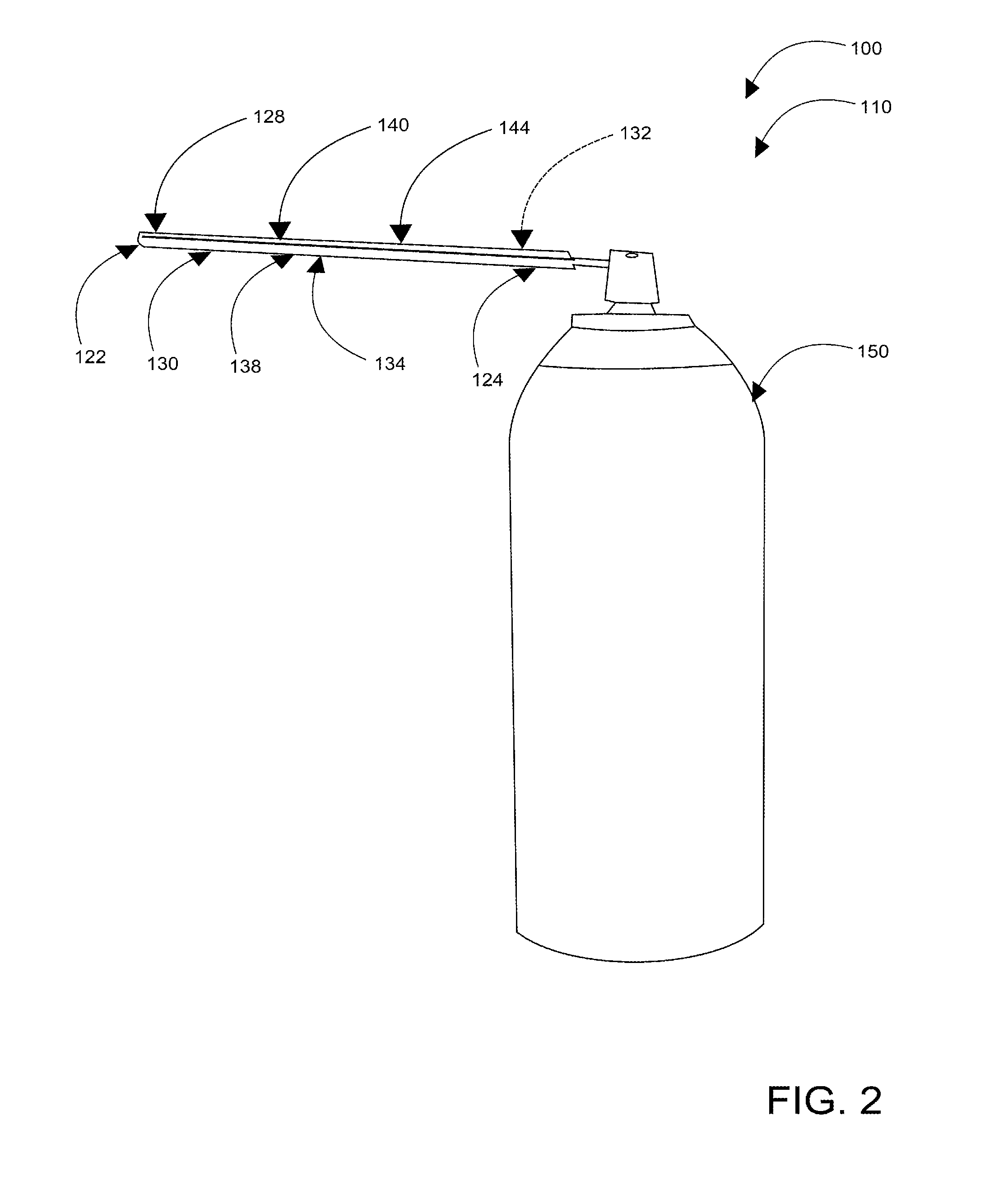

Acu-spray aerosol straw systems

InactiveUS20120000930A1Efficient and effective dispensingPrecise positioningOpening closed containersBottle/container closureRigid structureUser defined

Acu-Spray Aerosol Straw is designed to allow the contents of a pressurized container to be dispensed at virtually any angle. Acu-Spray Aerosol Straw comprises a bendable, plastic straw. A wire is molded into the sidewall of the straw or molded integral to the straw tube as supporting means. The wire may be housed in a plastic casing and then molded onto the side of the original aerosol straw. The molding together of the wire that is encased and the straw-tube effectively prevents the separation of the two components due to bending. The bendable straw in combination with the wire is bendably-manipulatable such that a propelled fluid from a pressurized container is strategically dispensed onto a user-defined location. The device may be detachable from the nozzle to prevent breakage while the can is in storage. In certain embodiments the device may comprise a non-wire version wherein the bendable straw may be a non-bendable rigid structure. The rigid straw embodiment may comprise L-shaped, C-shaped, V-shaped configurations and / or other such shapes.

Owner:BARBIERI RICHARD G

Full biodegrade straw sucker and preparation method thereof

The invention discloses a full biodegrade straw sucker and a preparation method thereof, and belongs to the technical field of sucker preparation. A pretreated straw tube is soaked in cellulose solution, taken out and gelated in air to form a cellulose colloidal film on the surface of the straw tube, the straw tube is placed into distilled water to perform solvent exchange, and the straw tube is naturally air-dried to obtain the straw sucker. The straw sucker is connected by a connecting component prepared by 3D (three-dimensional) printing to obtain the full biodegrade straw sucker. The cellulose solution comprises natural cellulose pulp and mixed solvents for dissolving the natural cellulose pulp, wherein the mixed solvents comprise dimethyl sulfoxide, tetrabutyl ammonium hydroxide and water. The sucker is simple in preparation process and safe to use, can be fully degraded and cannot pollute environments.

Owner:SOUTHWEST JIAOTONG UNIV

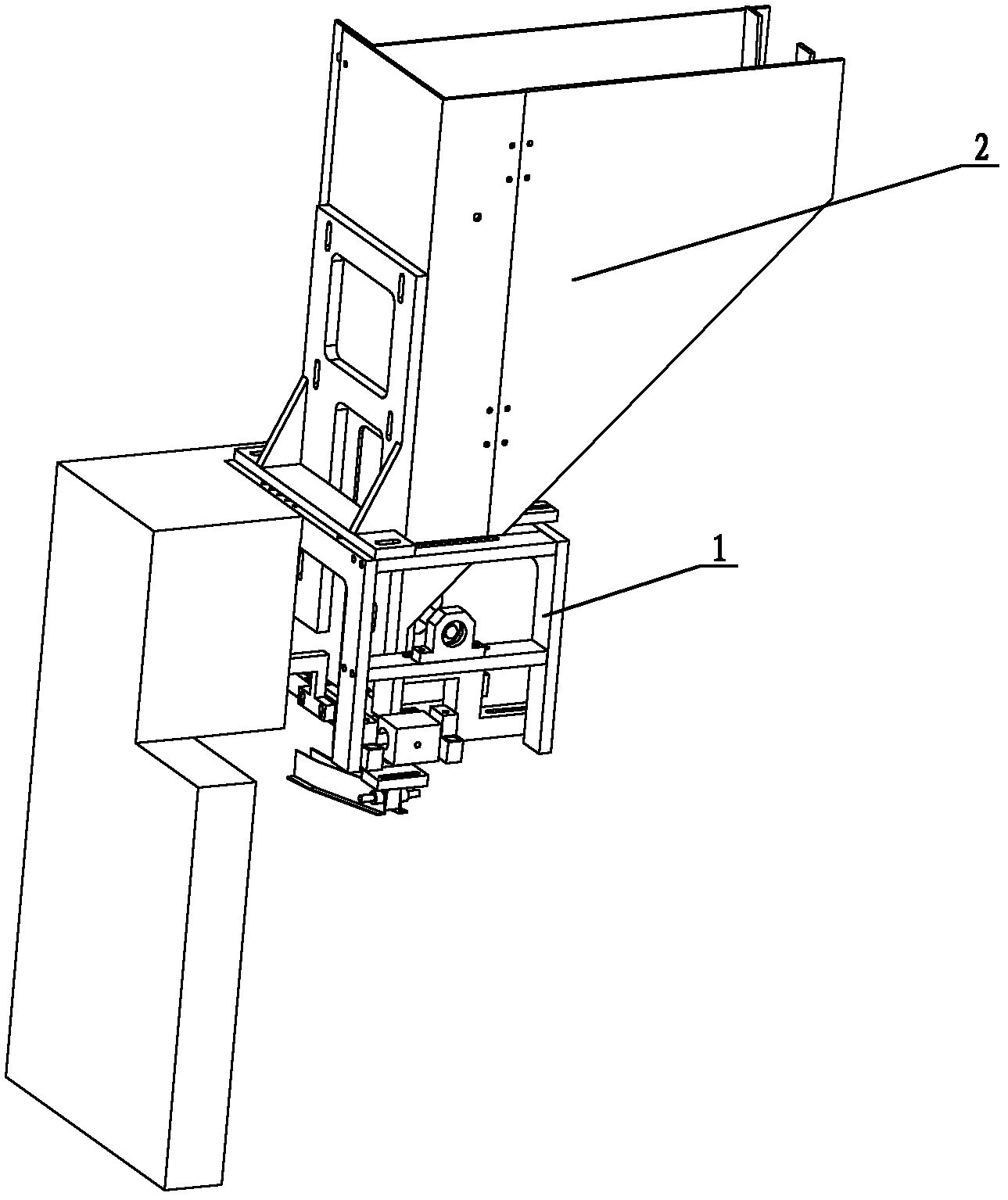

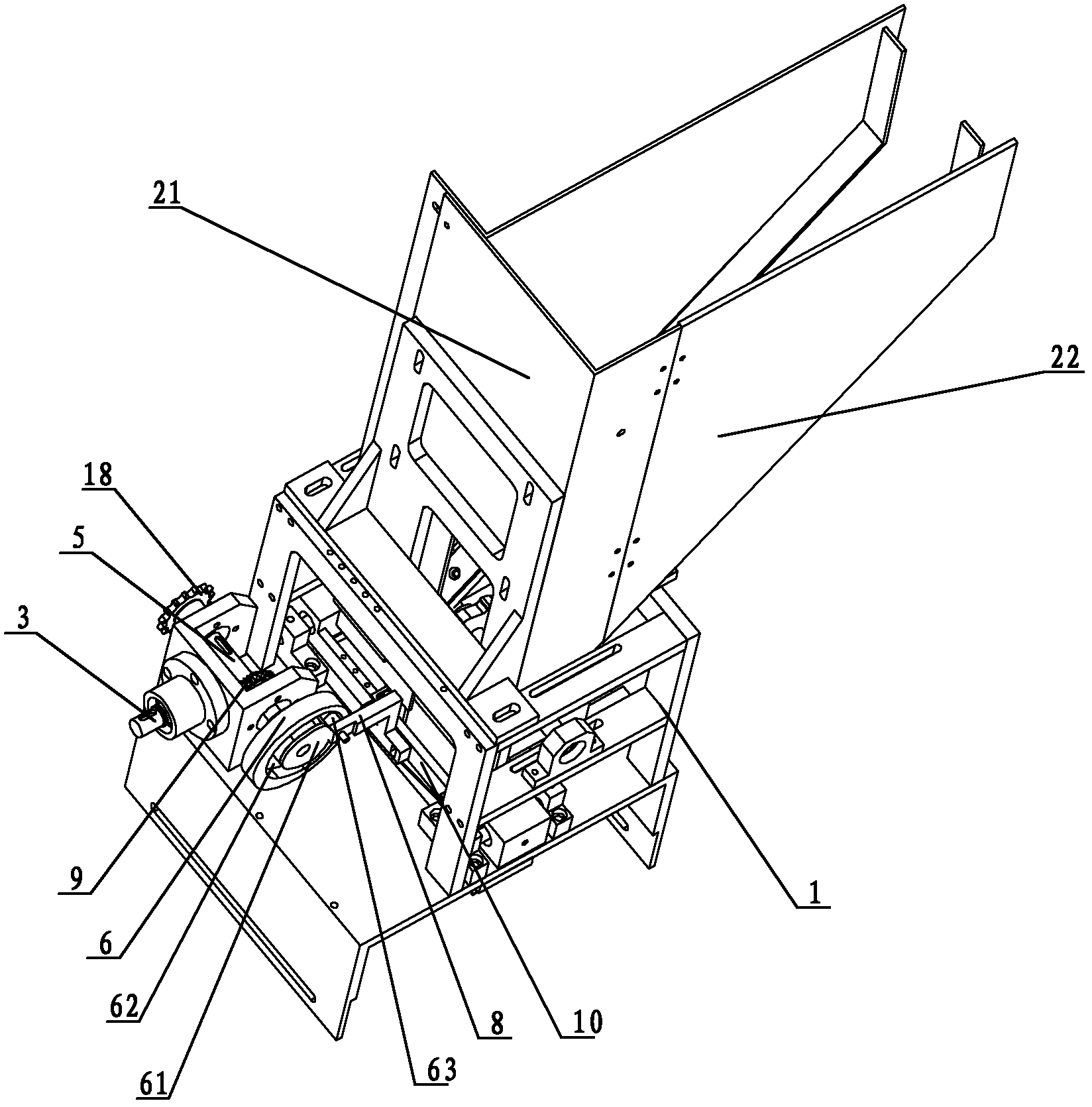

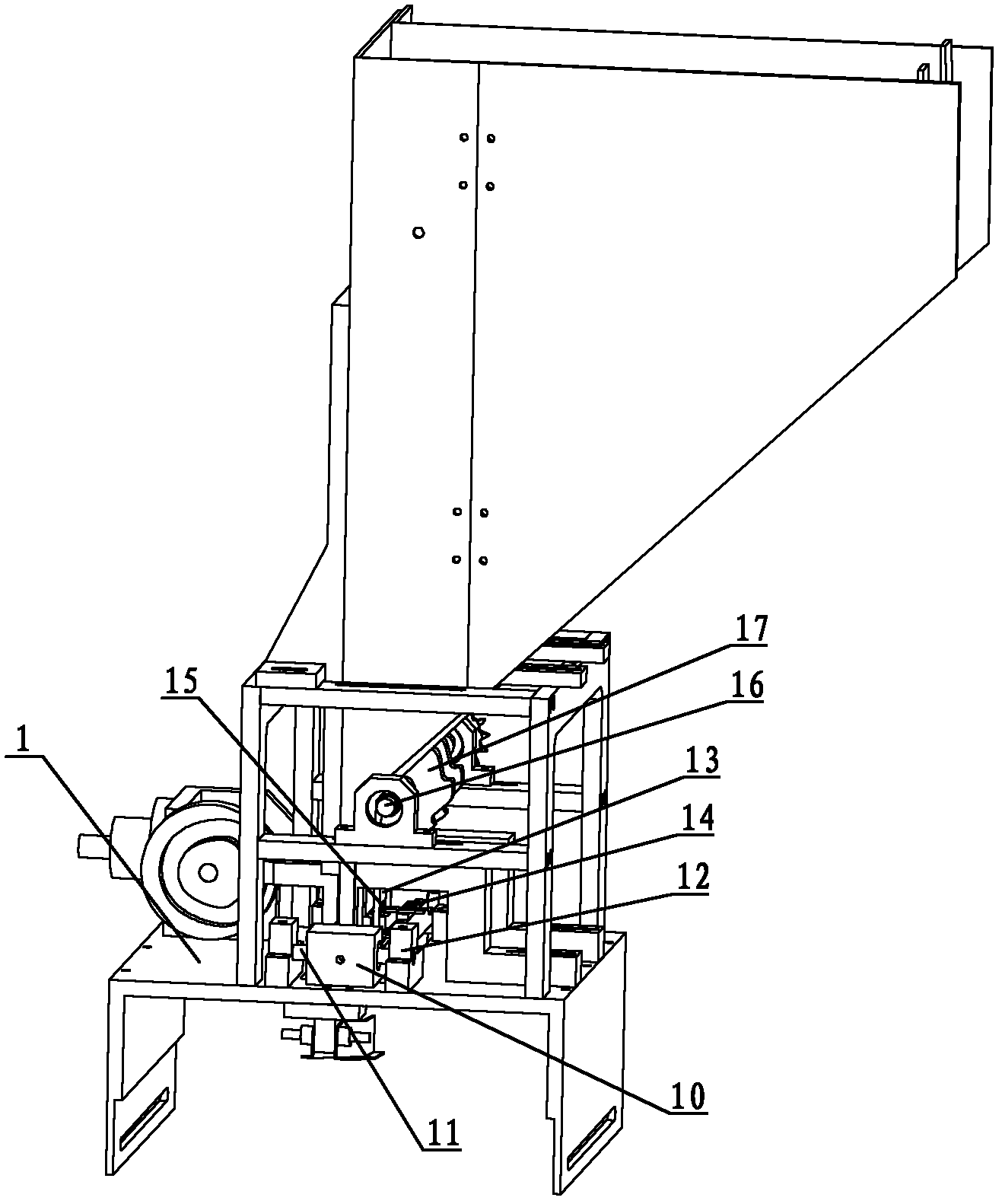

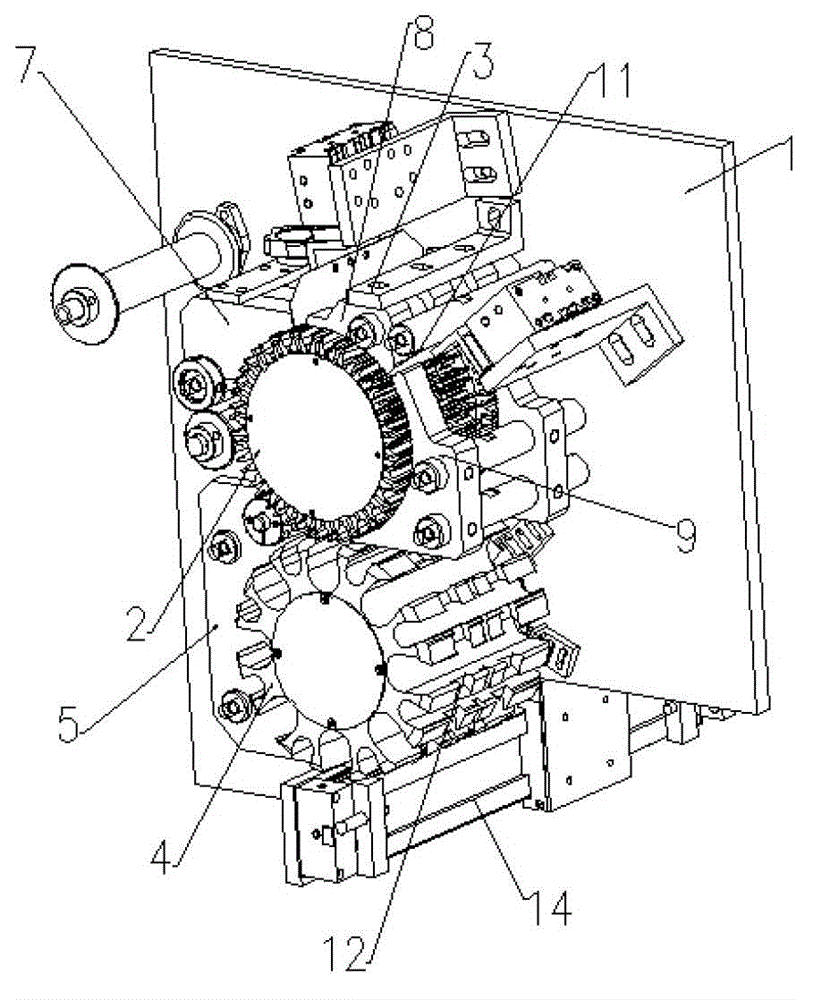

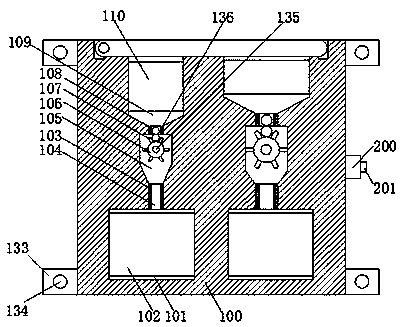

Feeder for straws

The invention relates to a feeder for straws, which mainly solves the problems of poor reliability, short service life, inaccuracy in arrangement of straw materials and poor feeding efficiency of an existing feeder for straws. A transmission mechanism of the feeder comprises a first transmission shaft, a rotary disk, a bearing and a push rod, the first transmission shaft is in transmission match with a driving shaft through a conical gear and is connected with the rotary disk, the rotary disk is provided with a 'cam-shaped' groove, a cam matched with the shape of the groove is arranged in the middle of the groove, a cam rail is formed between the outer wall of the groove and the outer surface of the cam, and the push rod is connected with the bearing arranged in the cam rail and is matched with a feeding mechanism. By adopting a cam mechanism to drive the feeding mechanism to move and realize feeding, the feeder is low in noise, stable and reliable in process and long in service life.

Owner:瑞安市金泰包装机械有限公司

Suction and release double paper mechanism of sticky handle paper cup forming machine

ActiveCN103317776BSolve the problem of hot handsReduce cost burdenPaper/cardboard articlesCost burdenPulp and paper industry

A double paper piece absorbing and releasing mechanism for a pasted handle type paper cup forming machine comprises an absorbing and releasing structure and a stacking structure. A cam rocker drive mechanism is connected with a connecting rod to form the absorbing and releasing structure, the connecting rod is movably connected upwards with a sliding plate, rollers and pins, the sliding plate is sequentially connected upwards with a pipe seat, suction pipes and suction nozzles, and a paper frame plate is arranged above the suction nozzles. The stacking structure mainly comprises the paper frame plate, a paper frame strip, a support leg, a blowing seat, a blowing pipe, a horizontal shaft, a support rod, a frame leg, paper stoppers, paper blocking rods and the like. The paper blocking rods are arranged on the peripheries of a front opening and a rear opening of the paper frame plate, and each paper blocking rod is used for blocking double paper pieces. The double paper piece absorbing and releasing mechanism has the advantages that the double paper pieces are stacked by the aid of a single paper frame, a single cam rocker drives two groups of suction nozzles to move, a paper cup with a handle can be produced once, the problem that the paper cup is too hot to handle is solved, and the cost burden of secondary manufacture is relieved.

Owner:瑞安市胜利机械有限公司

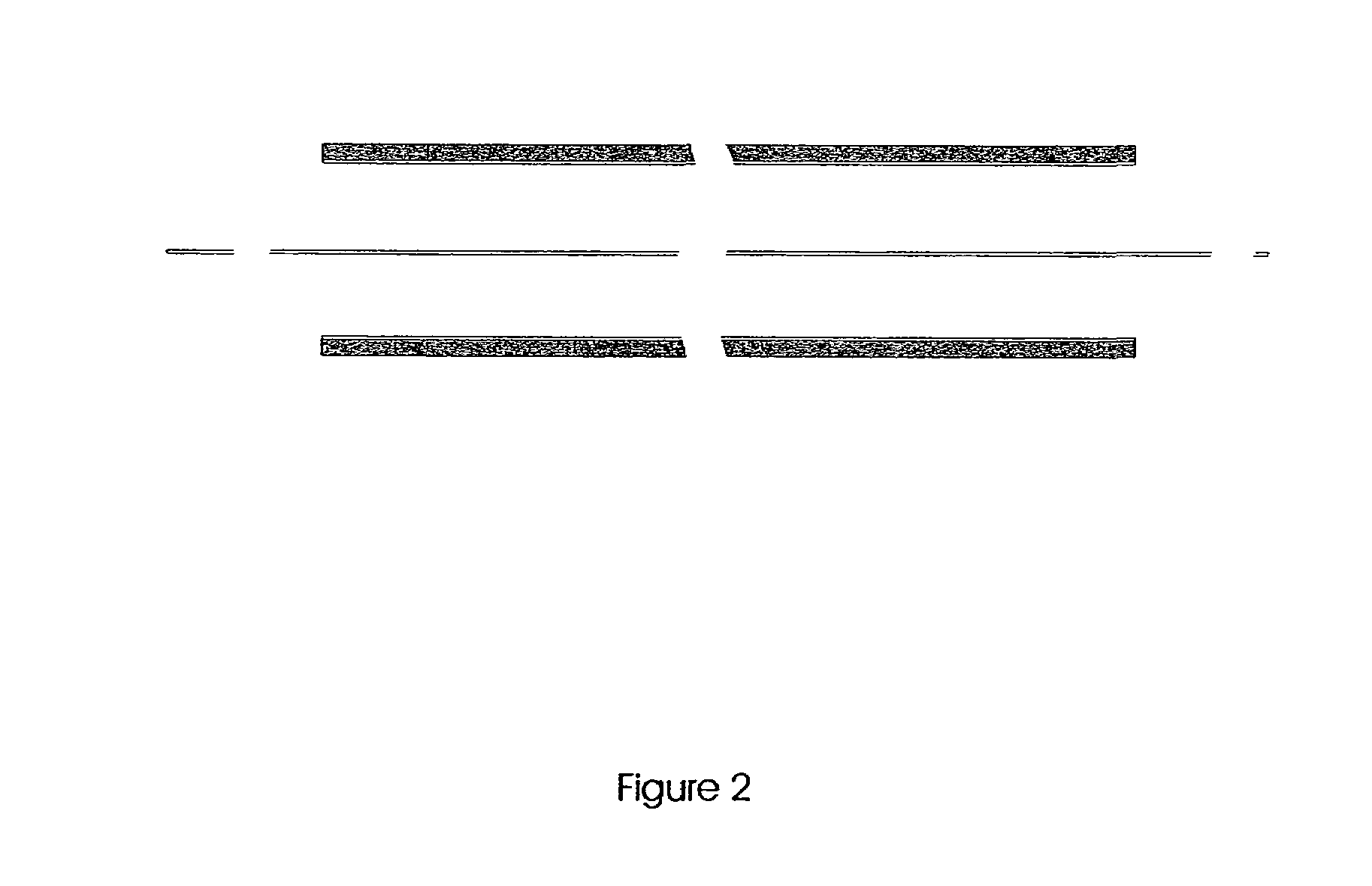

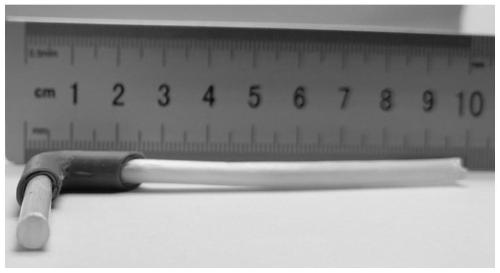

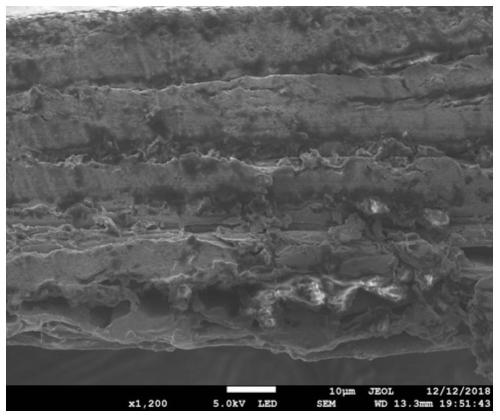

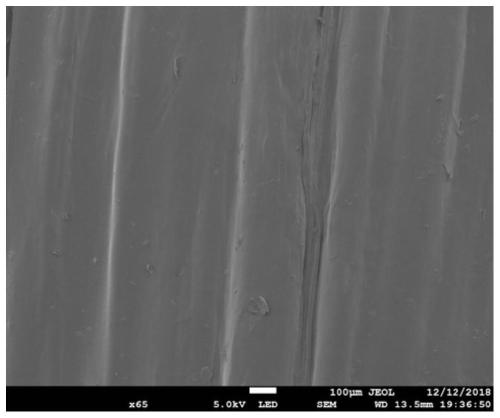

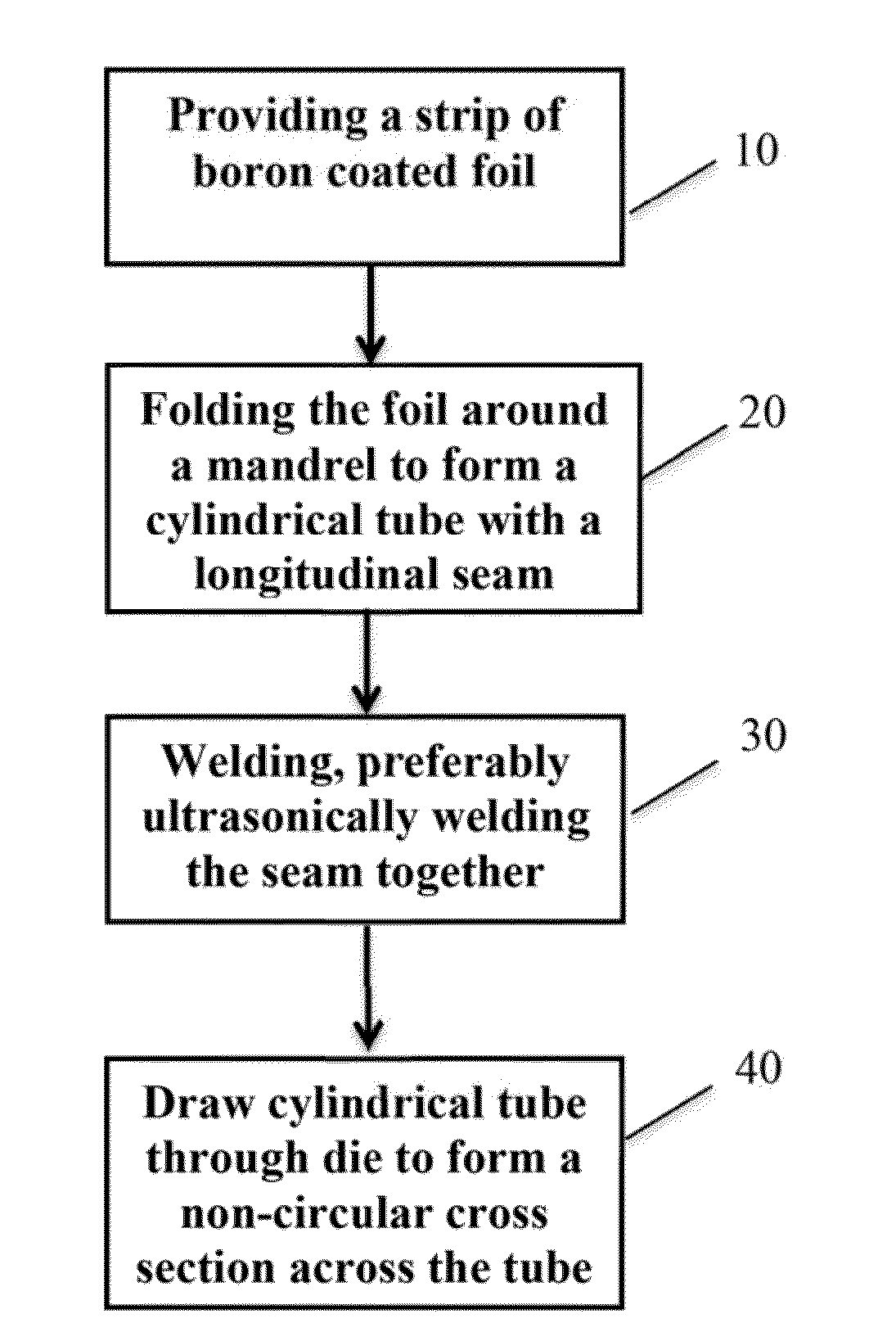

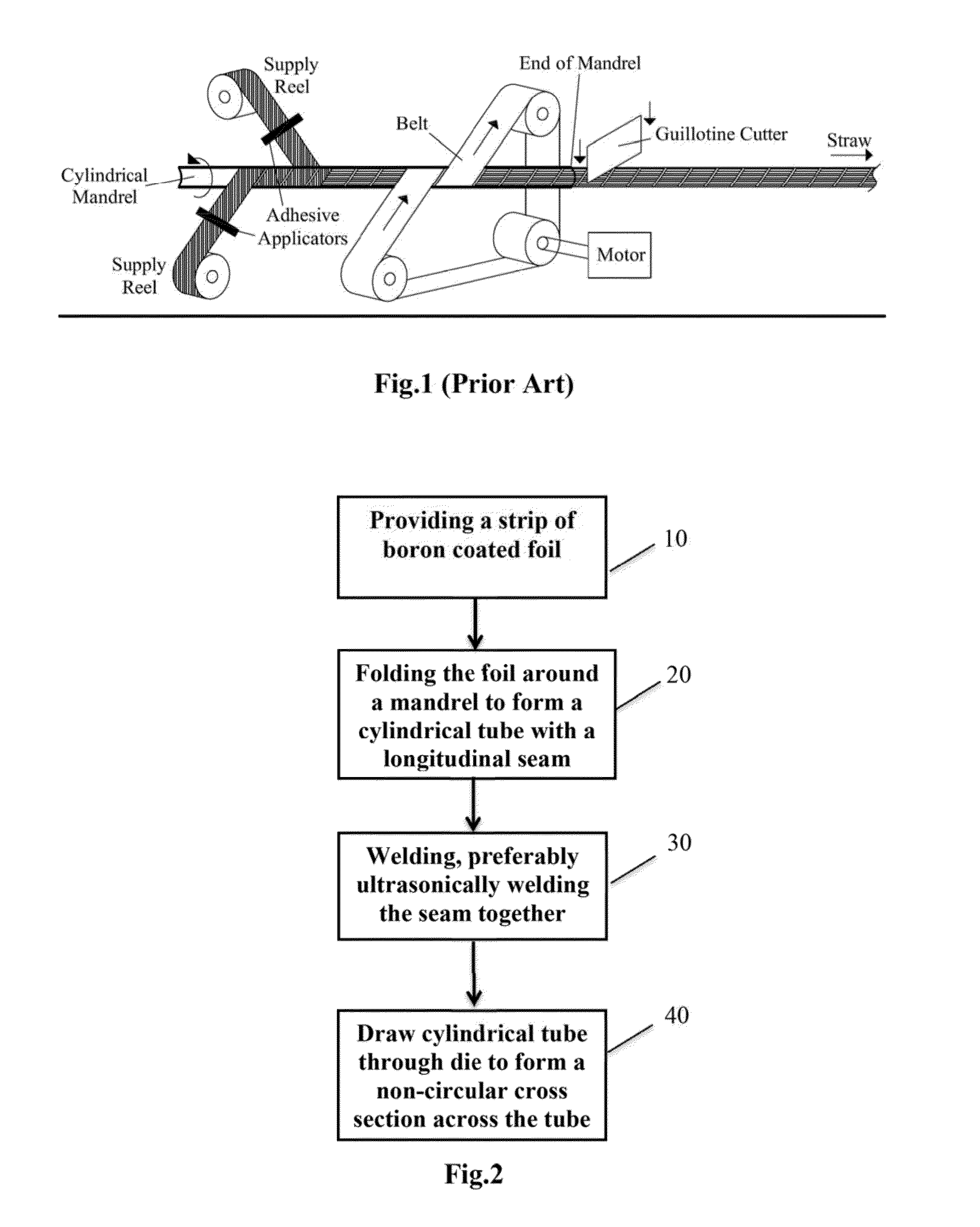

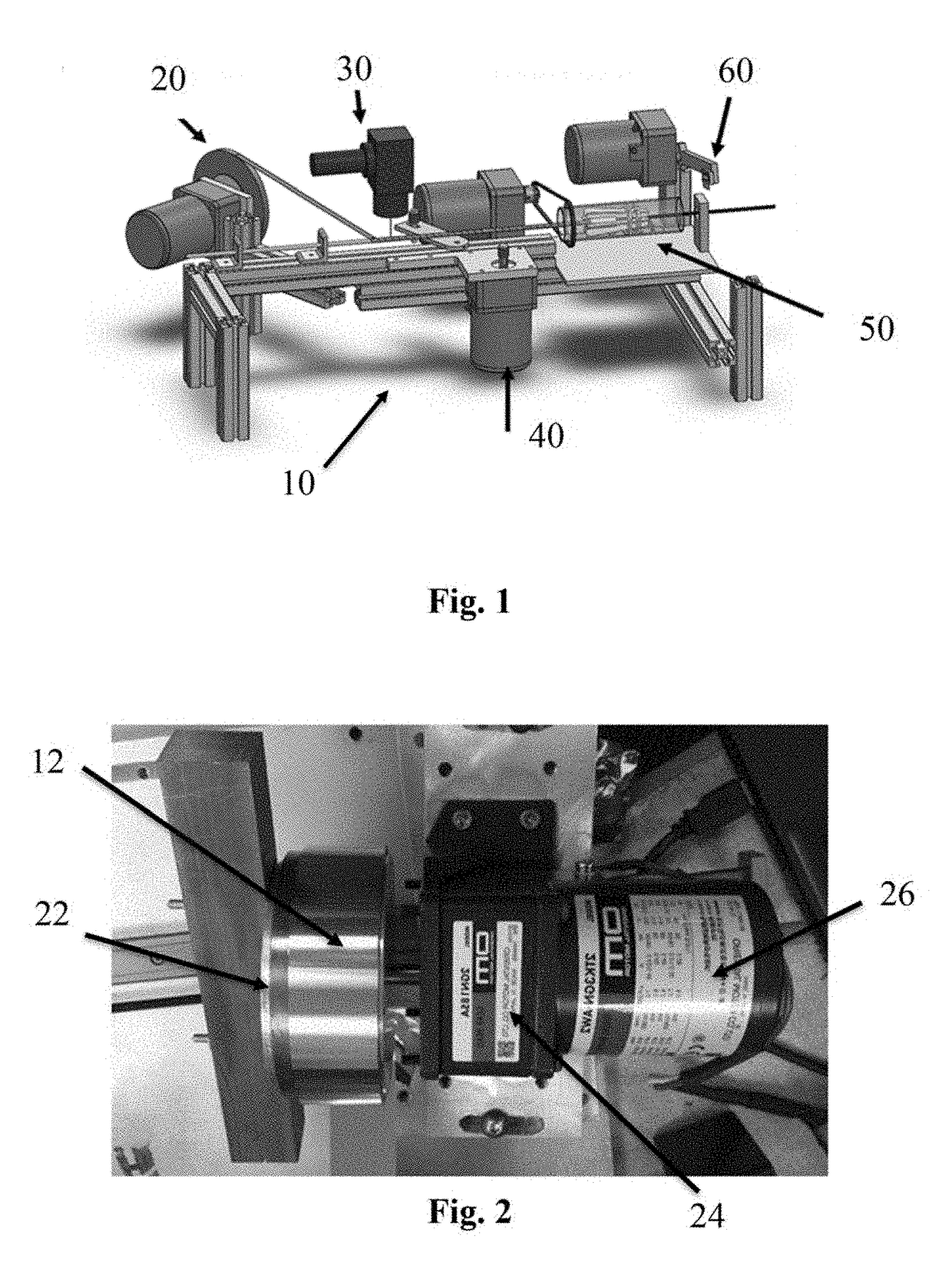

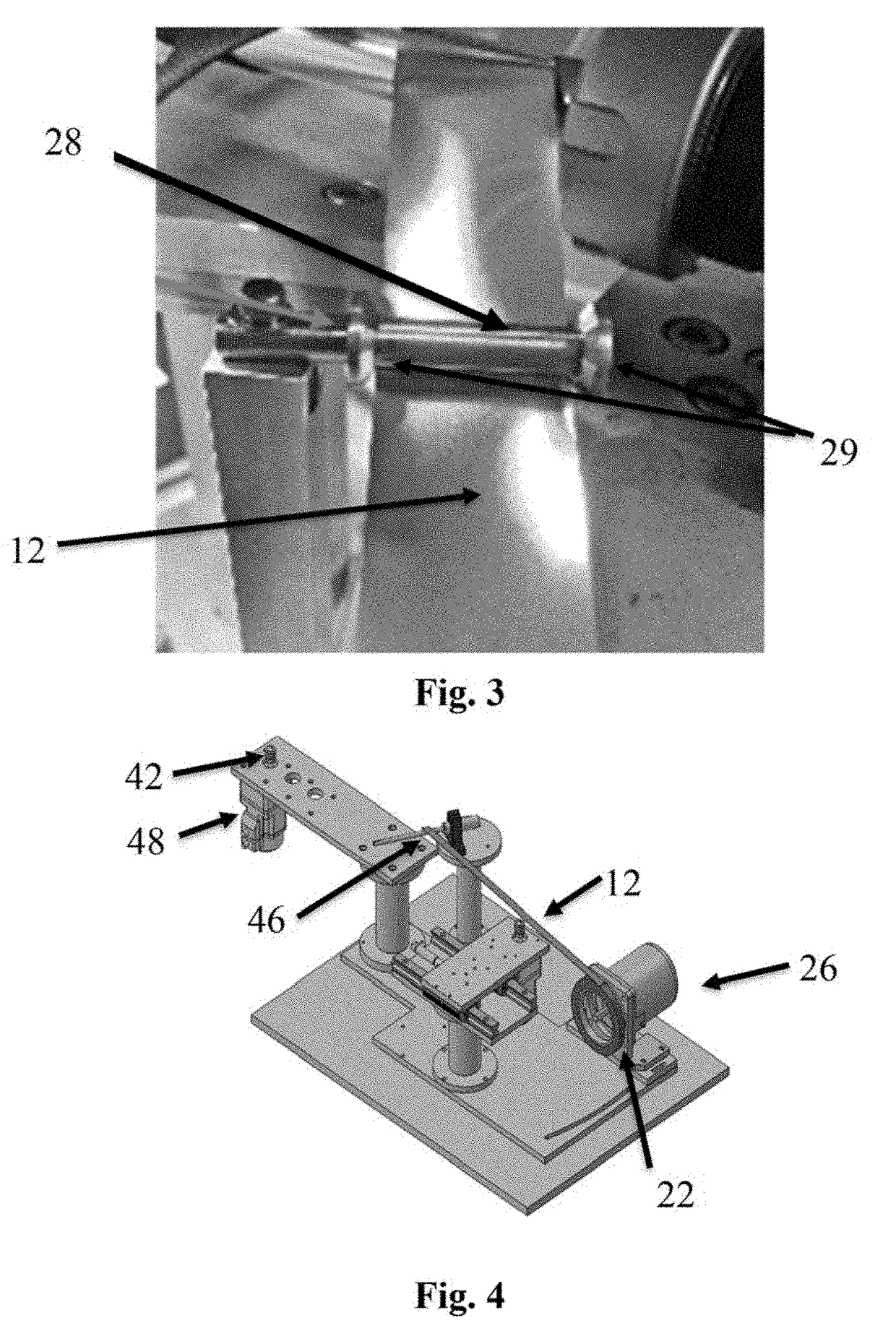

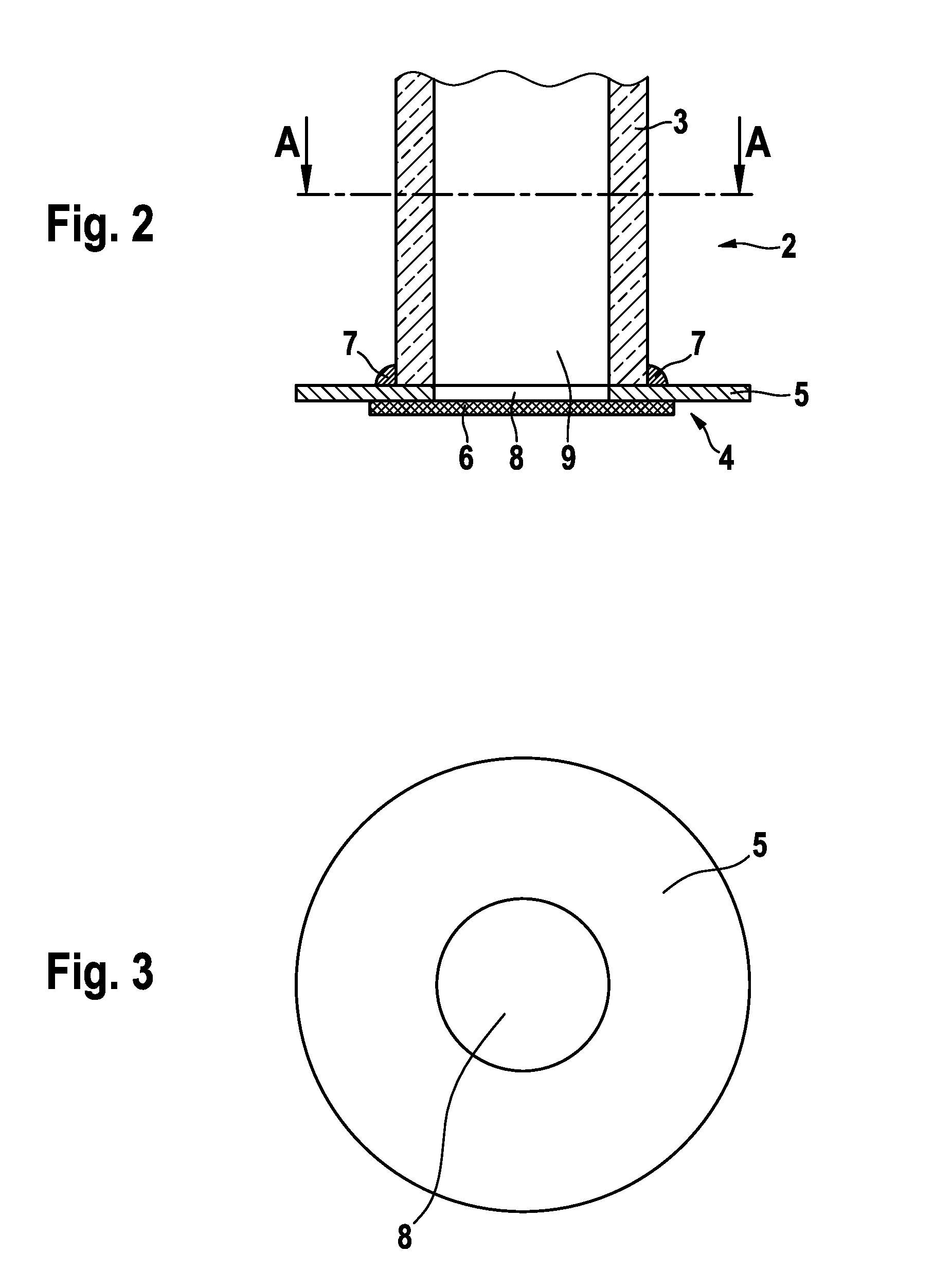

Method and Apparatus for Fabricating Boron Coated Straws for Neutron Detectors

InactiveUS20140110593A1Limit its operationWelding/cutting auxillary devicesVacuum evaporation coatingCoated surfaceMetallurgy

An apparatus and a process are disclosed for straw tube formation utilized in manufacturing boron coated straw neutron detectors. A preferred embodiment of the process for creating a thin walled straw for use in a boron-coated straw neutron detector comprises providing foil having a boron coating on a surface, forming the coated foil into a cylindrical tube having a longitudinal seam and the boron coated surface on the inside of the cylindrical tube, and then ultrasonically welding closed the seam of the tube. Optionally, the cylindrical tube can then be drawn through a die to form a straw tube having a non-circular cross section, preferably a star-shaped cross section.

Owner:PROPORTIONAL TECH

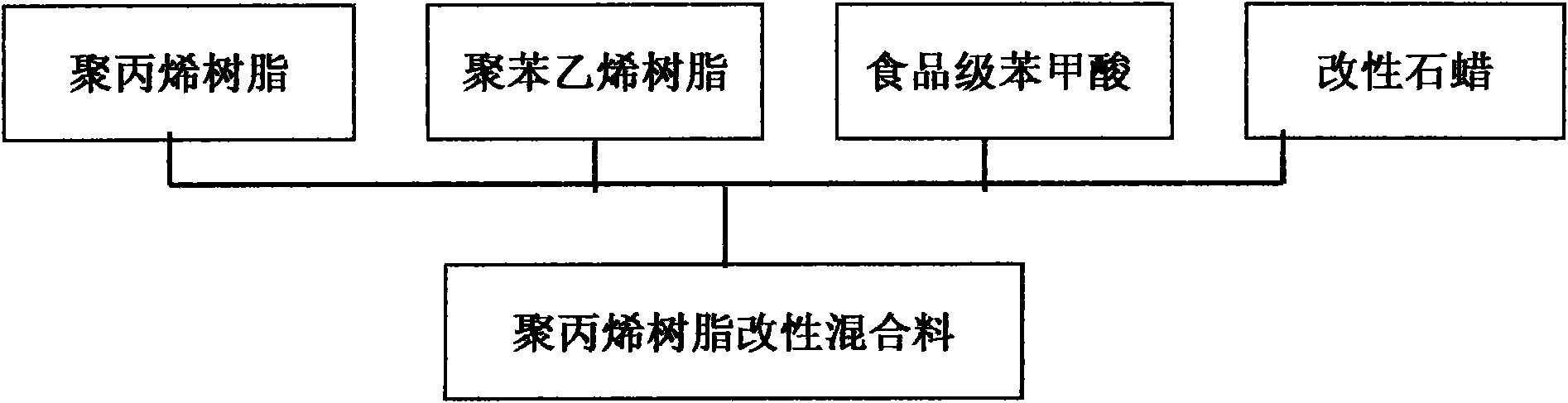

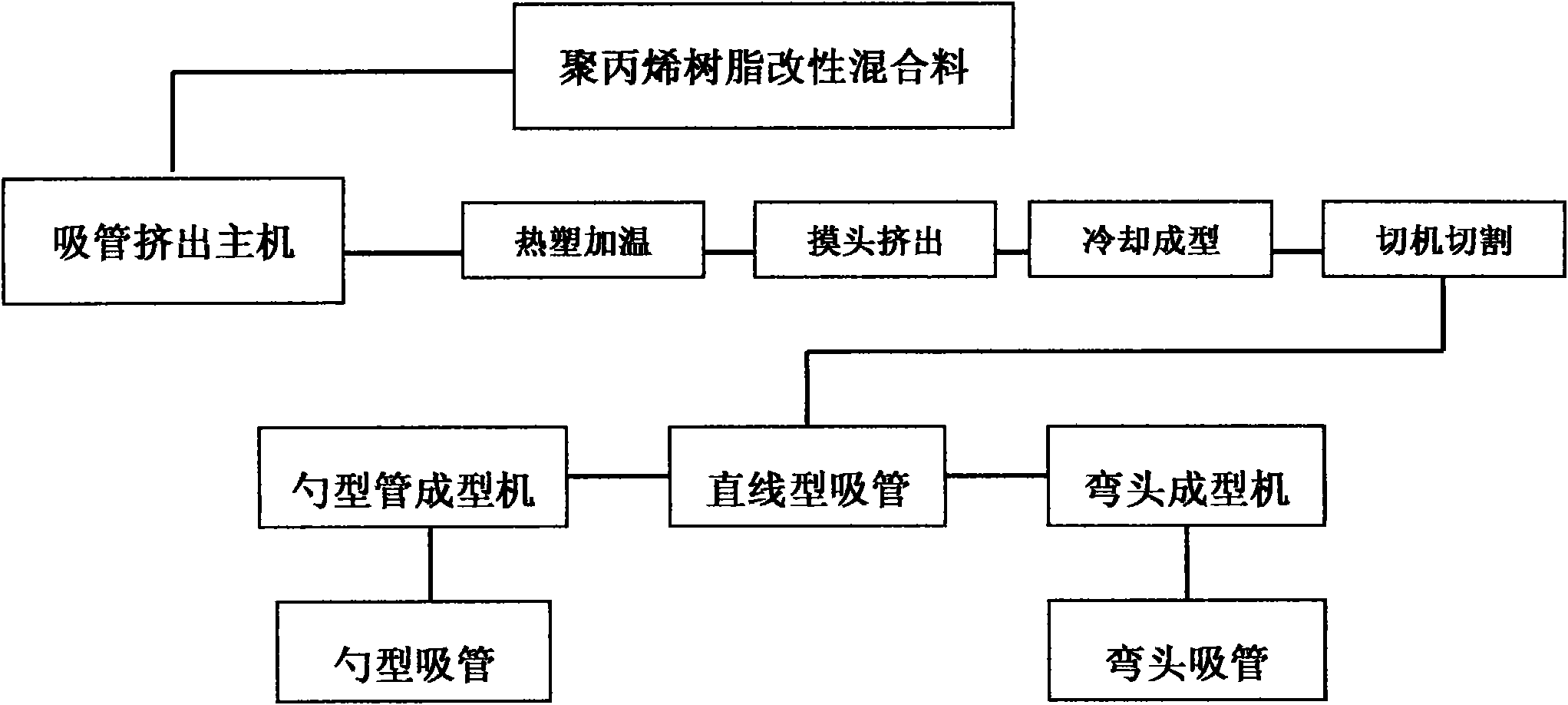

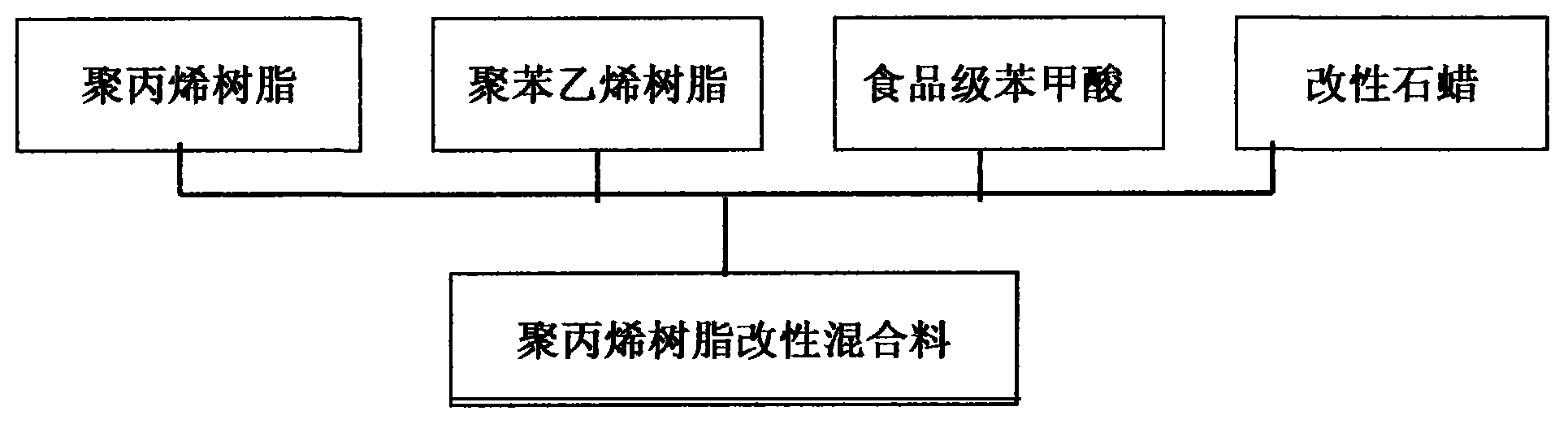

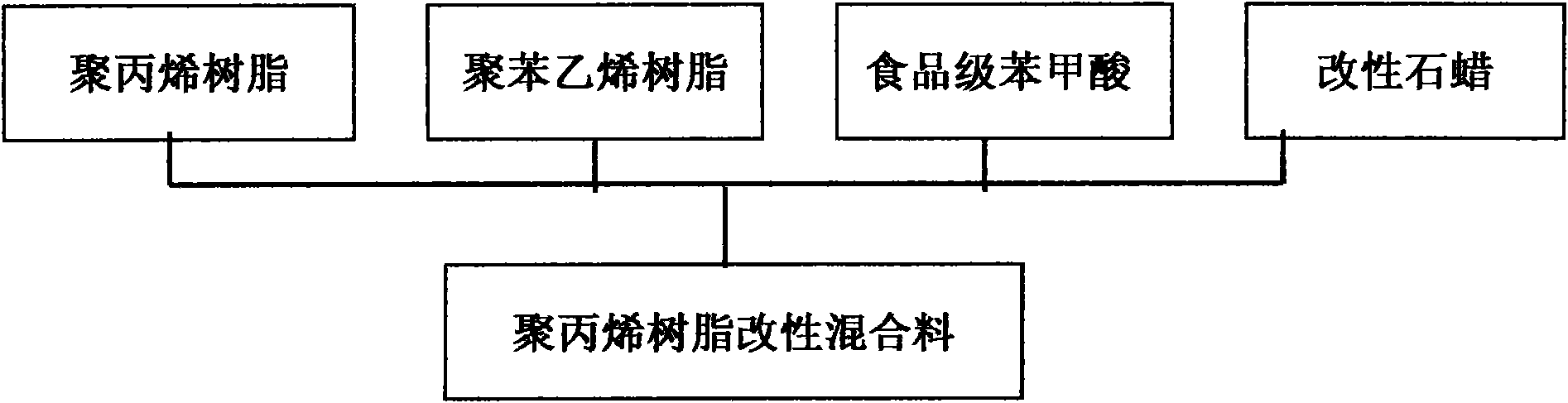

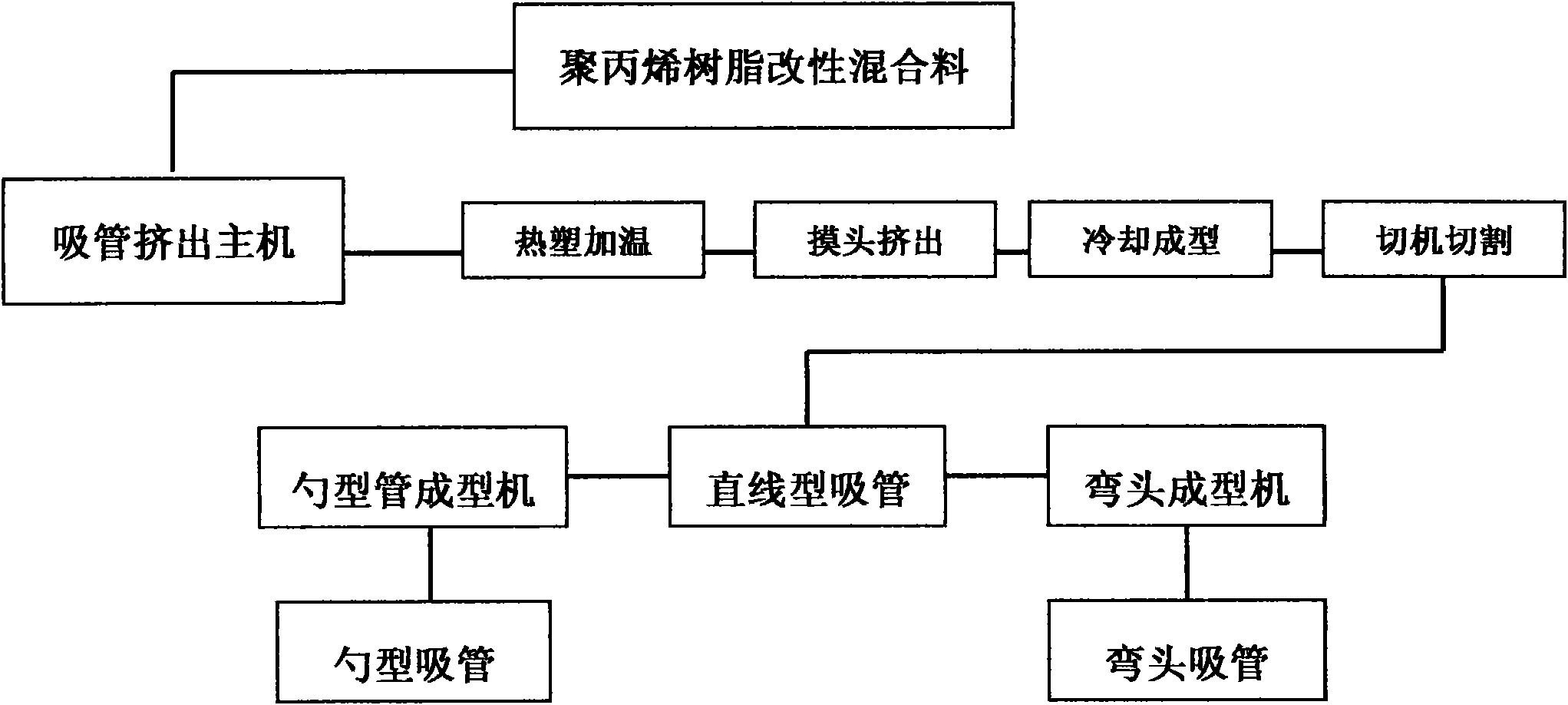

Preparation method of high transparent degradable material and suction tube

ActiveCN102070828AImprove and increase transparencyImprove and enhance the finishTubular articlesTablewaresBenzoic acidPolymer science

The invention provides a preparation method of a high transparent degradable material. The preparation method is characterized by comprising the following steps of: 1) preparing raw materials: based on weight percent, weighing the following raw material components: 95-98 of polypropylene resin, 1-5 of polystyrene resin, 0.01-0.05 of food-grade benzoic acid and 0.1-0.5 of modified paraffin; 2) mixing the components to form a modified polypropylene resin mixing material; and 3) carrying out low-temperature standing on the modified mixing material for later use. The invention also discloses a method for preparing a suction tube by using the above materials. The method for preparing the suction tube comprises the following steps of: 4) preparing a suction tube extruding main machine and a round die head matched with the main machine; 5) feeding the modified mixing material in the extruding main machine to obtain a continuous round hollow suction tube; and 6) cutting the prepared continuous linear type suction tube to suction tube sections. The invention further provides the suction tube prepared by the method. The material provided by the invention is highly transparent and degradable, the method is scientific and reasonable, the production efficiency is high, the product property is good, and the cost is low.

Owner:义乌市双童日用品有限公司

Anti-spray drinking bottle

An anti-spray drinking bottle has a body, a lid, at least one check valve, a dividing mount and a guiding element. The body has a storage recess and a screwing section. The lid is detachably connected to the body and has a threaded segment connected to the screwing section, a buffering segment connected to the threaded segment and a buffering space formed in the buffering segment. The at least one check valve is mounted on the lid. The dividing board is connected to the lid, is mounted in the body and has a dividing board, a sidewall, an outlet pipe and an abutting segment. The guiding element is connected to the dividing mount, is mounted in the body and has an elongate straw tube connected to the outlet pipe.

Owner:LIANG HSIAO CHEN

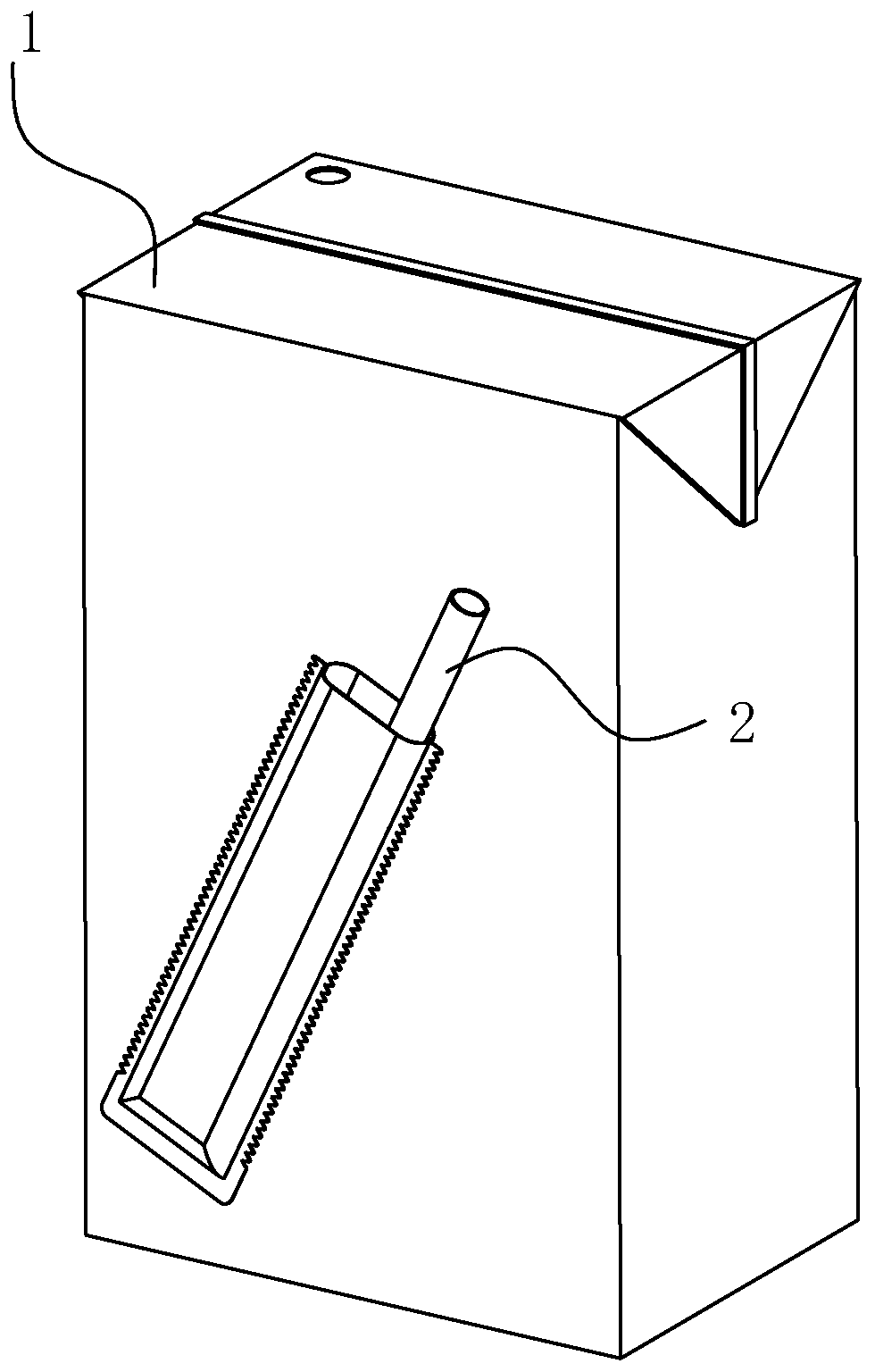

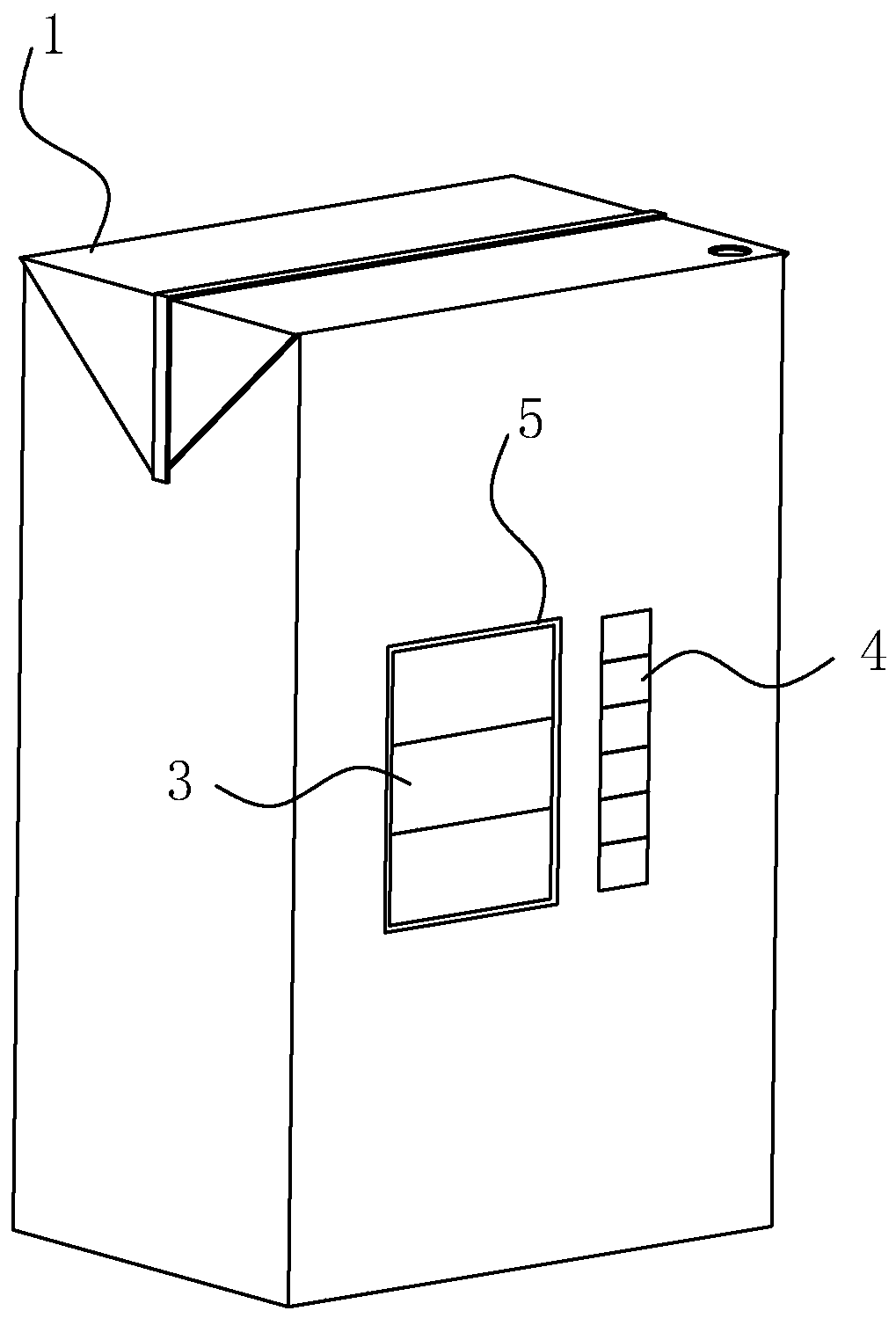

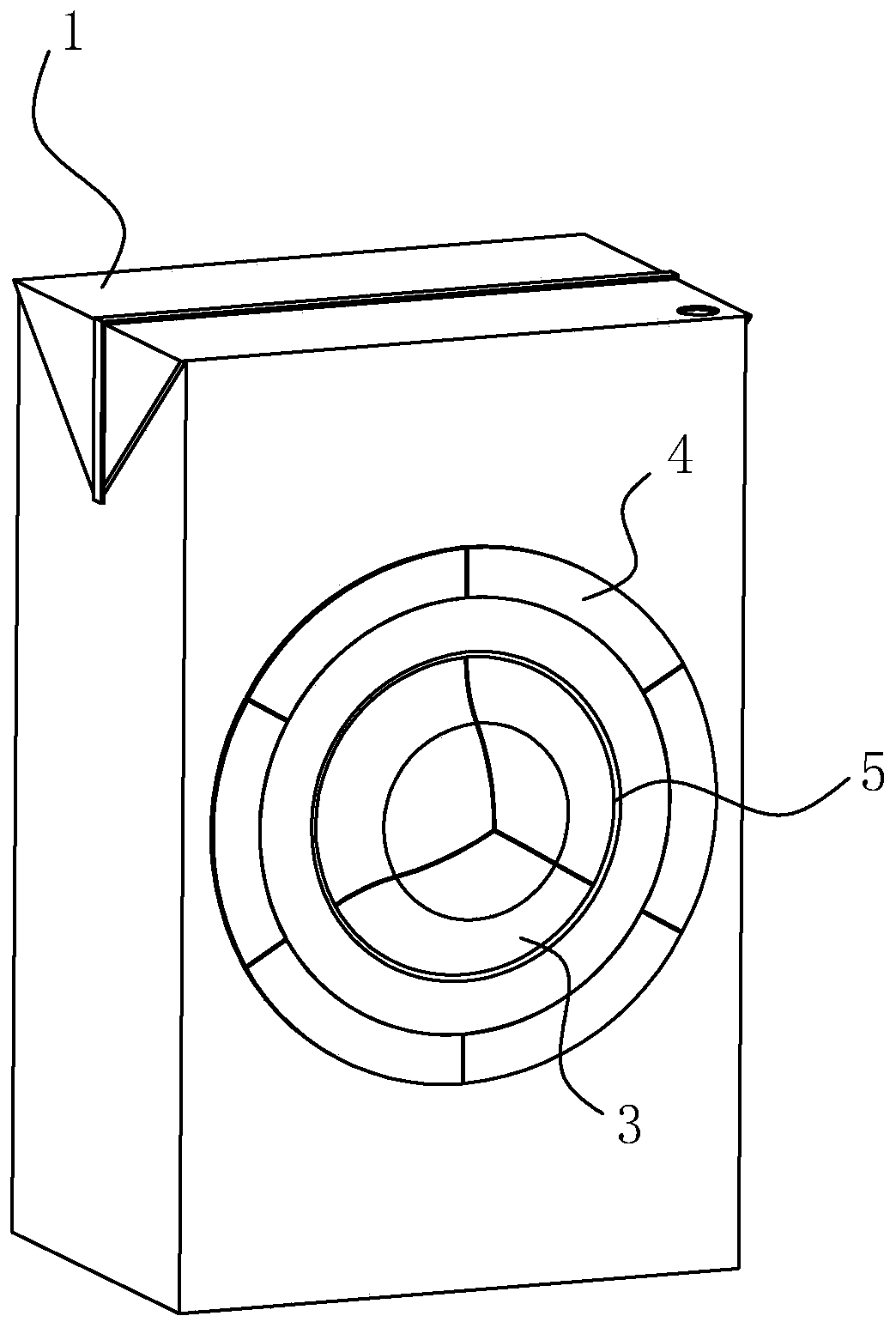

Milk carton

InactiveCN110127203AEasy sales choiceAccurately reflect the temperaturePackaging milkExternal fittingsCartonEngineering

The invention discloses a milk carton, and relates to the technical field of milk packing. The milk carton comprises a carton body and a straw glued to the side surface of the carton body, a metamorphic indication mechanism is arranged on the carton body, the metamorphic indication mechanism comprises at least three or more color change intervals, the non-reversible-temperature-changing ink with the different temperature intervals are filled into the at least three of color change intervals, and a color control card is printed on the side, located on each color change interval, of the carton body. By arranging the non-reversible-temperature-changing ink and the color control cards, the result of whether the milk is deteriorated can be intuitively and accurately obtained.

Owner:SHANGHAI JIELONG YONGFA PRINTING & PACKING

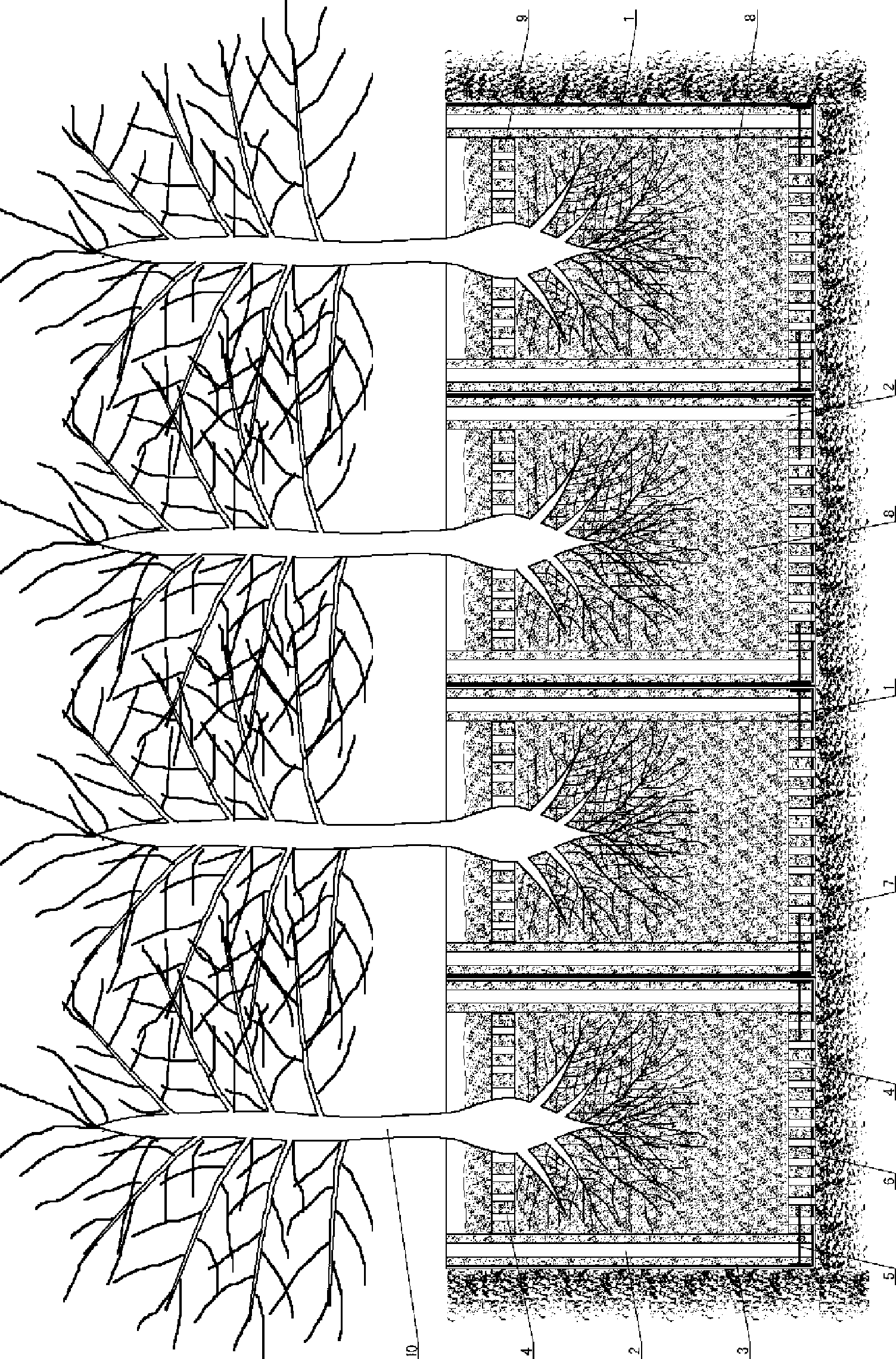

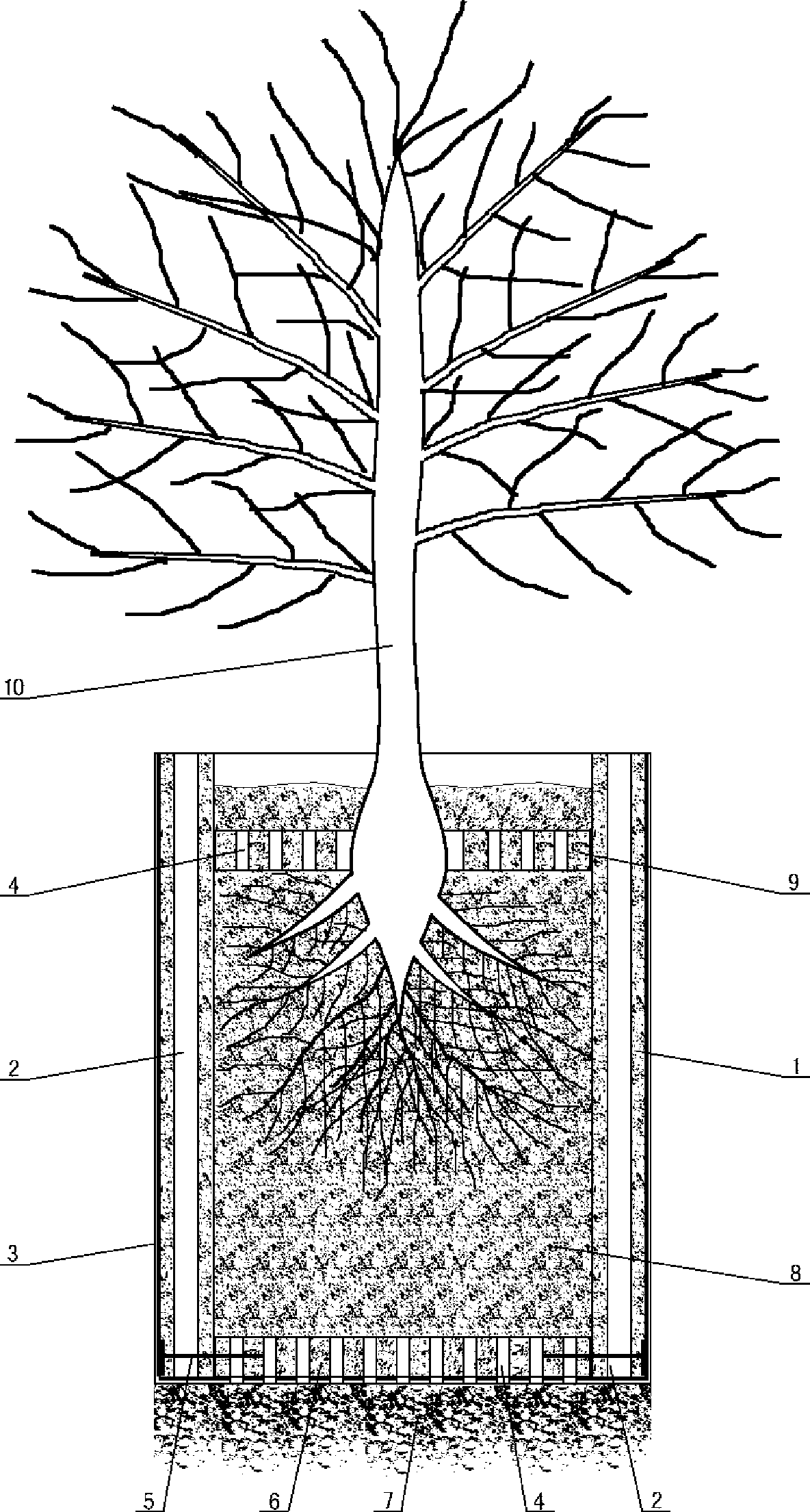

Compressed straw sustained-release fertilizer planting device covered with knitting bag load-bearing container

InactiveCN101480149AGood sustained releaseAchieve sustained releaseCultivating equipmentsForestryAgricultural engineeringPlastic film

The invention relates to a compacted straw slow-release fertilizer planter sleeved with braided bag bearing container. Straw is compacted into an integrated straw cylinder by an extrusion device, or the straw is compacted into straw plates, or straw tubes, or straw rods by the extrusion device; the straw plates, or the straw tubes, or the straw rods are spliced and combined into a straw cylinder by connecting a positioning device, and a straw bottom and a straw cover which are made of compacted straw are arranged in the straw cylinder in a matching way; a planting opening is arranged on the straw cover, and the bottom of the straw cylinder is fixedly connected with the straw bottom through the positioning device to form a container; a braided bag with a bottom, the shape of which is matched with the shape of the container, is sleeved on the container; liftinglugs are arranged at the upper end of the braided bag, and a plastic film without a bottom is compounded between the outer wall of the straw cylinder and the braided bag; and ventholes are uniformly arranged on the straw cylinder, the straw bottom and the straw cover. The device can naturally and slowly release the fertilizer and emit carbon dioxide in the process of decay to facilitate the absorption of leave surfaces of the seedling, meanwhile, the device self becomes less tight and has good air permeability performance to facilitate the growth of the nursery stock root system.

Owner:ZIBO ENVIRONMENTAL PROTECTION TECH CO LTD +1

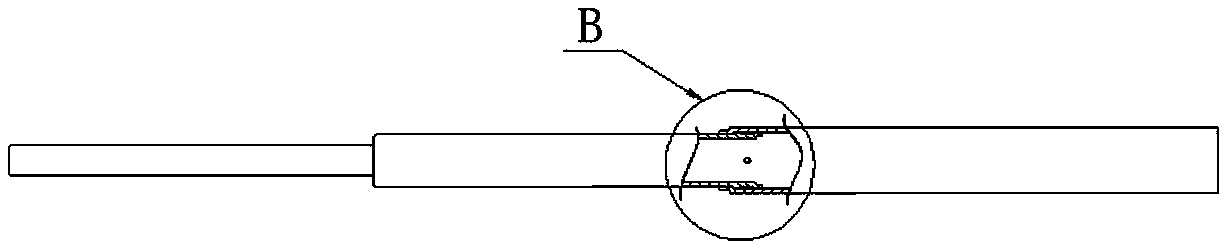

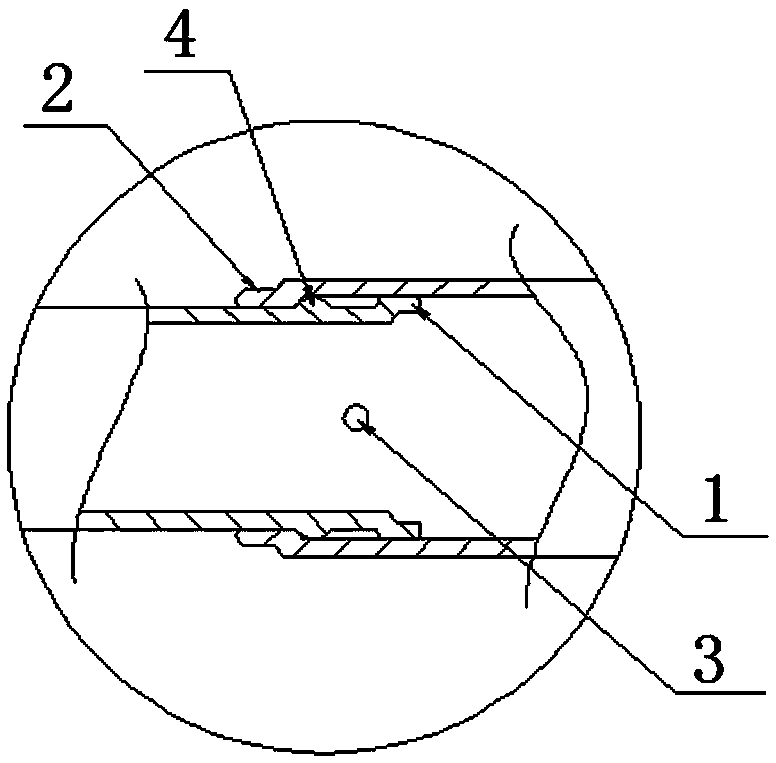

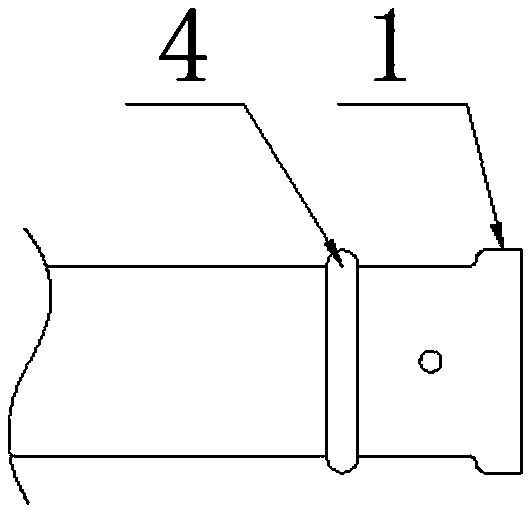

Method of manufacturing boron coated straws for neutron detection through spiral winding and welding

ActiveUS20180021827A1Increasing the thicknessMinimizes operator interventionWelding/soldering/cutting articlesMetal working apparatusEngineeringBoron

A method and apparatus are disclosed with a continuous straw forming process for spiral winding boron-coated foil into a rounded tube or cylinder with an overlap and tight contact between the spiral edges, and a welding process utilizing a high precision fiber laser to weld the spiral seem forming a straw tube.

Owner:PROPORTIONAL TECH

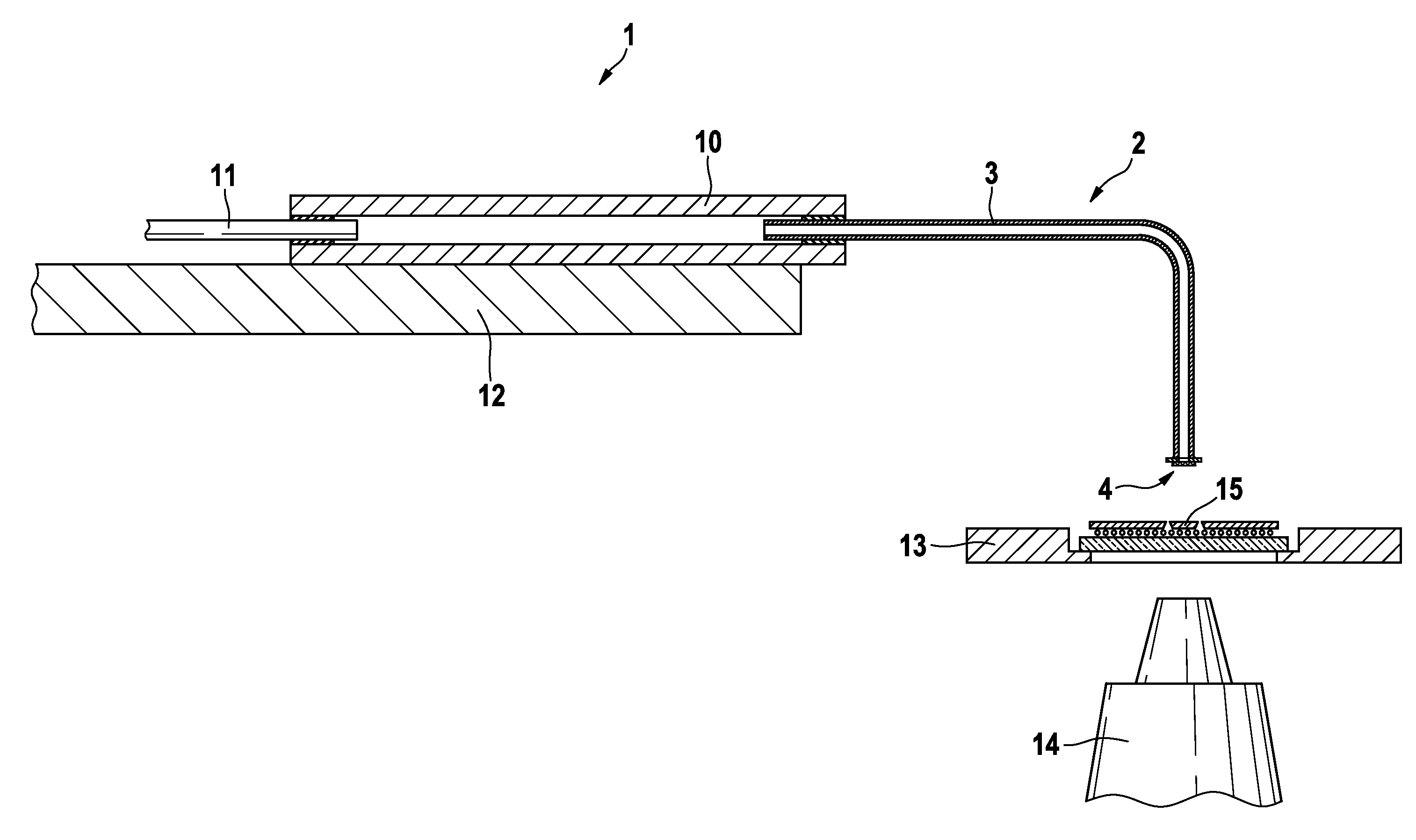

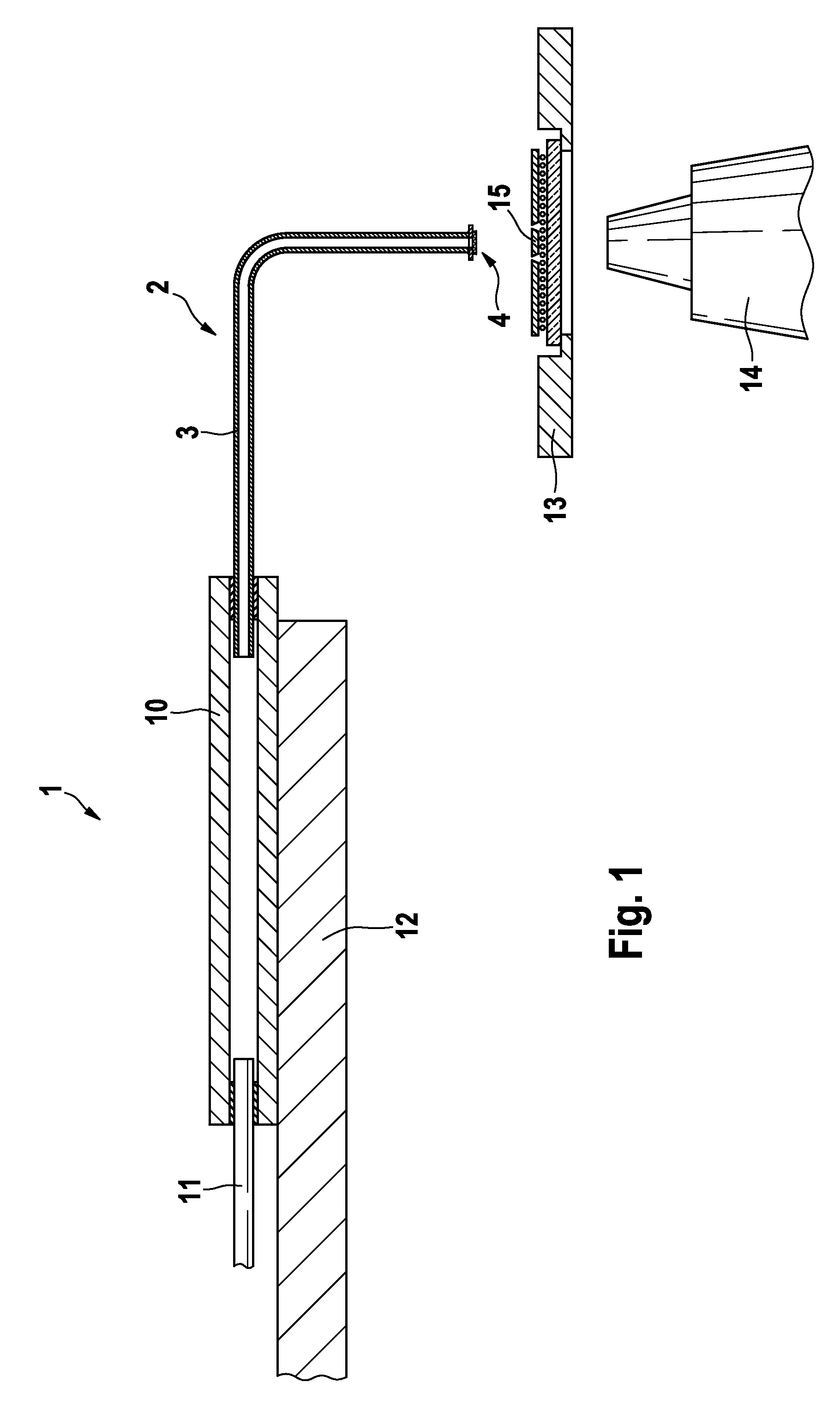

Method and device for transferring a microscopic, isolated sample, micro-dissection system comprising such a device and method for producing a nano-suction means

ActiveUS20110061476A1Eliminate disadvantagesAvoid damageLamination ancillary operationsWithdrawing sample devicesBiomedical engineeringStraw tube

A method and a device for transferring a microscopic, insulated sample, particularly a membrane-supported micro-dissected specimen, from an object table to an analysis arrangement, with a suction apparatus comprising a nano-suction means with a suction tube and a terminal membrane and a vacuum / overpressure unit which can be coupled to the nano-suction means for sucking or blowing the sample onto or from the terminal membrane; and a carrier apparatus for carrying the nano-suction means, which can be moved by means of an associated positioning unit for positioning the nano-suction means exactly in a sample removal position for sucking the sample onto the terminal membrane and in a sample release position for blowing the sample from the terminal membrane. A micro-dissection system, comprising such a device and a method for the production of a nano-suction means that is used in such a device.

Owner:THALHAMMER STEFAN DR

Method for cultivating seedling using compressed straw seedling cultivation cartridge packed with isolation bag

A seedling culture method using a compacted straw seedling culture cylinder with a sleeved isolation pocket is characterized in that straw is compacted into a straw cylinder by an extrusion device, or a straw cylinder which is spliced and combined by straw tubes or straw rods by connecting a positioning device; or a straw bottom and a straw cover which are made of compacted straw are arranged in the straw cylinder in a matching way; the bottom of the straw cylinder is fixedly connected with the straw bottom through the positioning device to form a container, and the isolation pocket with ventilation function at the bottom is sleeved on the container; ventholes are uniformly arranged on the straw cylinder, the straw bottom and the straw cover; the container is filled with planting soil, the compacted straw cover is arranged on the surface layer of the planting soil after putting a plant to be planted, and the straw cover is covered with soil again and is watered; the compacted straw cylinders sleeved with isolation pockets are tightly arranged into a honeycomb shape, and the peripheries of the compacted straw cylinders are covered with soil or bricks. The device is easy to manufacture and install, can naturally and slowly release the fertilizer and emit carbon dioxide in the process of decay to facilitate the absorption of the leave surfaces of seedlings, meanwhile, the device self becomes less tight and has good air permeability performance to facilitate the growth of the root systems of the seedlings.

Owner:徐宝安 +1

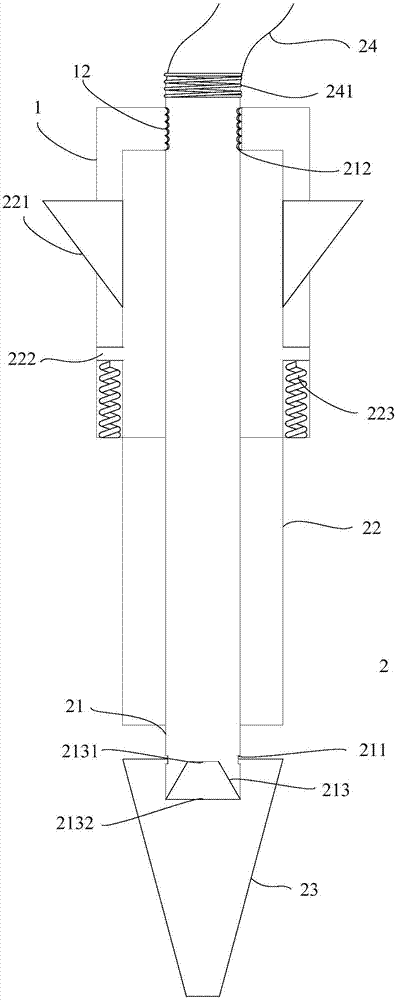

Retractable straw

The invention discloses a retractable straw. The retractable straw is composed of a plurality of tubes, which are arrayed in a manner of gradually increased or decreased diameters, in a sleeve joint manner; the inner and outer tubes can be pulled out or retracted back; a connection structure is arranged at a connection part of each two adjacent tubes; each connection structure is formed by arranging one section of convex tube at an end part of the tube with a small diameter at a connection end of the adjacent tubes, arranging one circle of convex ring at a part which is 6 to 8mm from the convex tube, and one section of necking-down section at an end part of the tube with a large diameter at the connection end of the adjacent tubes; the convex tubes, the outer diameter of the convex rings and the inner diameter of the necking-down sections are matched and in sleeve joint; the convex tubes, the convex rings and the necking-down sections, and the tubes from an integrated structure; at least two fixing buckles are arranged at the connection ends of the tubes provided with the convex tubes, except a first tube and a final tube; the outer surfaces of the fixing buckles on the tubes are grooves; the inner surfaces of the tubes are bulges; the fixing buckles and the tubes form an integrated structure. The retractable straw has the advantages of simple structure, good sealing performance, convenience for utilization and storage and capability of being repeatedly utilized, effectively reduces the environment pollution and is more environmentally friendly.

Owner:HAINING FENGDA ELECTRONICS CO LTD

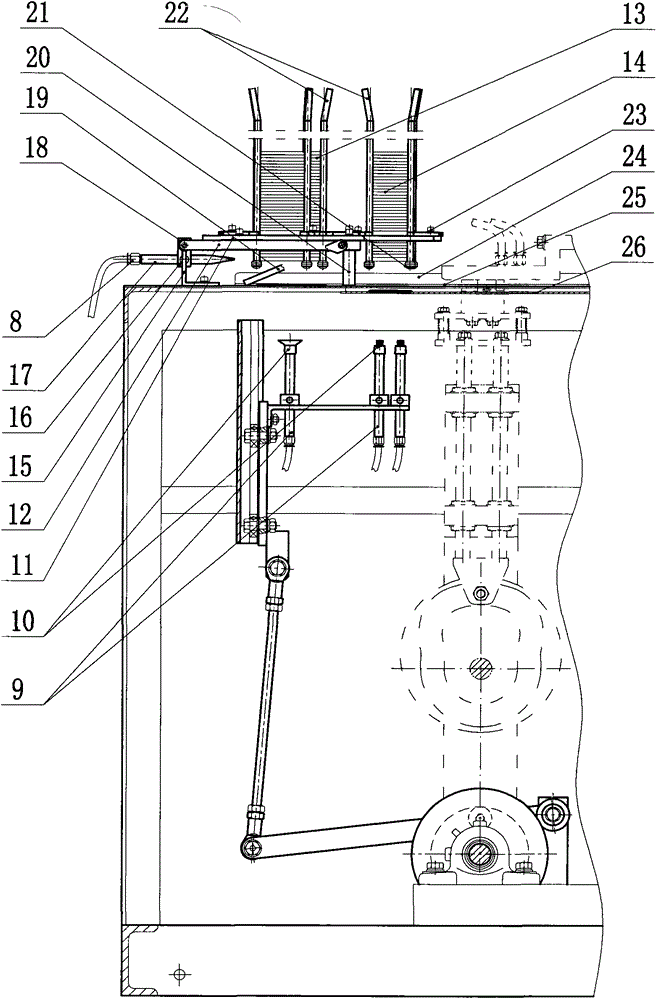

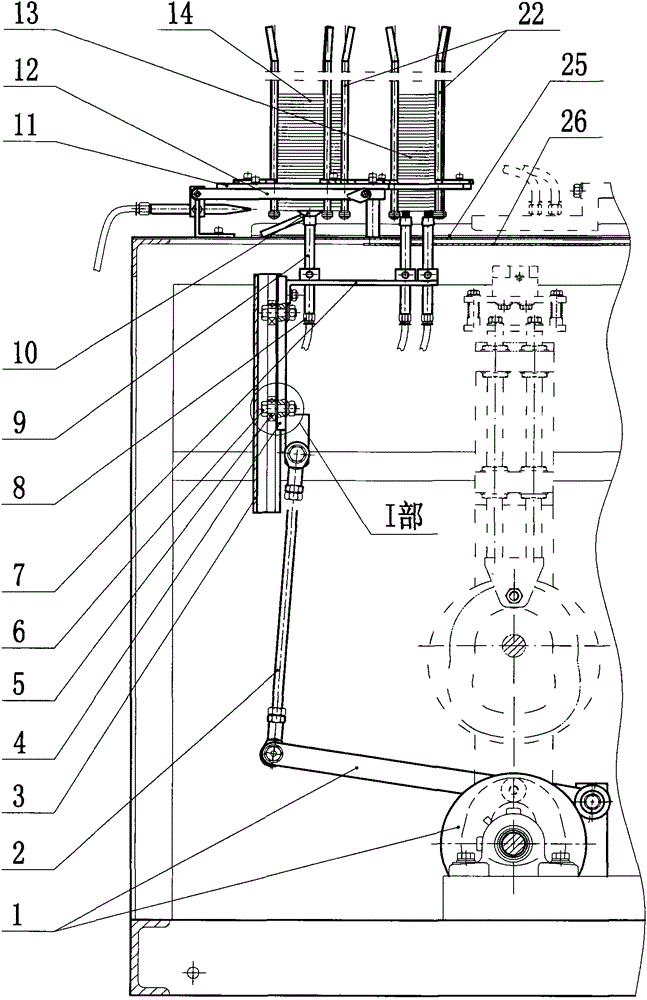

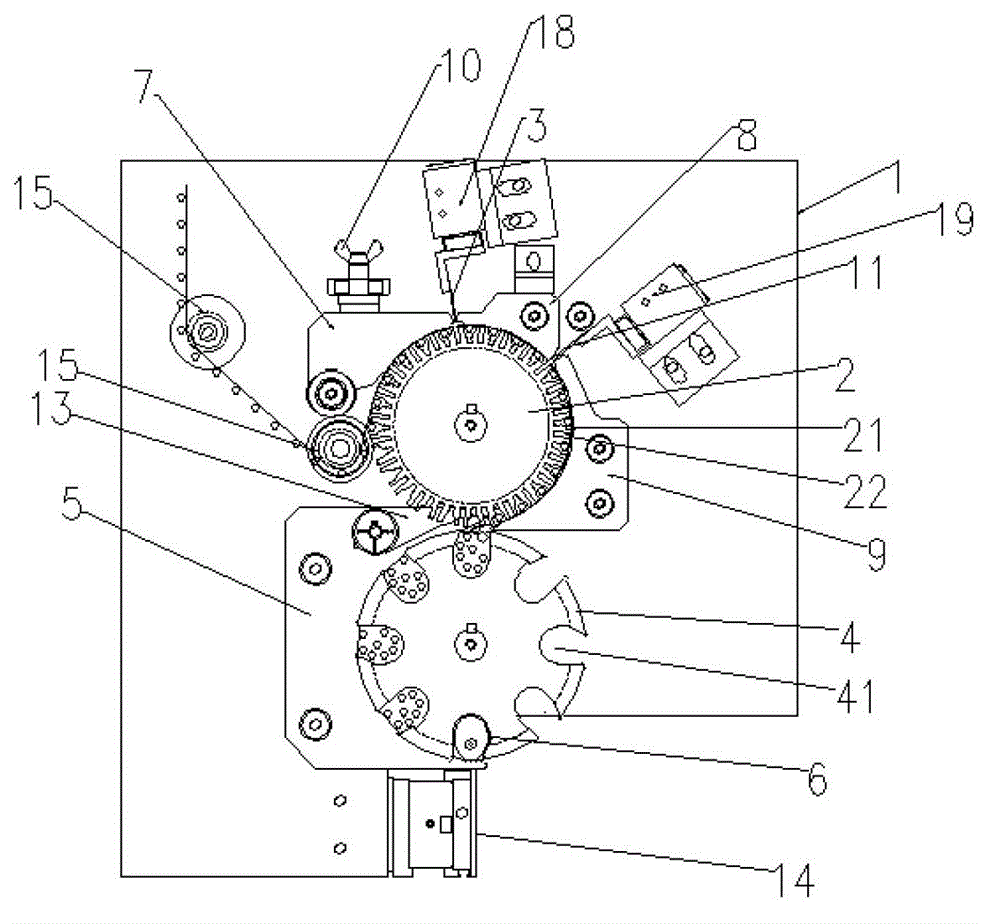

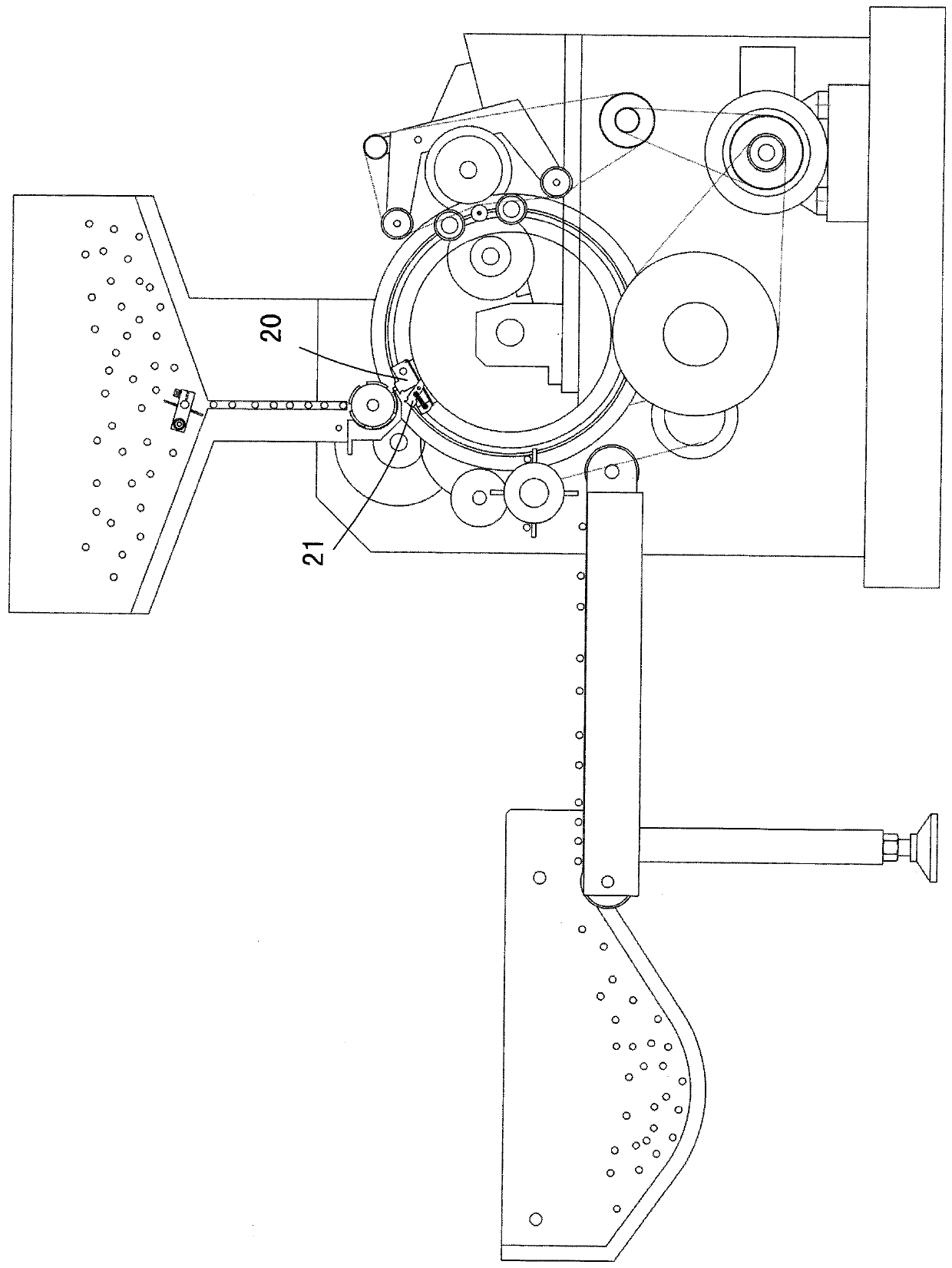

Single suction tube throwing device

InactiveCN103144804AImprove work efficiencySimple structurePackagingMechanical engineeringEnergy consumption

The invention discloses a single suction tube throwing device. The device comprises a material chamber, wherein the bottom of the material chamber is connected with a revolving drum; a plurality of first grooves matched with suction tubes are formed in the outer surface of the revolving drum; the revolving drum is connected with one end of a conveying belt through a slide way; the other end of the conveying belt is connected with a throwing wheel; a plurality of second grooves matched with the suction tubes are formed in the throwing wheel; a slide groove connected with the throwing wheel is arranged below the throwing wheel; and a plurality of bumps are arranged on one side of the upper end of the slide groove. Through the matching among the revolving drum, the slide way, the throwing wheel and the slide groove, the suction tubes which are not arranged in order can be separated from one to one, arranged in rows and thrown singly. The device is simple in structure, low in energy consumption and high in working efficiency.

Owner:GUANGDONG STRONG GROUP

Manufacture method for manufacturing straws through natural material

InactiveCN110480776AGood flexibilitySave resourcesRevolution surface grinding machinesWood treatment detailsSaline waterEngineering

The invention provides a manufacture method for manufacturing straws through a natural material. The manufacture method includes the following steps that firstly, annual reed is selected and used, reed leaves on a reed rod are removed, and the root, with the diameter exceeding 15 mm, and the upper end, with the diameter smaller than 6 mm, of the reed rod are sheared off and removed; secondly, thesheared reed rod is cut off into sections of 5-25 cm; thirdly, one end of each reed rod manufactured in the second step is cut to form an oblique angle of 10-89 degrees through a membrane blade; fourthly, the outer walls are polished through abrasive paper so that the outer walls can be polished smooth; fifthly, abrasive paper of 360 mesh to 600 mesh is used for the outer walls and drills and stretches into the through reed rods to conduct polishing; and sixthly, high-temperature saline water disinfection or high-temperature blow-in disinfection is conducted for 5 minutes, and drying in the sun is conducted. The raw material yield of the straws manufactured through the natural material is large, the manufacture method is easy in manufacture and safe and reliable in usability, the straws can be used in cooperation with stainless steel straws, the reed straws which are abandoned after being used up can be recycled and used for making paper, resources can be saved, and environment protection can be achieved.

Owner:张其浩

Backflow-preventing detachable sucker type liquid sucking device

The invention relates to a backflow-preventing detachable sucker type liquid sucking device which comprises an outer shell and a liquid sucking gun arranged on the outer shell in a penetrating way. The liquid sucking gun comprises a sucking pipe, a gun head boosting device, a sucker and a rubber pipe, wherein the sucking pipe is sleeved by the gun head boosting device, the sucker is connected with one end of the sucking pipe, and the rubber pipe is connected with the other end of the sucking pipe; a backflow preventing device is arranged on a port of one end connected with the sucker of the sucking pipe, the backflow preventing device is in a circular truncated cone shape, an upper opening and a lower opening are formed in the two ends of the backflow preventing device, the upper opening and the lower opening are in cut-through, and the diameter of the upper opening is larger than that of the lower opening; two cut-through grooves are formed in a lateral wall of the outer shell, the sucking pipe is connected with the outer shell, a pair of push blocks and a pair of abutting blocks are arranged on the outer surface of a sucker booster, and the push blocks are arranged on the cut-through grooves in a penetrating mode and can slide in the cut-through grooves; springs are arranged between the abutting blocks and the outer shell, one end of each spring abuts against the corresponding abutting block, and the other end of each spring abuts against the outer shell. The backflow-preventing detachable sucker type liquid sucking device disclosed by the invention has simple structure and convenience in operation, can effectively prevent residual liquid from flowing back, improves operation efficiency and further reduces experimental pollution.

Owner:YANGTZE UNIVERSITY

Convenient purifying mechanism with adjustable dust suction head

The invention discloses a convenient purifying mechanism with an adjustable dust suction head, which comprises a dust collecting pipe, a first connecting pipe, an exhaust fan, a first diverting pipe and a purifying box which communicate in sequence. The upper surface of the purifying box is provided with a water tank, the water tank communicates with a second diverting pipe arranged on the inner top surface of the purifying box through a guide pipe, a plurality of spray heads are arranged on the second diverting pipe at intervals, a filter plate is also arranged inside the purifying box, the filter plate forms a sewage collection cavity with the lower part of the purifying box, and a drain pipe communicating with the sewage collection cavity is arranged on the side surface of the purifyingbox. The convenient dust purifying mechanism overcomes the problems that a plurality of suction pipes are commonly used in the dust treatment device in the prior art to absorb dust, the absorption amount is very limited, the absorption speed is slowed down, the working efficiency is low, the position of the dust suction head is fixed, and the convenience of use is poor.

Owner:江西众安职业卫生技术服务有限公司

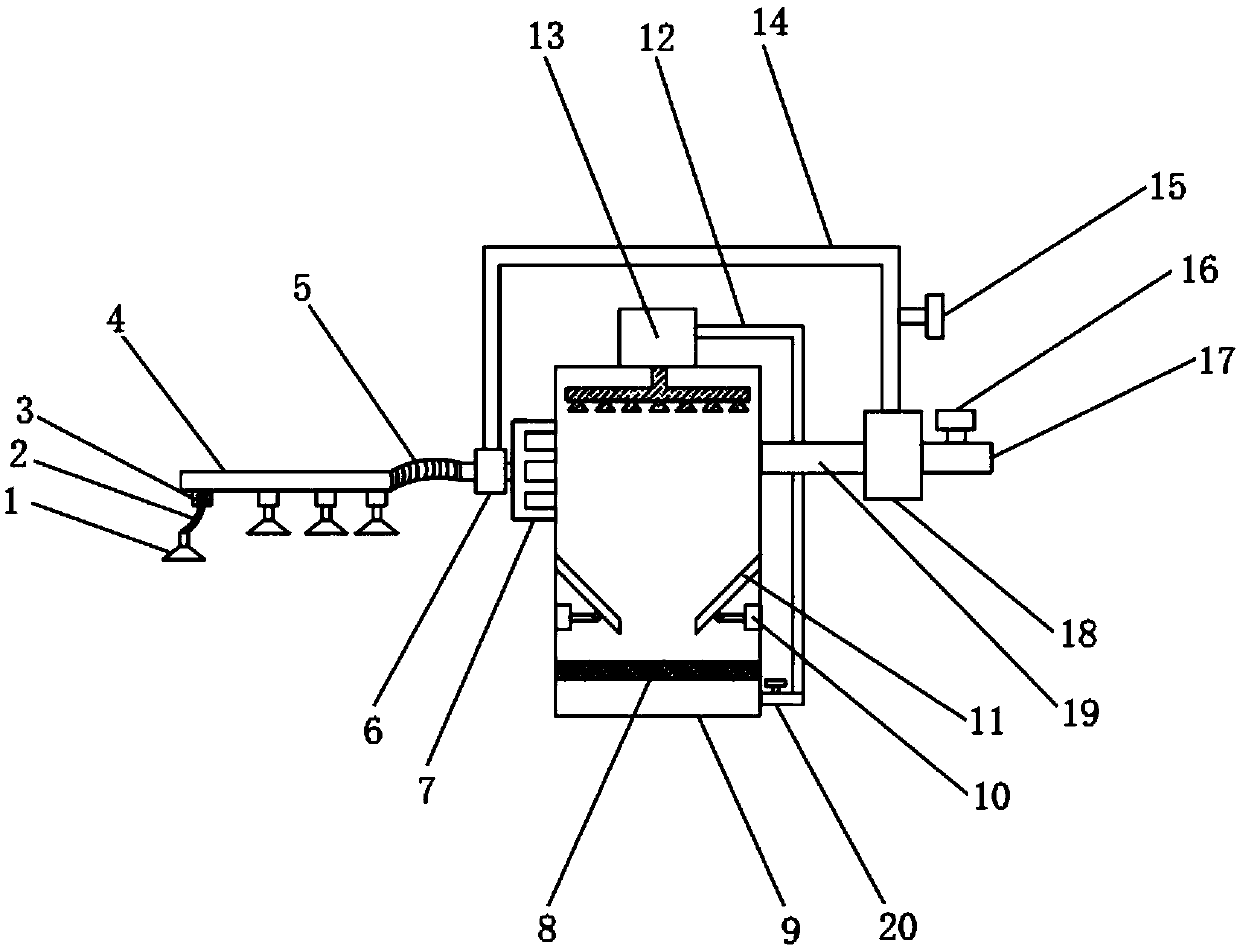

Straw straw cutting and feeding device

The invention discloses a slitting and feeding device for a row straw. A pineapple head and a collector are rotatably positioned on a rack; the outer side of the circumference of the pineapple head is provided with a plurality of straw containing slots and cutter slots at an interval; the outer side of the circumference of the collector is provided with a plurality of straw collection slots; the opening of the straw containing slot between the feeding end and the discharging end of the pineapple head can be covered by a material blocking device; a first cutter can extend into the cutter slot of the pineapple head to cut off the row straw; the cut-off row straws on the discharging side of the pineapple head can be sent into the straw collection slots of the collector by a material guide device; a push rod is positioned on the rack; the straws in the straw collection slots of the collector can be pushed out of the straw collection slots by the push rod; the pineapple head, the collector, the first cutter and the push rod are respectively driven by a first driving device, a second driving device, a third driving device and a fourth driving device to move; the first driving device, the second driving device, the third driving device and the fourth driving device are controlled by a controller to act. According to the slitting and feeding device for the row straw, which is disclosed by the invention, the straw can be fully-automatically slit and conveyed, manpower is saved, slitting can be accurately carried out, and the packaging quality is guaranteed.

Owner:KUSN FASTEC MACHINERY

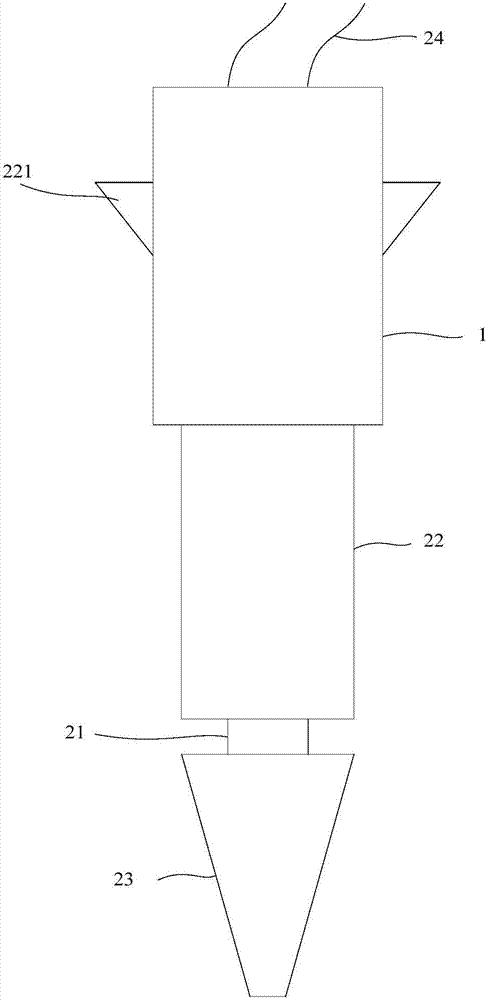

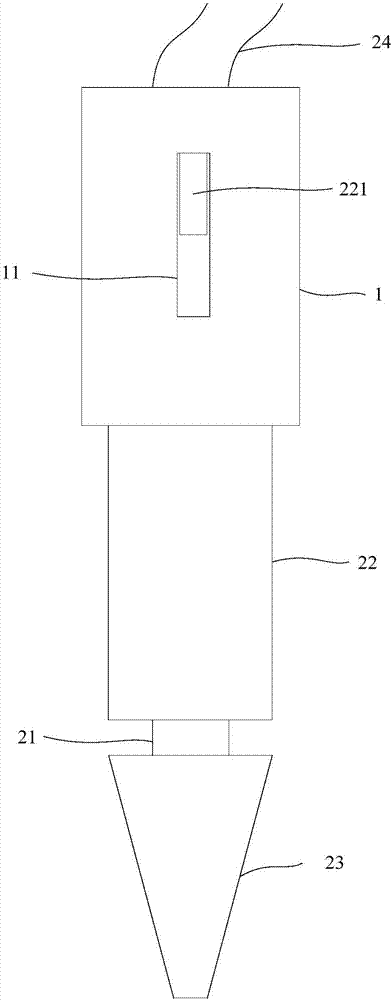

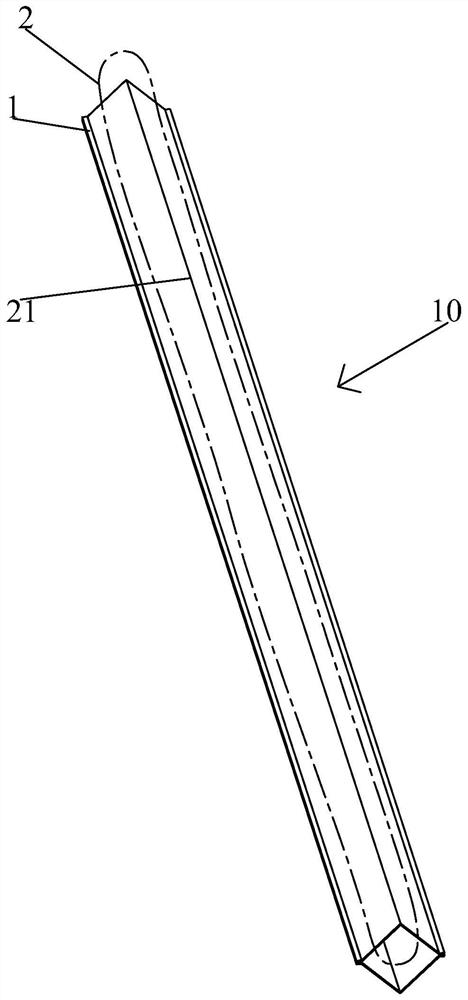

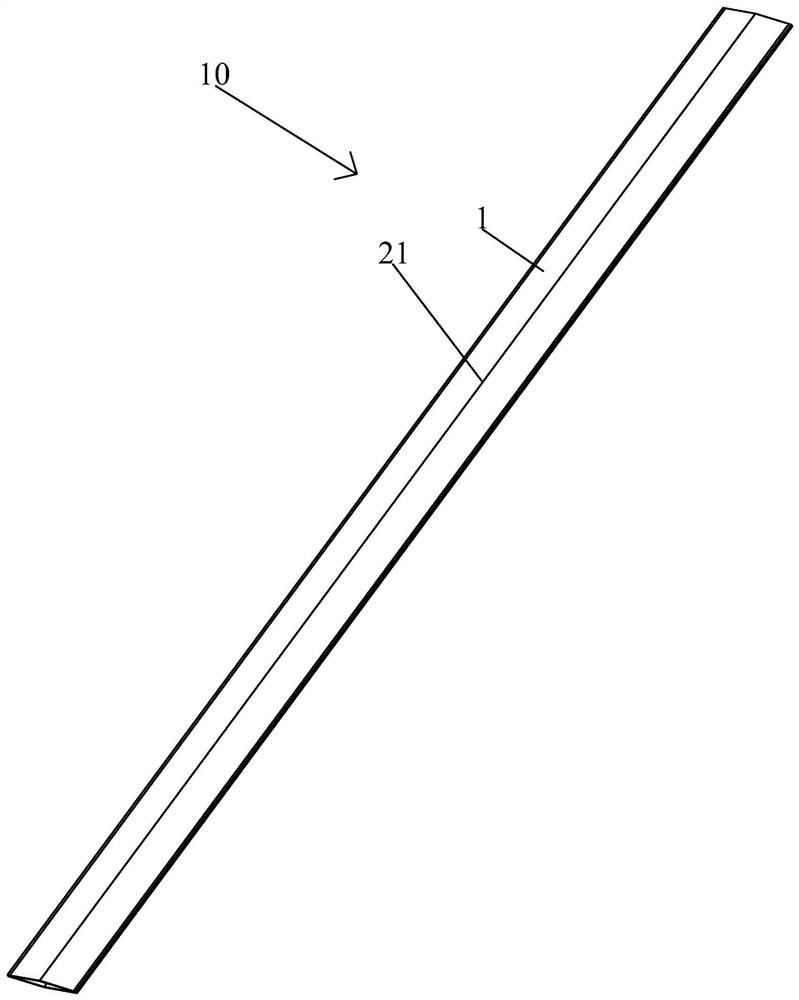

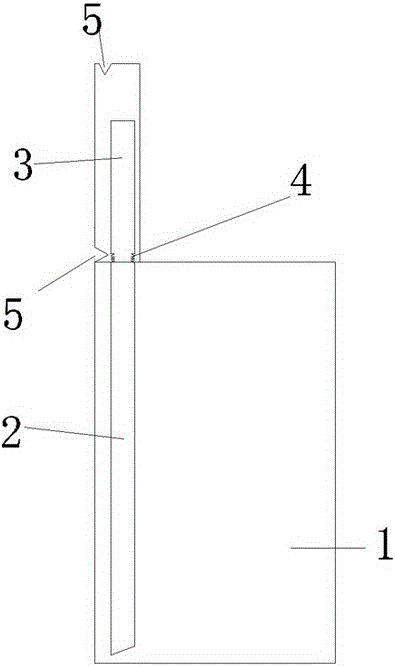

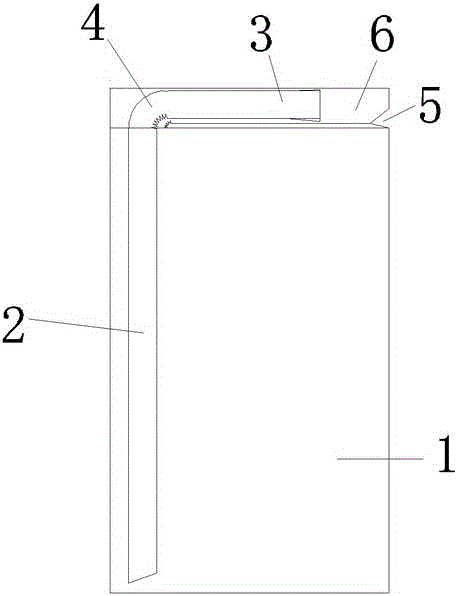

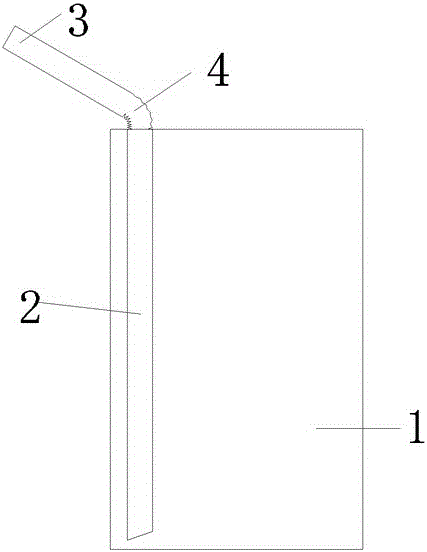

Straw tube with variable tube diameter

InactiveCN113455875AReduce volumeNot easy to retract and deformDwelling equipmentTablewaresSoft materialsMechanical engineering

The invention discloses a straw tube with variable tube diameters. Two sides of two deformation sheets are mutually jointed to form a tube body, and the middle part of each deformation sheet is an easy-to-deform area for controlling the size of the tube diameter by extrusion. The deformation sheets are made of a plurality of hard materials, and the adjacent hard materials are connected through soft materials. The deformation sheets are made of an elastic material. The deformation sheets are made of a paper material, each deformation sheet is provided with at least one pre-pressing line, and the pre-pressing line is located in the easy-to-deform area. According to the straw capable of being transformed into a tubular shape from a straight sheet shape, the size of the straw during transportation at ordinary times can be greatly reduced, the space utilization rate of transportation, storage and the like is increased, and the straw is high in structural strength and convenient to machine.

Owner:厦门鑫一带风帆机电有限公司

A kind of compact straw slow-release fertilizer planter with woven bag load-bearing container

InactiveCN101480149BGood sustained releaseAchieve sustained releaseCultivating equipmentsOrganic fertilisersAgricultural engineeringPlastic film

The invention relates to a compacted straw slow-release fertilizer planter sleeved with braided bag bearing container. Straw is compacted into an integrated straw cylinder by an extrusion device, or the straw is compacted into straw plates, or straw tubes, or straw rods by the extrusion device; the straw plates, or the straw tubes, or the straw rods are spliced and combined into a straw cylinder by connecting a positioning device, and a straw bottom and a straw cover which are made of compacted straw are arranged in the straw cylinder in a matching way; a planting opening is arranged on the straw cover, and the bottom of the straw cylinder is fixedly connected with the straw bottom through the positioning device to form a container; a braided bag with a bottom, the shape of which is matched with the shape of the container, is sleeved on the container; liftinglugs are arranged at the upper end of the braided bag, and a plastic film without a bottom is compounded between the outer wall of the straw cylinder and the braided bag; and ventholes are uniformly arranged on the straw cylinder, the straw bottom and the straw cover. The device can naturally and slowly release the fertilizer and emit carbon dioxide in the process of decay to facilitate the absorption of leave surfaces of the seedling, meanwhile, the device self becomes less tight and has good air permeability performance to facilitate the growth of the nursery stock root system.

Owner:ZIBO ENVIRONMENTAL PROTECTION TECH CO LTD +1

Novel straw

The invention discloses a novel straw. The novel straw comprises a box body, wherein the box body is internally provided with object fetching cavities in a bilaterally symmetric manner; each object fetching cavity is provided with a forward opening; the upper end wall of each object fetching cavity is fixedly provided with an upwardly extending first fixing block; each first fixing block is internally provided with a first through cavity penetrating up and down; the top of each first through cavity is communicated with a transfer chamber; the front end wall of eachtransfer chamber is in running fit connection with a first rotating rod; the outer surface of each first rotating rod is fixedly provided with a rotating wheel located in the transfer cavity; the outer surface of each rotating wheel is circumferentially provided with a plurality of evenly distributed partitions; the upper end wall of each transfer cavity is fixedly provided with a second fixing block. The straw disclosed by the invention is simple in structure and convenient to use, and the straw on a vending machine is convenient to manage.

Owner:QUZHOU SHUNAN ELECTRONICS COMMERCE CO LTD

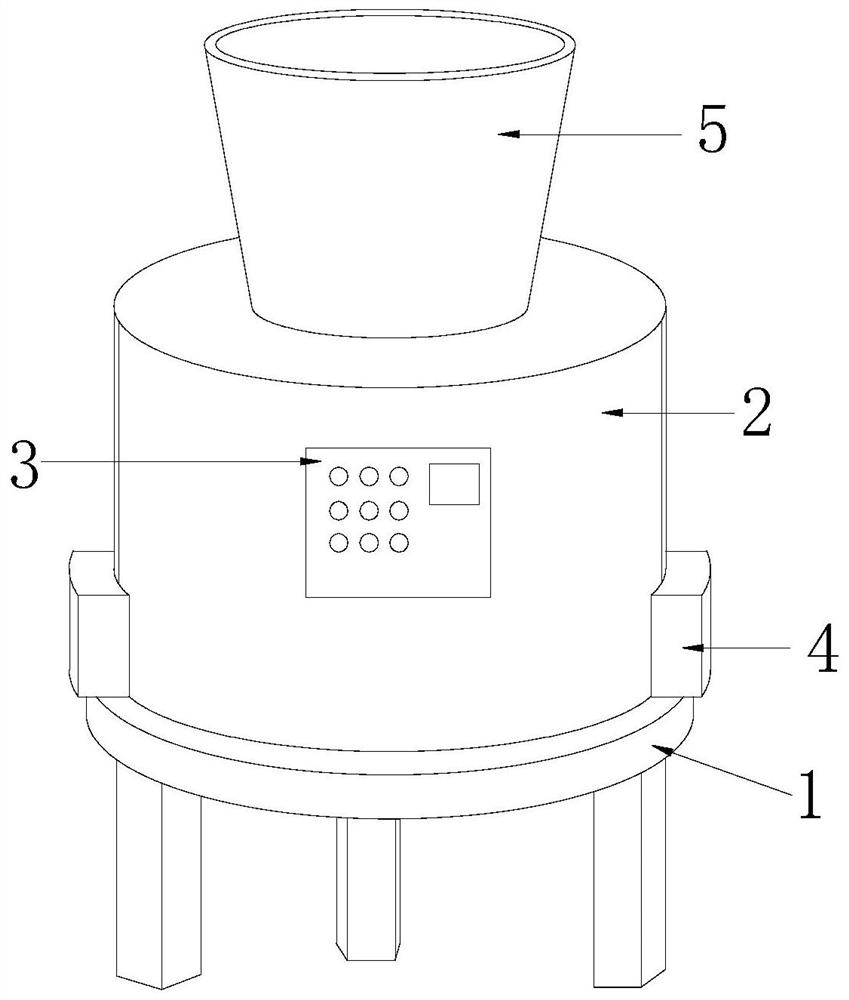

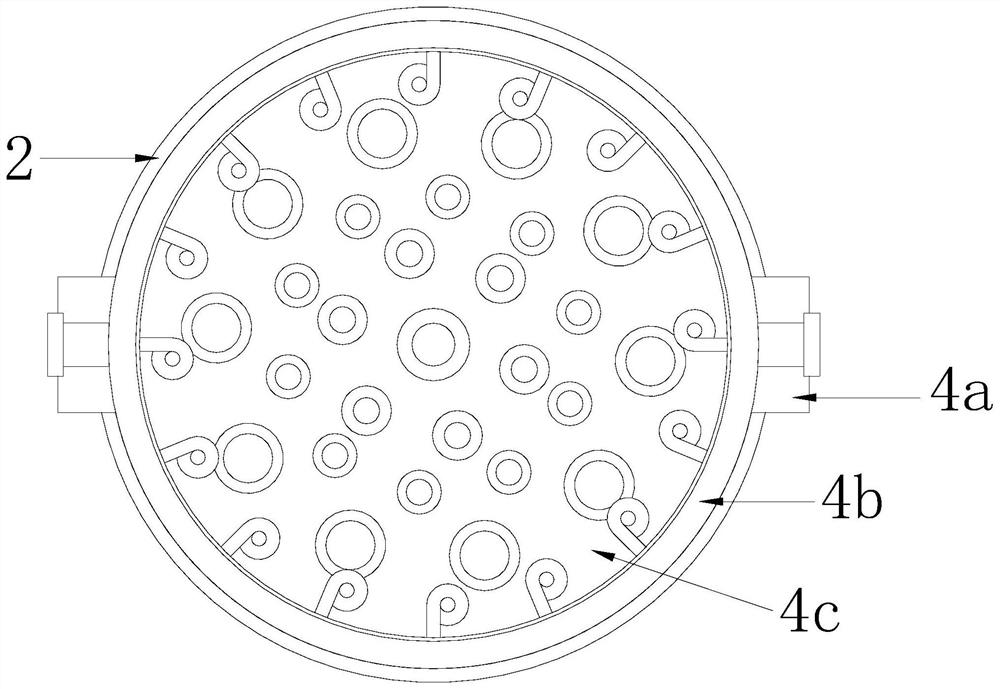

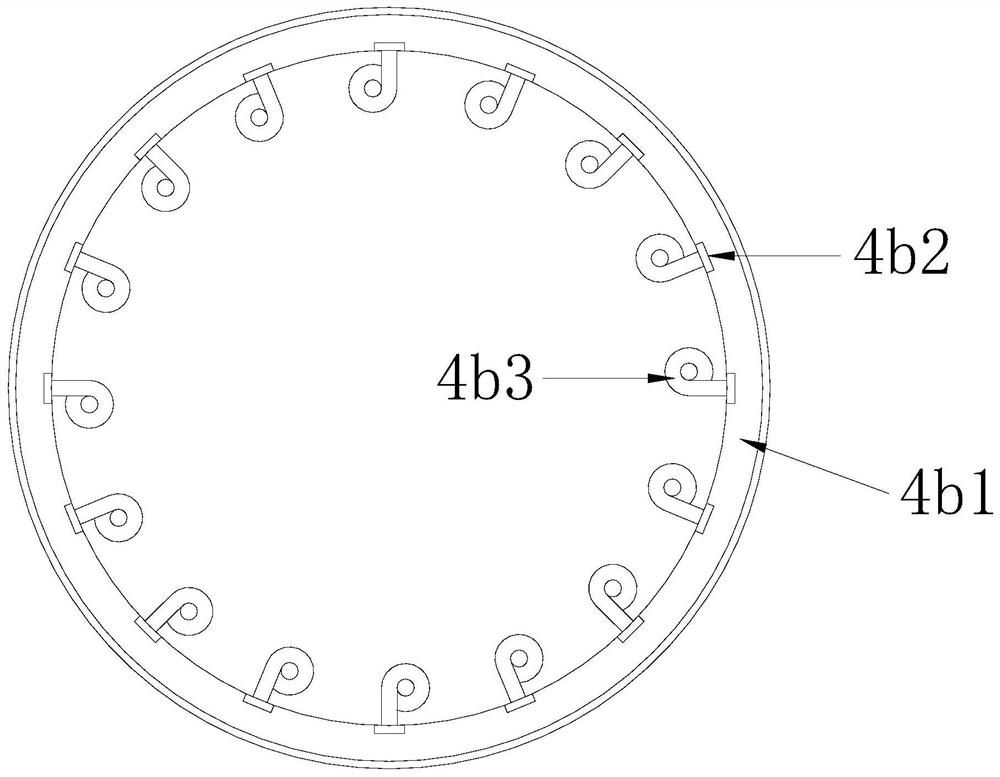

A cellulose raw material preservative device that can save preservative liquid

ActiveCN113134883BGuaranteed superiorityNot easy to cleanImpregnation spraying apparatusWood treatment detailsCelluloseProcess engineering

The invention relates to the field of lignocellulose production, in particular to an internal and external antiseptic device for cellulose raw materials that can save antiseptic liquid. The technical problem of the present invention is to provide an internal and external anti-corrosion device for cellulose raw materials that can save anti-corrosion liquid. The technical embodiment of the present invention is: an internal and external anticorrosion device for cellulose raw materials that can save antiseptic liquid, including a support frame, a control panel, a controllable tilt system and a cutting and dislocation system; the controllable tilt system is connected with the support frame; The misalignment system is connected to the support frame. The present invention realizes that by cutting off the middle part of the straw tube, the preservative liquid can not only flow into the inside of the straw tube from both sides of the straw, but also flow into the inside of the straw tube from the middle part of the straw. Self-rotating, so that both the inner and outer surfaces of the straw tube can fully contact with the antiseptic solution, saving a lot of antiseptic solution.

Owner:晋州市谊诚纤维素有限公司

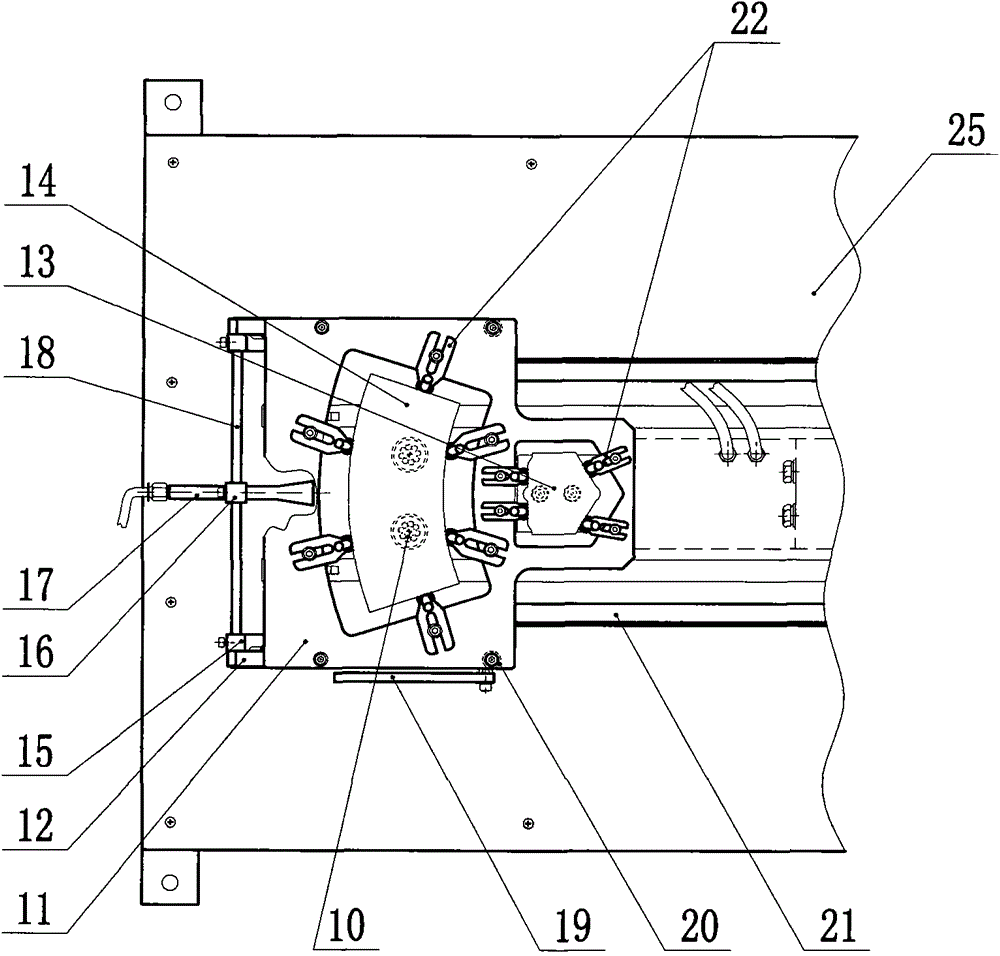

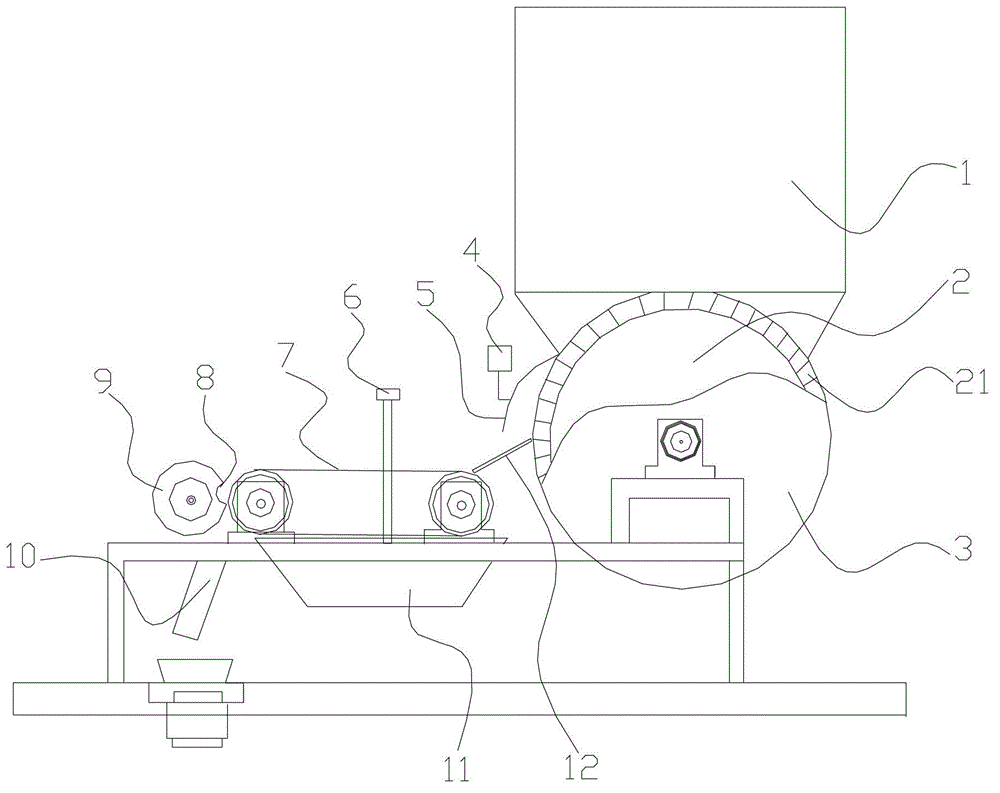

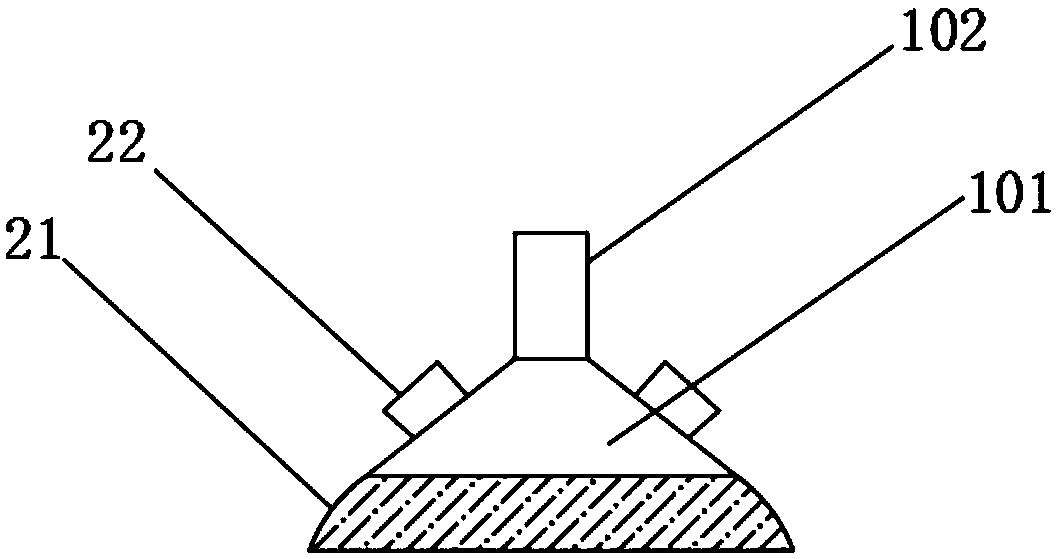

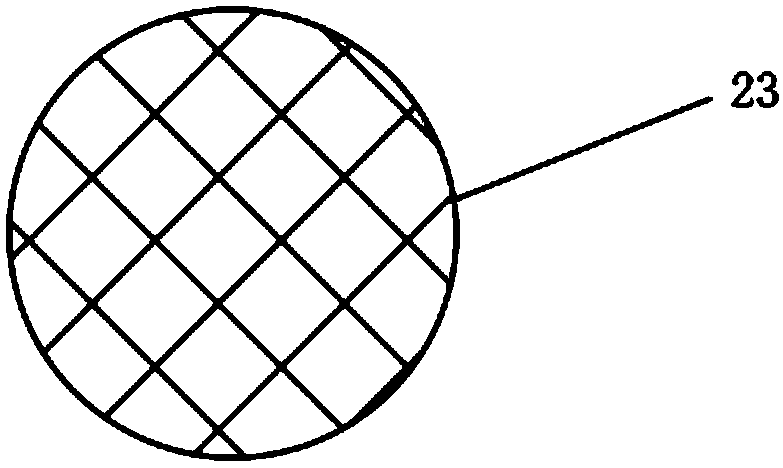

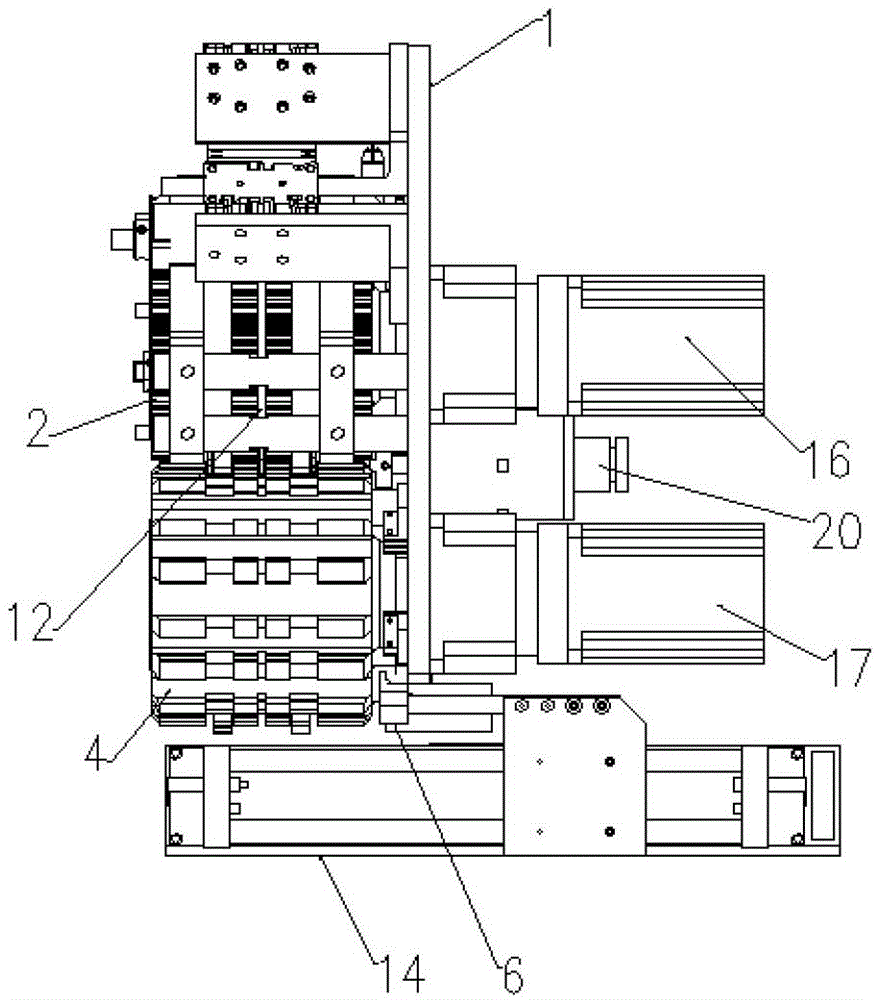

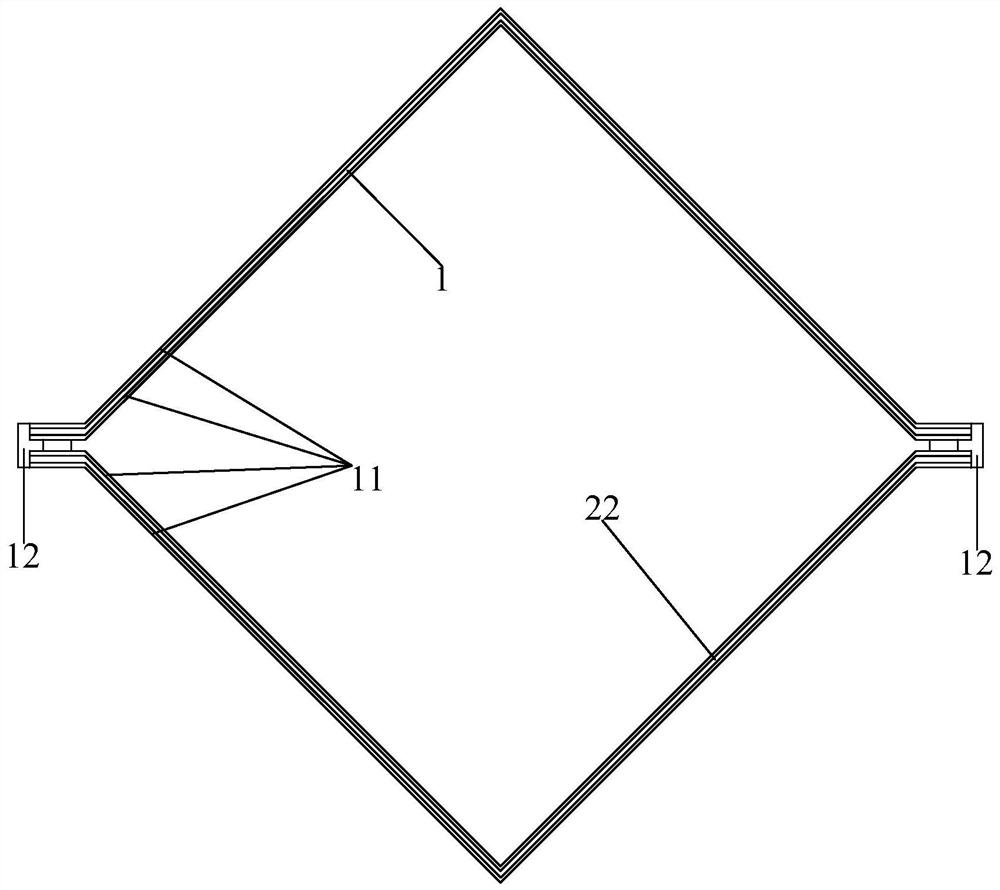

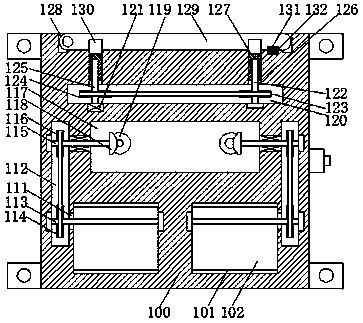

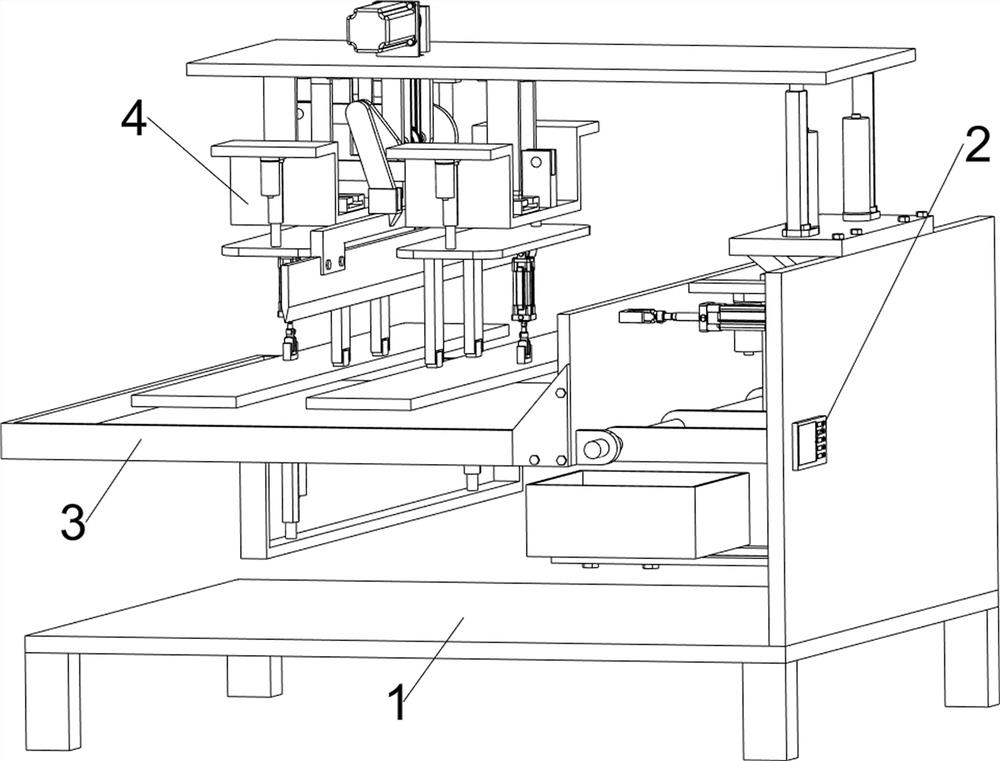

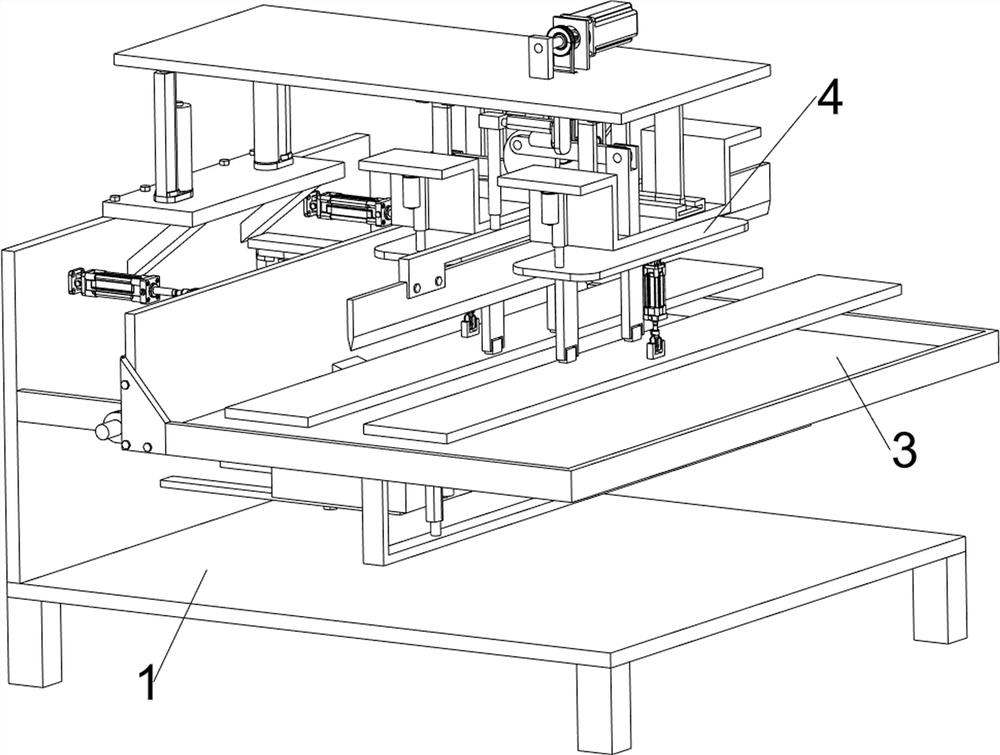

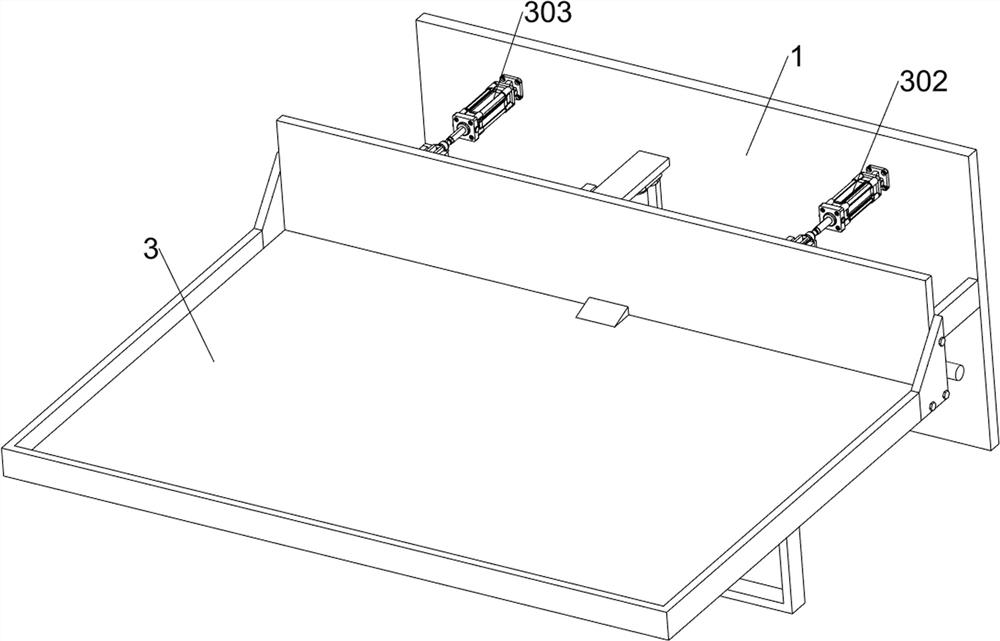

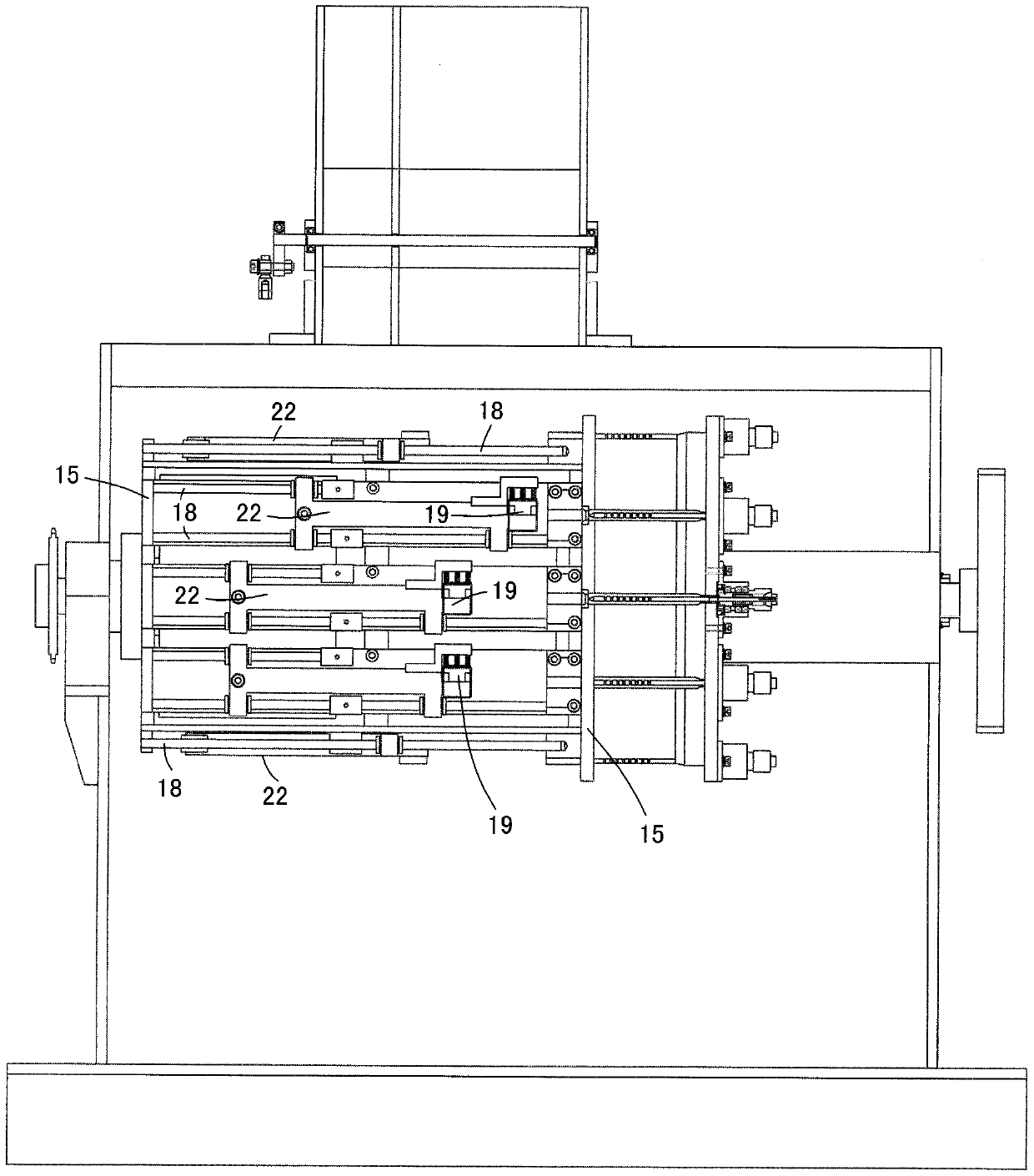

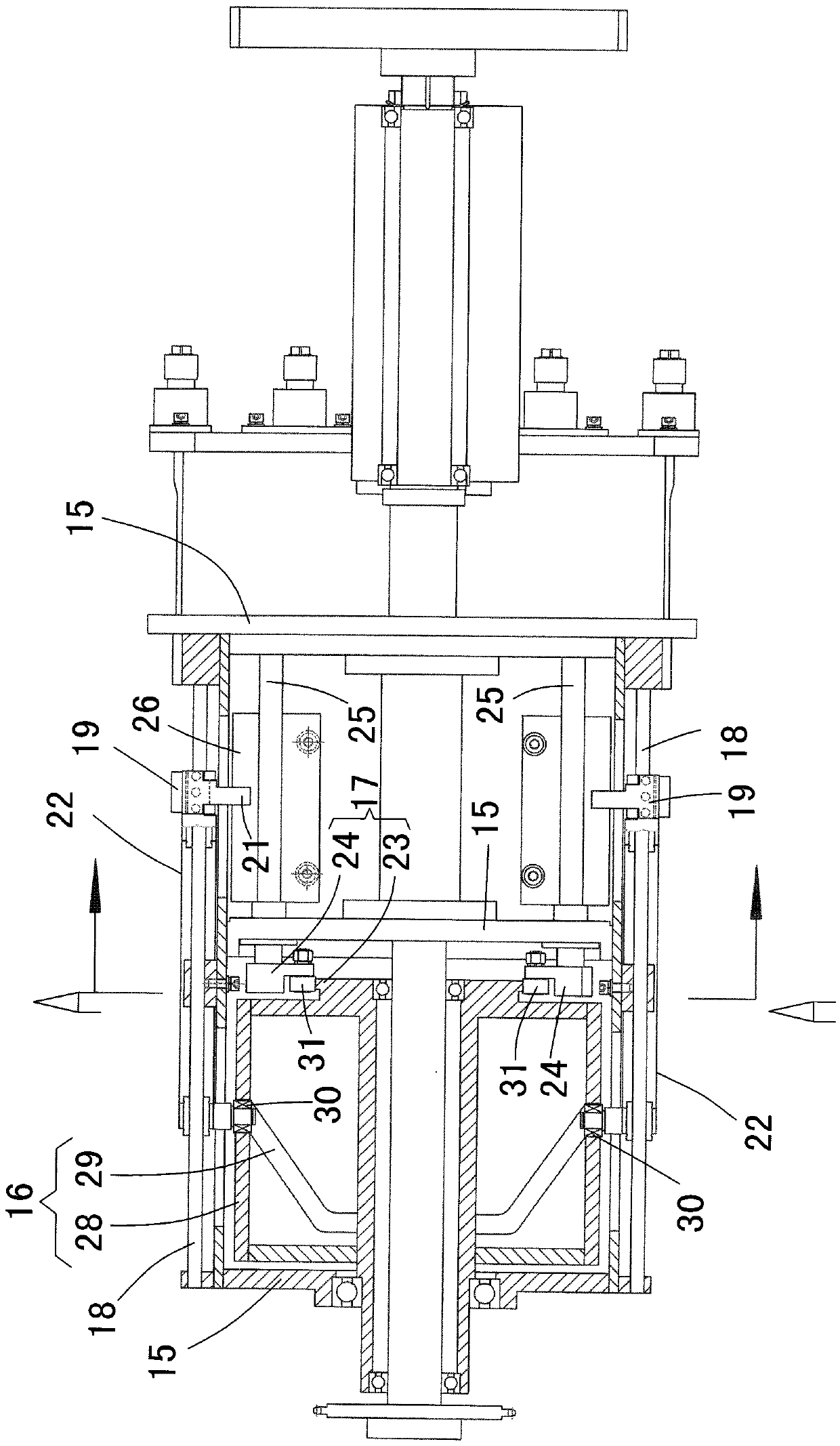

Paper straw bent head forming clamp rotary table mechanism

PendingCN109895458ARealize mechanized workImprove efficiencyPaper/cardboard articlesMechanical engineeringStraw tube

A paper straw bent head forming clamp rotary table mechanism comprises clamp rotary tables, axial movement transmission devices and clamp opening and closing transmission devices. Axial tracks are arranged on the clamp rotary tables and distributed on the clamp rotary tables in the circumferential direction. Clamp devices are arranged on the axial tracks and connected with the axial movement transmission devices and clamp opening and closing transmission devices. The paper straw bent head forming clamp rotary table mechanism can clamp paper straws and then conduct rotating movement, the clamped paper straws can be subjected to axial movement in the rotating movement process, and the axial movement enables the paper straws to sleeve a core rod mold to conduct bent head forming. The paper straws are clamped and moved, and can cooperatively participate in the paper straw bent head forming operation, so that the mechanical operation is achieved, and the efficiency is higher.

Owner:WENZHOU FENGMING MACHINERY CO LTD

Preparation method of high transparent degradable material and suction tube

ActiveCN102070828BEnsure safetyHigh transparencyTablewaresTubular articlesBenzoic acidPolymer science

The invention provides a preparation method of a high transparent degradable material. The preparation method is characterized by comprising the following steps of: 1) preparing raw materials: based on weight percent, weighing the following raw material components: 95-98 of polypropylene resin, 1-5 of polystyrene resin, 0.01-0.05 of food-grade benzoic acid and 0.1-0.5 of modified paraffin; 2) mixing the components to form a modified polypropylene resin mixing material; and 3) carrying out low-temperature standing on the modified mixing material for later use. The invention also discloses a method for preparing a suction tube by using the above materials. The method for preparing the suction tube comprises the following steps of: 4) preparing a suction tube extruding main machine and a round die head matched with the main machine; 5) feeding the modified mixing material in the extruding main machine to obtain a continuous round hollow suction tube; and 6) cutting the prepared continuous linear type suction tube to suction tube sections. The invention further provides the suction tube prepared by the method. The material provided by the invention is highly transparent and degradable, the method is scientific and reasonable, the production efficiency is high, the product property is good, and the cost is low.

Owner:义乌市双童日用品有限公司

A detackification device for a pharmaceutical pulverizer

ActiveCN112657620BMake sure to wipe off the fitEasy to solveGrain treatmentsReciprocating motionEngineering

The invention discloses a debonding device for a pharmaceutical pulverizer, the structure of which comprises a bracket, a pulverizing cylinder, a controller, an adhesion inhibiting device and a feeding hopper. Beneficial effects: the present invention utilizes the cooperation of the provided removing structure and the power device, so that the pushing part is stretched under the action of the airflow in the ring cavity, and when the power device is energized, the pushing and removing structure is driven to synchronize Up and down reciprocating movement, so as to touch and wipe the crushing rod inside the crushing cylinder, so as to avoid remaining powder, and then ensure the wiping and cooperation of the remaining powder inside the crushing cylinder. Under the action of the airflow inside the cavity, the powder scraped off by the scraping structure is sucked in a concentrated manner, and with the cooperation of the sticky strip, the absorbed powder adheres to its surface to avoid powder lifting. At the same time, the sleeve hole is fitted with the crushing rod inside the crushing cylinder, and the attached powder on the surface of the crushing rod is auxiliary removed.

Owner:HUNAN DONGJIAN PHARMA CO LTD

Bag with straw inside

The invention discloses a bag with a straw inside. The bag comprises a bag body, a straw inner section, a straw outer section, a straw folding elastic place, a bag tearing port and a bag tearing head, and is characterized in that the straw inner section is put in the bag body; a concave part of the straw folding elastic place is tightly connected with an opening part of the bag body; the bag sealing head is arranged above a bag body outlet; the bag body is connected with the bag sealing head; the straw outer section is sealed by the bag sealing head; and the bag tearing port is formed in the bag sealing head. The bag is simple in structure, needs no insertion of the straw, saves a straw taking action, is convenient, saves the time, and can suck foods by tearing off a seal.

Owner:WENZHOU GOOD TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com