Single suction tube throwing device

A technology of dispensing device and straw, applied in packaging and other directions, can solve the problems of large power, high energy consumption, low correct dispensing rate, etc., and achieve the effects of simple structure, low energy consumption and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples.

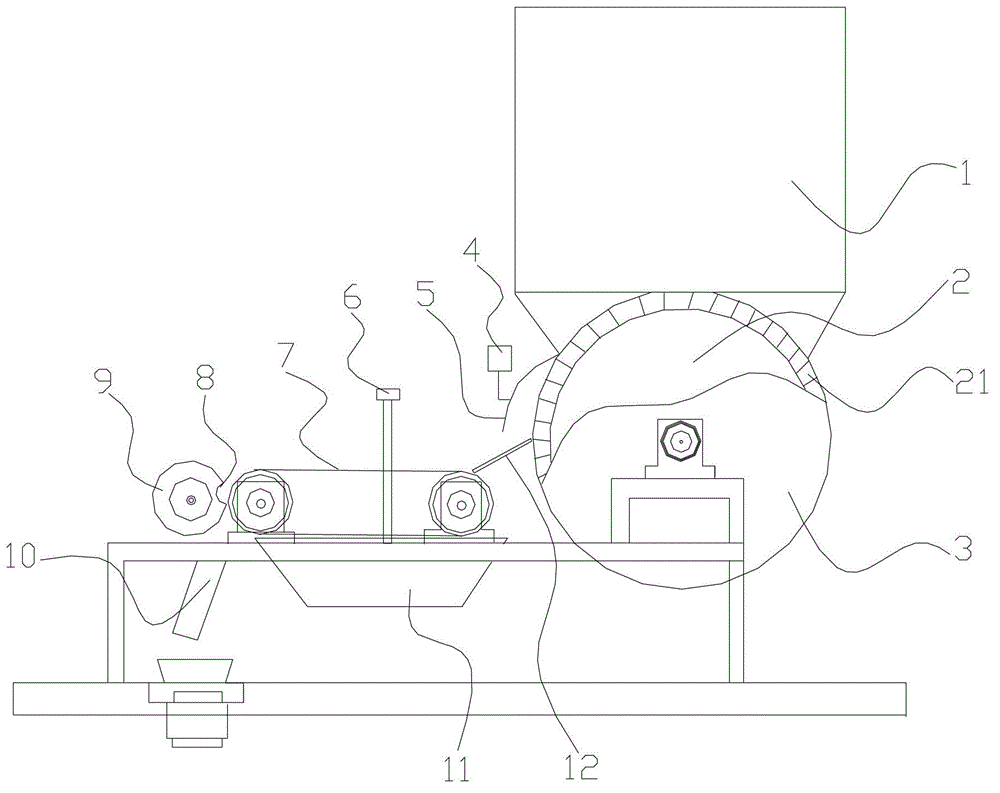

[0016] refer to figure 1 , a single straw delivery device provided by the present invention includes a feed bin 1, a drum 2, a cylindrical shell 3, a conveyor belt 7, a detection mechanism 6, a delivery wheel 9, a chute 10 and a Recycling agencies11. The bottom of the silo 1 is connected with a cylindrical shell 3, and a drum 2 is arranged in the cylindrical shell 3, and the outer surface of the drum 2 is equidistantly provided with a plurality of first grooves 21, the first grooves 21 Size matches the straw. Put the messy straws in the bin 1 , and the straws in the bin 1 enter the first groove 21 on the drum 2 during the continuous rotation of the drum 2 . The cylindrical housing 3 is provided with a drum door 5 matching with the first groove 21 , the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com