Straw tube with variable tube diameter

A pipe diameter and straw technology, which is applied in the field of variable pipe diameter straws, can solve the problems of low straw transportation efficiency, complicated processing process of environmental protection straws, poor structural design strength of environmental protection straws, etc. The effect of small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

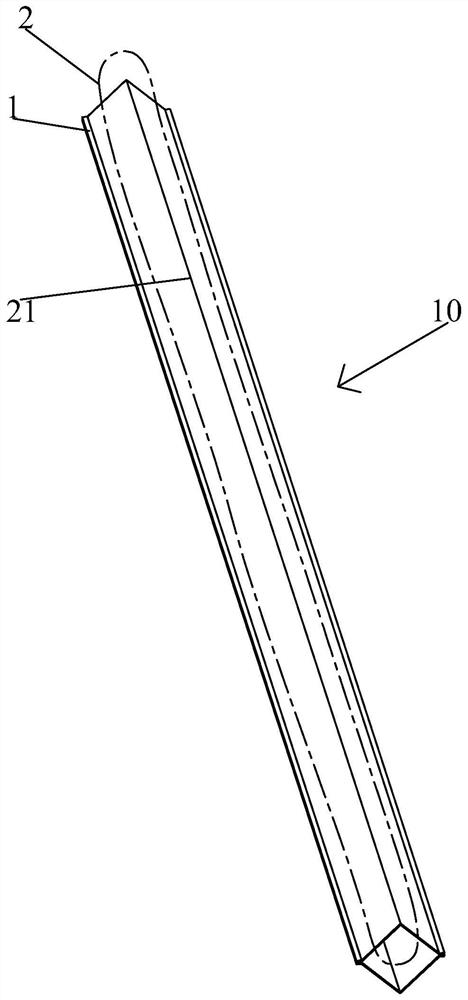

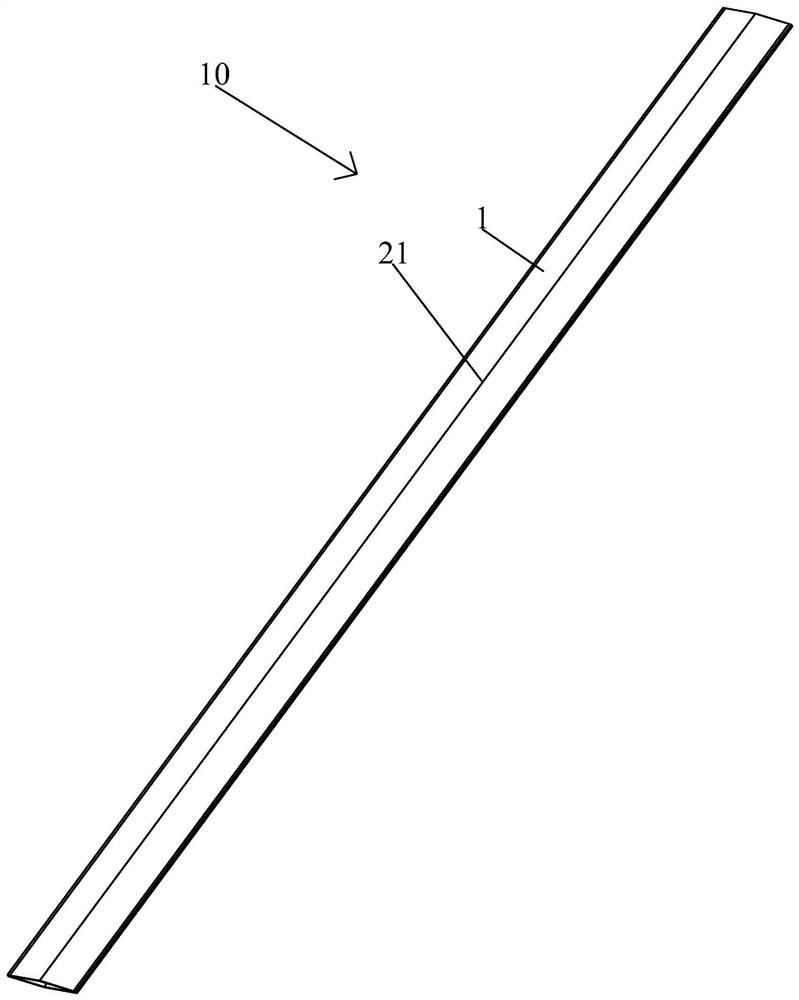

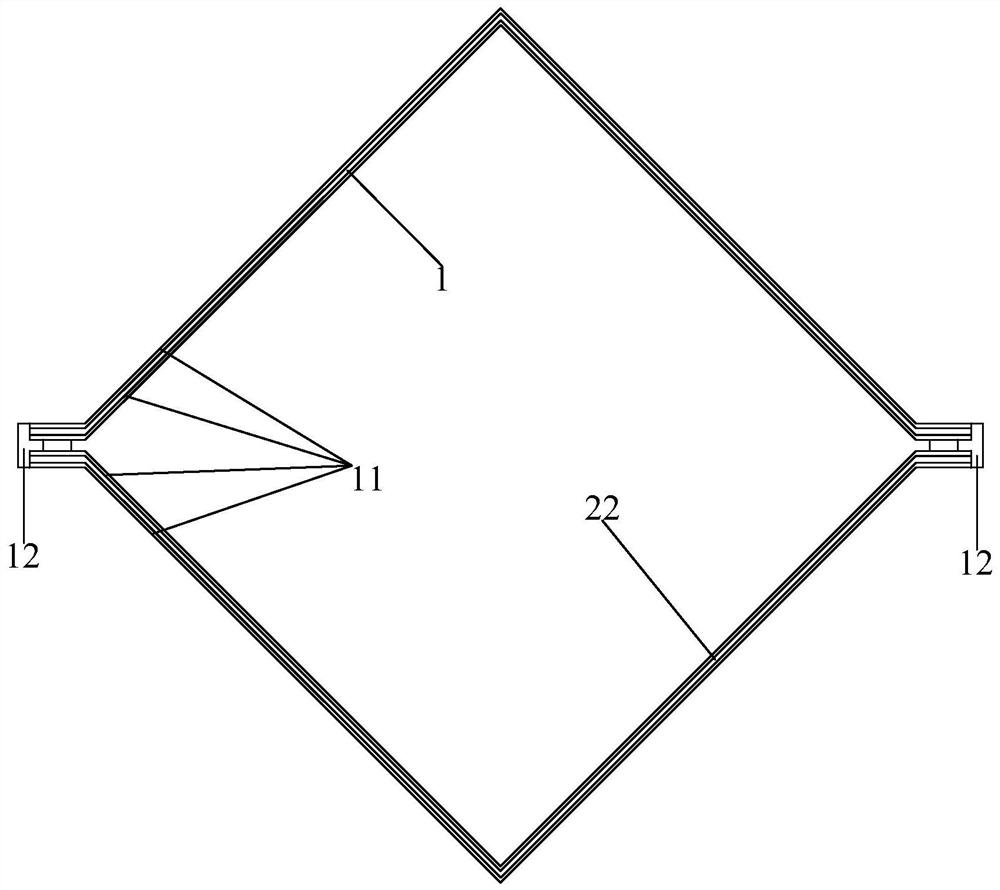

[0022] Such as Figure 1-8 As shown, the present invention provides a variable-diameter straw, which consists of two deformable pieces 1 joined together to form a pipe body 10, and the middle part of the deformable piece 1 is an easily deformable region 2 that is squeezed to control the change of the pipe diameter. When designing a variable-diameter straw, it is an important consideration to prevent the shrinkage of the straw body during use after the straw is deformed. The reason for the retraction and deformation of the straw is that when the liquid is sucked, the suction force inside the straw is uneven.

[0023] The general design is to put the suction pipe on the ring to prevent the suction pipe from retracting and deforming. But in the actual use process, the suction force that the straw bears is not large. In this case, the variable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com