Retractable straw

A telescopic straw and tube technology, applied in the field of straws, can solve the problems of wasting materials, polluting the environment, unfavorable environmental protection, etc., and achieves the effects of convenient use and storage, reducing environmental pollution, and ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

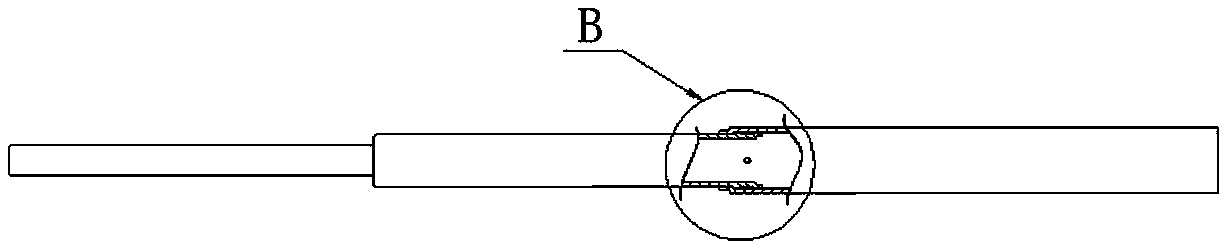

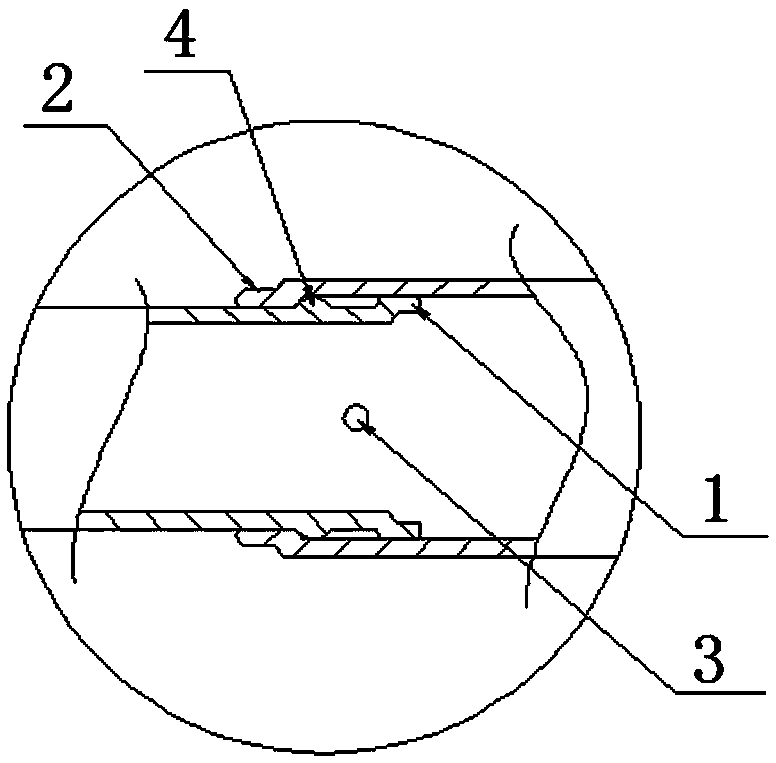

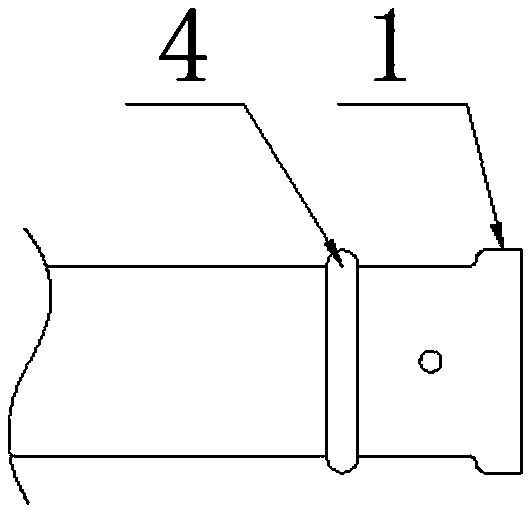

[0020] Embodiment 1: as figure 1 , figure 2 As shown, a telescopic straw is formed by socketing three stainless steel pipes arranged in increasing or decreasing diameters, the inner and outer pipes can be pulled out or retracted, and a connecting structure is provided at the joint of two adjacent pipes. The connection structure is that the end of the pipe with a small diameter at the connecting end of the adjacent pipe is provided with a length of 4 mm convex pipe 1, and a circle of convex ring 4 is provided at a distance of 6 mm from the convex pipe 1 (such as image 3 As shown), the convex tube 1, the convex ring 4 and the pipe are integrated structure, the outer diameter of the convex tube 1, the convex ring 4 is matched with the inner diameter of the pipe that is socketed; the diameter of the connecting end of the adjacent pipe is large The end of the pipe is provided with a necking section 2 (such as Figure 4 As shown), the inner diameter of the necking section 2 is m...

Embodiment 2

[0021] Embodiment 2: as Figure 6 , Figure 7 As shown, another telescopic straw is formed by socketing 4 stainless steel pipes arranged in increasing or decreasing diameters. The inner and outer pipes can be pulled out or retracted. The connection structure described above is that only a section of convex pipe 1 with a length of 7 mm is provided at the end of a pipe with a small diameter adjacent to the connection end of the pipe. Others are the same as in Example 1.

Embodiment 3

[0022] Embodiment 3: Another telescopic straw is formed by socketing 5 stainless steel pipes arranged in increasing or decreasing diameters, the inner and outer pipes can be pulled out or retracted, and a connecting structure is provided at the junction of two adjacent pipes. The connection structure is that a section of the adjacent pipe with a smaller diameter is provided with a convex pipe 1 with a length of 6 mm, and a ring of convex ring 4 is provided at a distance of 7 mm from the convex pipe 1 . Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com