Full biodegrade straw sucker and preparation method thereof

An all-biological, straw-based technology, applied in the field of all-biodegradable straw straws and its preparation, can solve the problems of complex preparation process, non-degradable straws, incomplete degradation, etc., and achieve the effects of simple preparation process, safe use, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

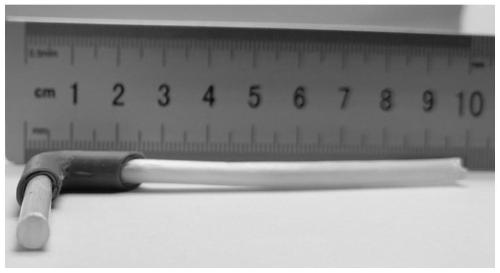

[0028] The preparation method of the fully biodegradable straw straw of this embodiment includes:

[0029] (1) Straw pretreatment

[0030] The harvested straws are air-dried, and after drying, the straws are de-knotted to leave a tubular part. The obtained straw tube is subjected to lignin removal and bleaching, and the straw tube is soaked in a mixed aqueous solution of glacial acetic acid and sodium chlorite with a molar ratio of 1.5:1 until the straw tube turns white. Then wash with distilled water until the filtrate is neutral, and then dry the straw tube at 105°C to a constant weight.

[0031] (2) Preparation of straw tube

[0032] Soak the pretreated straw tube in a cellulose solution with a concentration of 5wt% for 1 hour, then take it out to condense in the air for 3.5 hours to form a cellulose colloid on the surface of the straw tube, and then place the straw tube in distilled water for 4 days. The solvent is air-dried to obtain a straw straw. Among them, the cellulose so...

Embodiment 2

[0036] The preparation method of the fully biodegradable straw straw of this embodiment includes:

[0037] (1) Straw pretreatment

[0038] The harvested straws are air-dried, and after drying, the straws are de-knotted to leave a tubular part. The obtained straw tube is subjected to lignin removal and bleaching, and the straw tube is soaked in a mixed aqueous solution of glacial acetic acid and sodium chlorite with a molar ratio of 1.2:1 until the straw tube turns white. Then wash with distilled water until the filtrate is neutral, and then dry the straw tube at 90°C to a constant weight.

[0039] (2) Preparation of straw tube

[0040] Soak the pretreated straw tube in a cellulose solution with a concentration of 1wt% for 0.5h, then take it out to condense in the air for 2.5h to form a cellulose colloid on the surface of the straw tube, and place the straw tube in distilled water for 2 days The solvent is exchanged, and the straw straw is obtained after natural air drying. Among th...

Embodiment 3

[0044] The preparation method of the fully biodegradable straw straw of this embodiment includes:

[0045] (1) Straw pretreatment

[0046] The harvested straws are air-dried, and after drying, the straws are de-knotted to leave a tubular part. The obtained straw tube is subjected to lignin removal and bleaching, and the straw tube is soaked in a mixed aqueous solution of glacial acetic acid and sodium chlorite with a molar ratio of 1.4:1 until the straw tube turns white. Then wash with distilled water until the filtrate is neutral, and then dry the straw tube at 100°C to a constant weight.

[0047] (2) Preparation of straw tube

[0048] Soak the pretreated straw tube in a cellulose solution with a concentration of 3wt% for 45 minutes, then take it out to condense in the air for 3 hours to form a cellulose colloid on the surface of the straw tube, and then place the straw tube in distilled water for 3 days to exchange the solvent , And get straw straws after natural air drying. Amon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com