Suction and release double paper mechanism of sticky handle paper cup forming machine

A technology of forming machine and paper sheet, applied in the direction of cardboard articles, etc., can solve the problems of cumbersome production process, increase production cost, etc., and achieve the effects of reducing cost burden, solving the problem of hot hands, and improving production efficiency and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

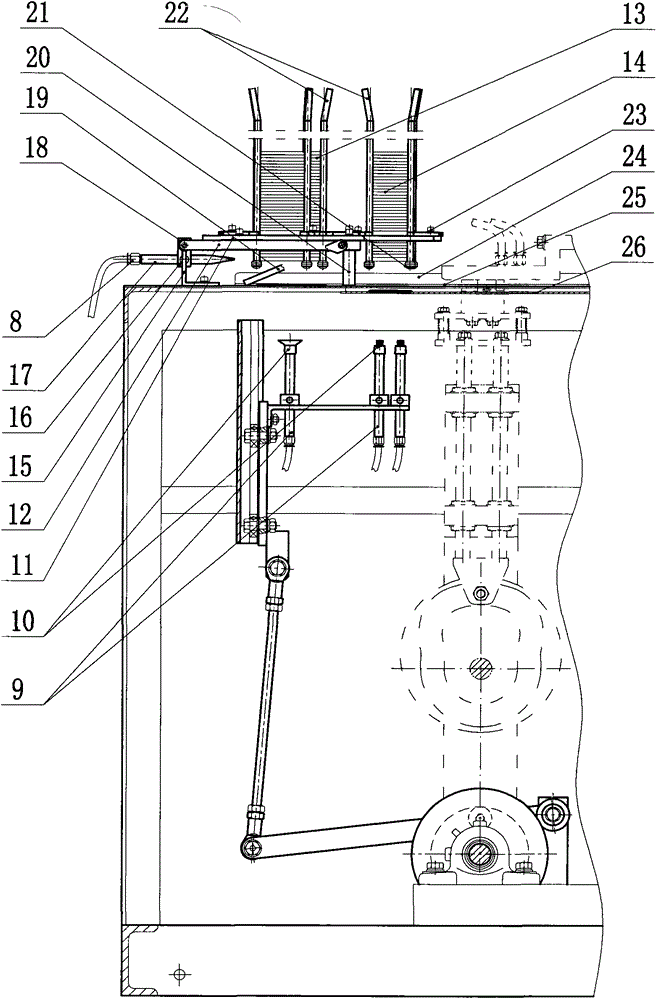

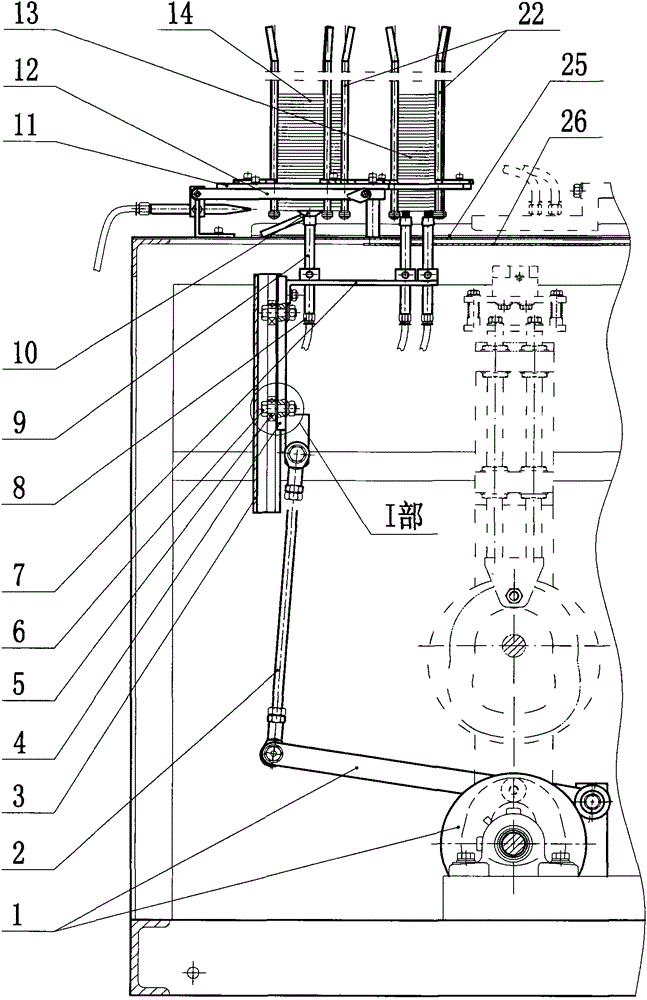

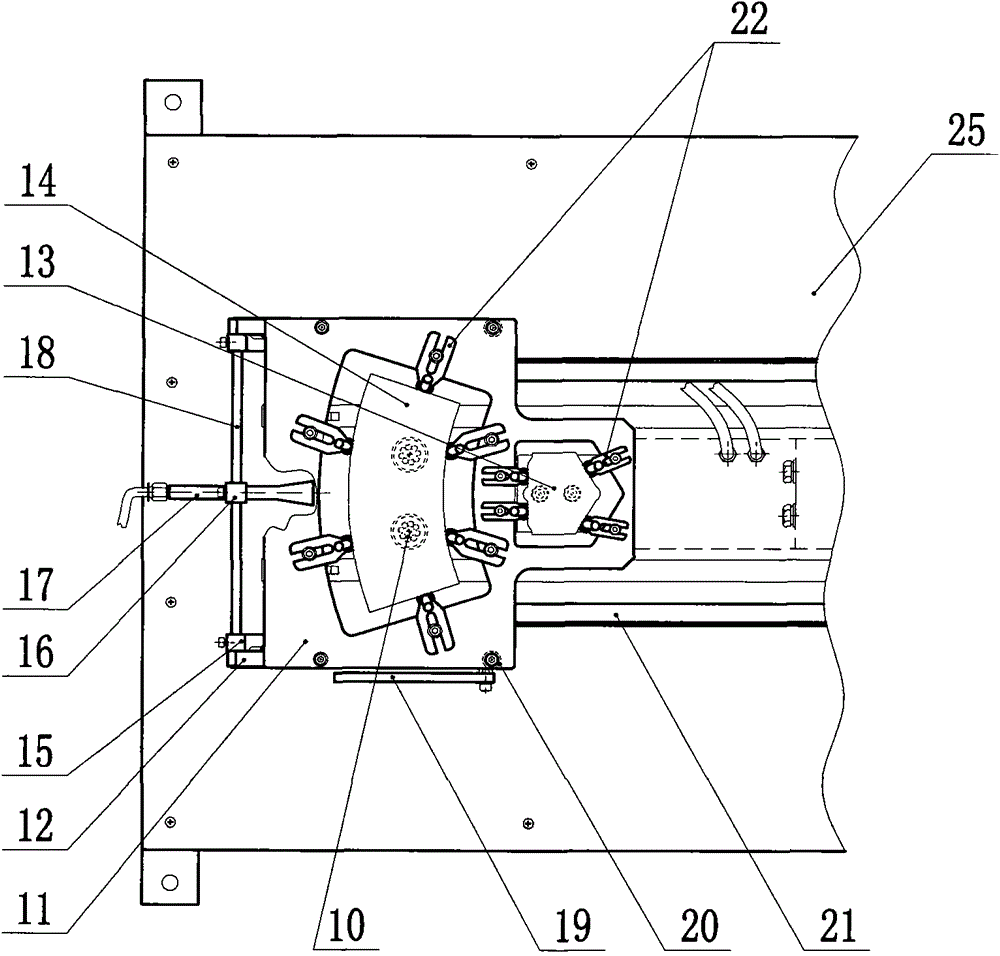

[0016] The present invention will be further described below in conjunction with accompanying drawing embodiment:

[0017] The technical solution adopted in the present invention is: the suction and release double paper mechanism of the sticky handle type paper cup forming machine is composed of a suction and release structure for sucking and releasing paper sheets and a stacking structure for stacking paper sheets. The rod transmission mechanism 1 is connected to the connecting rod 2, and the connecting rod moves upward to connect the slide plate 4, the roller 5 and the shaft pin 6, and the slide plate 4 is connected upwardly to the pipe seat 7, the suction pipe 9 and the suction nozzle 10, and the gas delivery pipe is connected to each suction pipe 9 through the pipe joint 8 , A paper holder plate 11 is provided above the suction nozzle 10 . The inner hole of the roller 5 is connected to the slide plate 4 through the shaft pin 6, and the roller 5 is slidably connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com