Compressed straw sustained-release fertilizer planting device covered with knitting bag load-bearing container

A woven bag and slow-release fertilizer technology, which is applied in organic fertilizers, forestry, cultivation, etc., can solve the problems of less active ingredients and large volume, and achieve the effects of reducing nursing intensity, good air permeability, and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

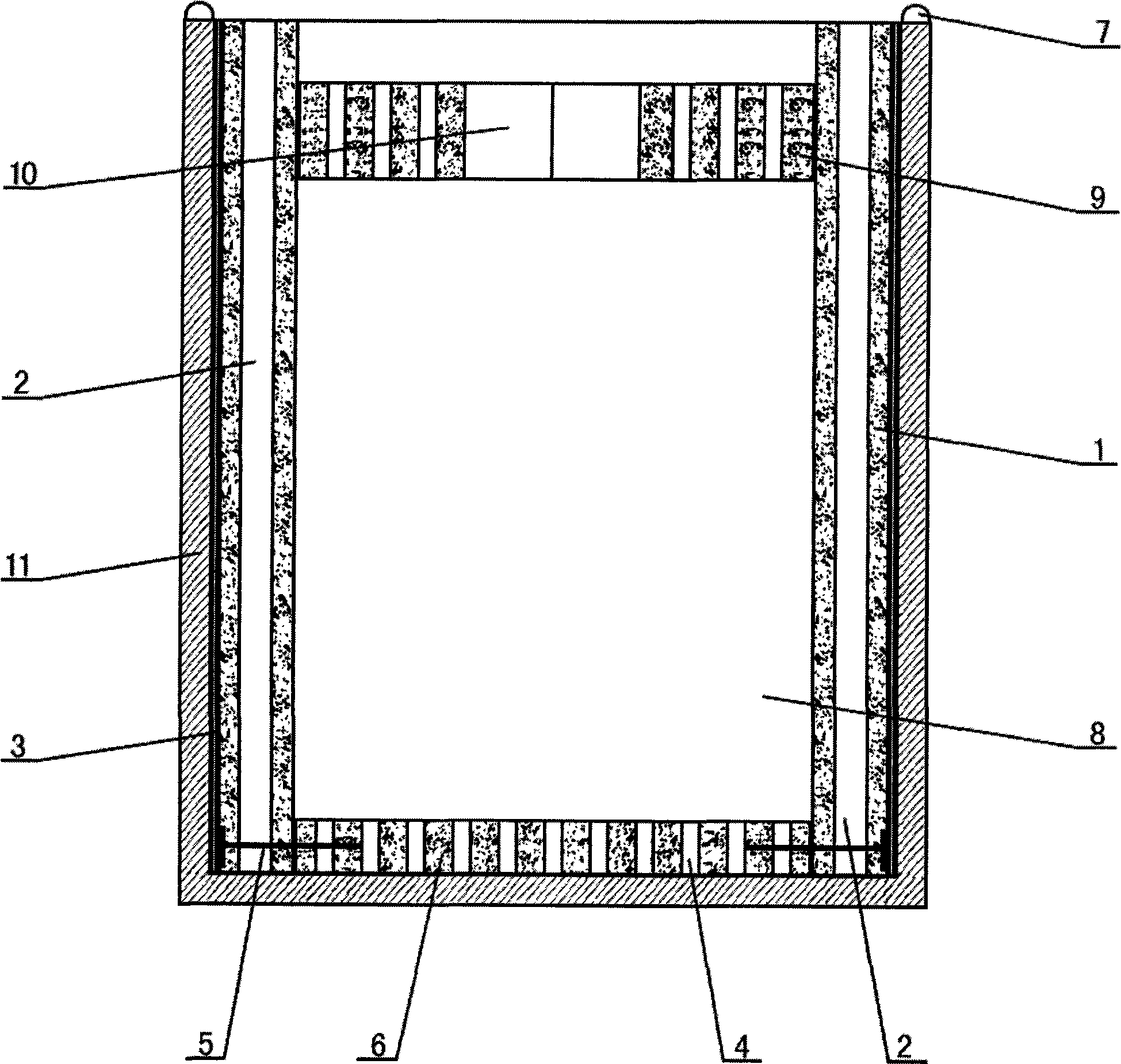

[0029] Such as figure 1 Shown: the compacted straw block material 1 is provided with vertical air vent 2, and the compressed straw block material 1 is combined to form a straw tube, and the bottom of the straw tube is provided with a straw bottom 6 made of compressed straw, Straw bottom 6 is provided with ventilation hole 4, and the compression straw block material 1 is positioned and fixed with straw bottom 6 by positioning nail 5, and the top of tube rod tube is equipped with the straw cover 9 that stalk is made through compression, Straw cover 9 is provided with air vent 4 and plant growth hole 10. The longitudinal outer wall of straw tube is compounded with plastic film 3 and suit woven bag 11, and the upper end of woven bag 11 is provided with lifting lug 12.

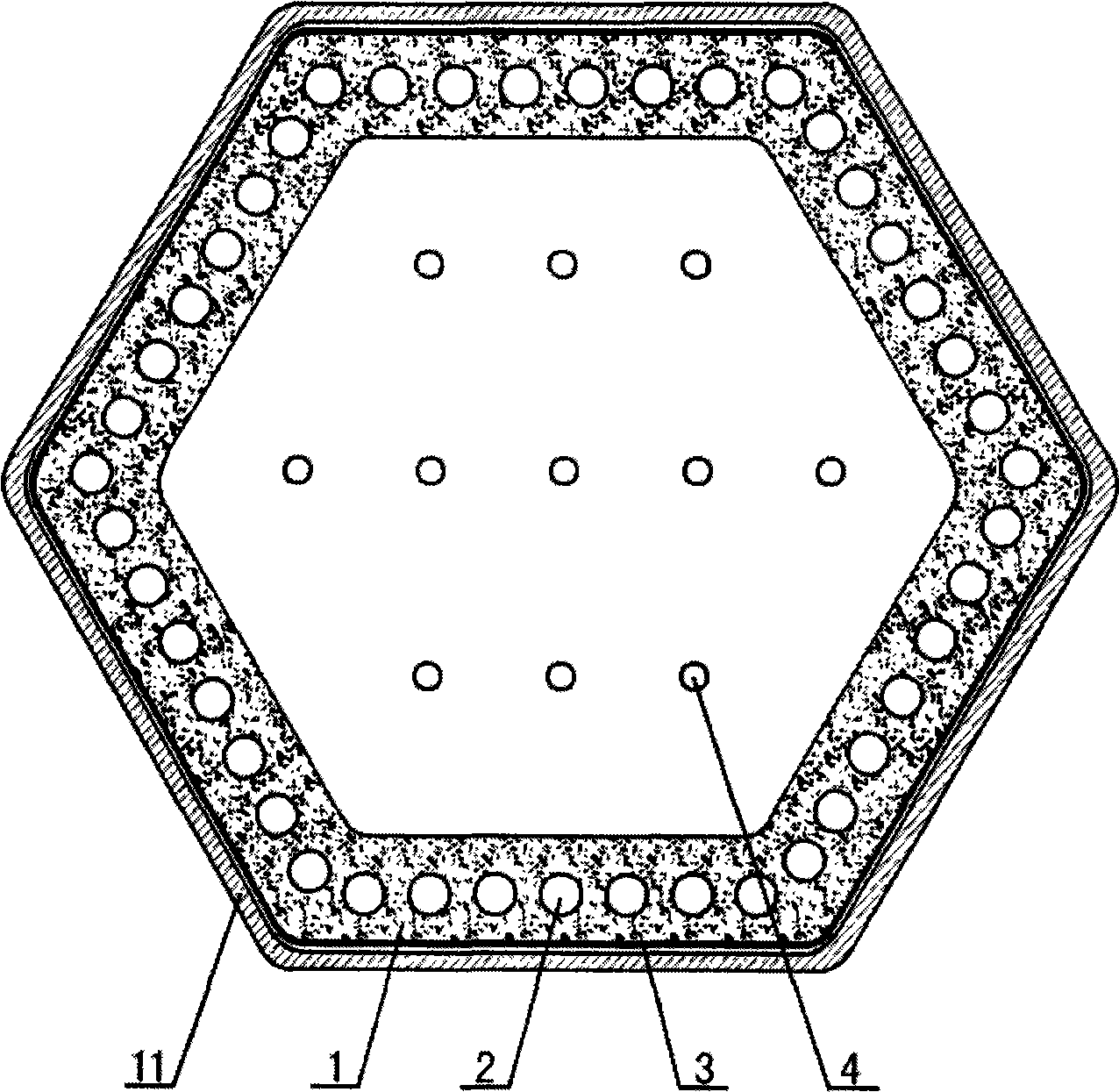

[0030] Such as figure 2 Shown: compress the stalk block material 1 once and extrude into the hexagonal stalk tube, others are equal to figure 1 .

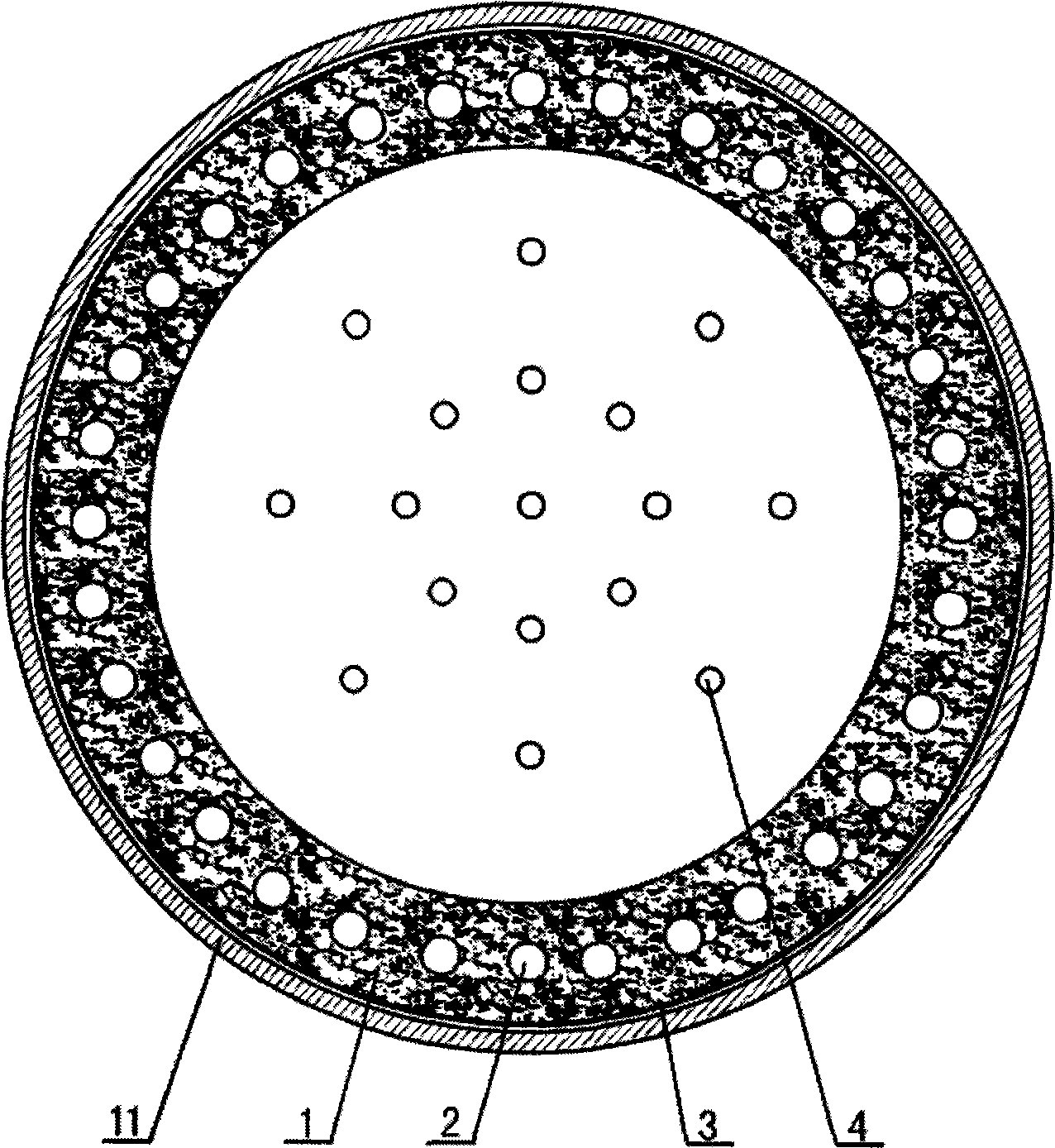

[0031] Such as image 3 Shown: compress the stalk block mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com