A cellulose raw material preservative device that can save preservative liquid

A kind of preservative device, cellulose technology, applied in wood treatment details, reed/straw treatment, wood impregnation, etc., can solve the problems of difficult transfer of straw, difficult cleaning of residual liquid, insufficient anti-corrosion strength, etc., and achieve the effect of difficult transfer of straw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

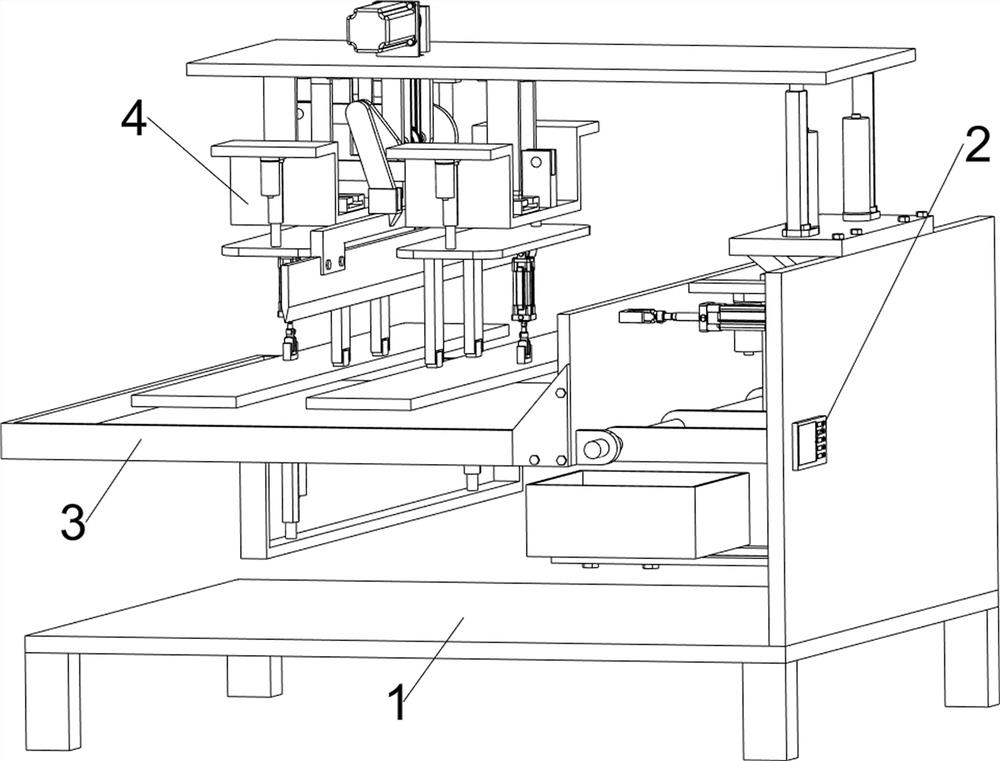

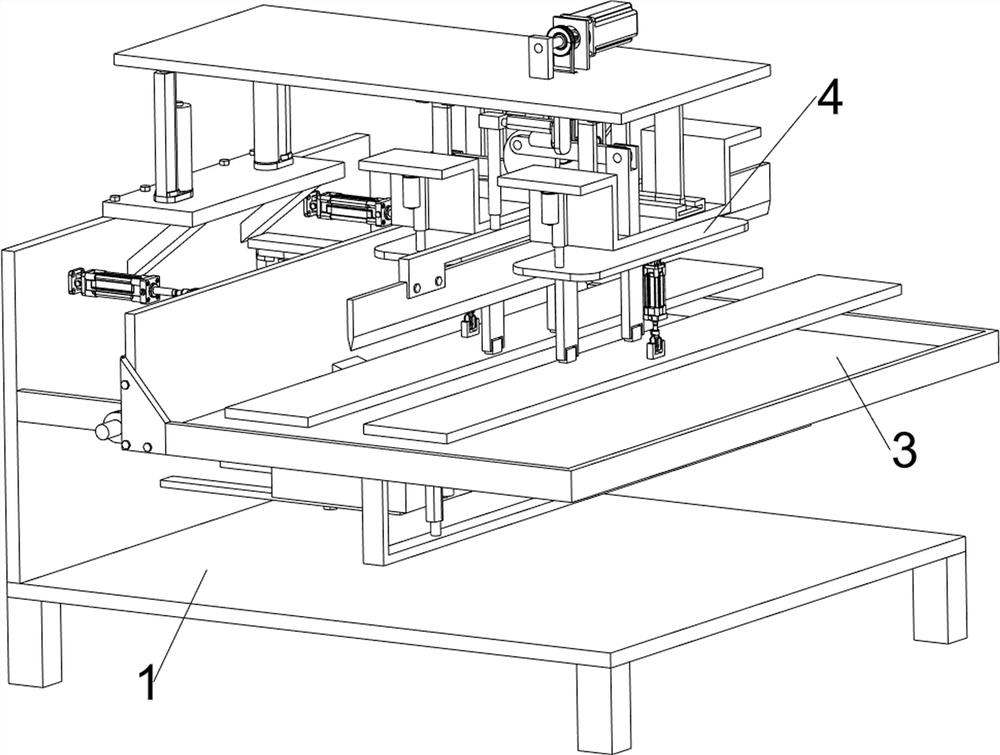

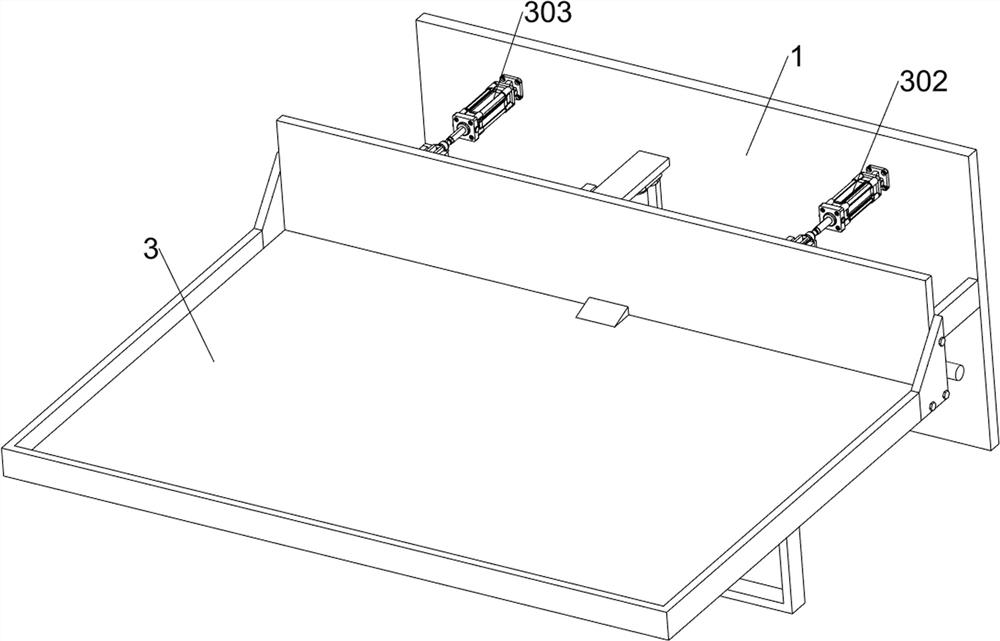

[0100] A cellulose raw material preservative device that can save preservative liquid, such as Figure 1-15 As shown, it includes a support frame 1, a control panel 2, a controllable tilt system 3 and a cut-off dislocation system 4; the support frame 1 is used for the support device; the control screen 2 is connected with the support frame 1; the controllable tilt system 3 is connected with the support frame 1 is connected; cut off the dislocation system 4 is connected with the support frame 1.

[0101] Working process: When using this device, first install the device horizontally in the place to be used, and the device is in a position where it is convenient to sprinkle antiseptic liquid, then connect the power supply, turn on the control panel 2 to control the operation of the device, and place the prepared straws. The raw material straw pipes are placed near the device, the straw pipes are cut and trimmed on both sides, and then an appropriate amount of straw pipes are put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com