A detackification device for a pharmaceutical pulverizer

A pulverizer and equipment technology, applied in the direction of grain processing, etc., can solve the problems of mixing, drug powder dirt, etc., and achieve the effect of avoiding powder raising

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

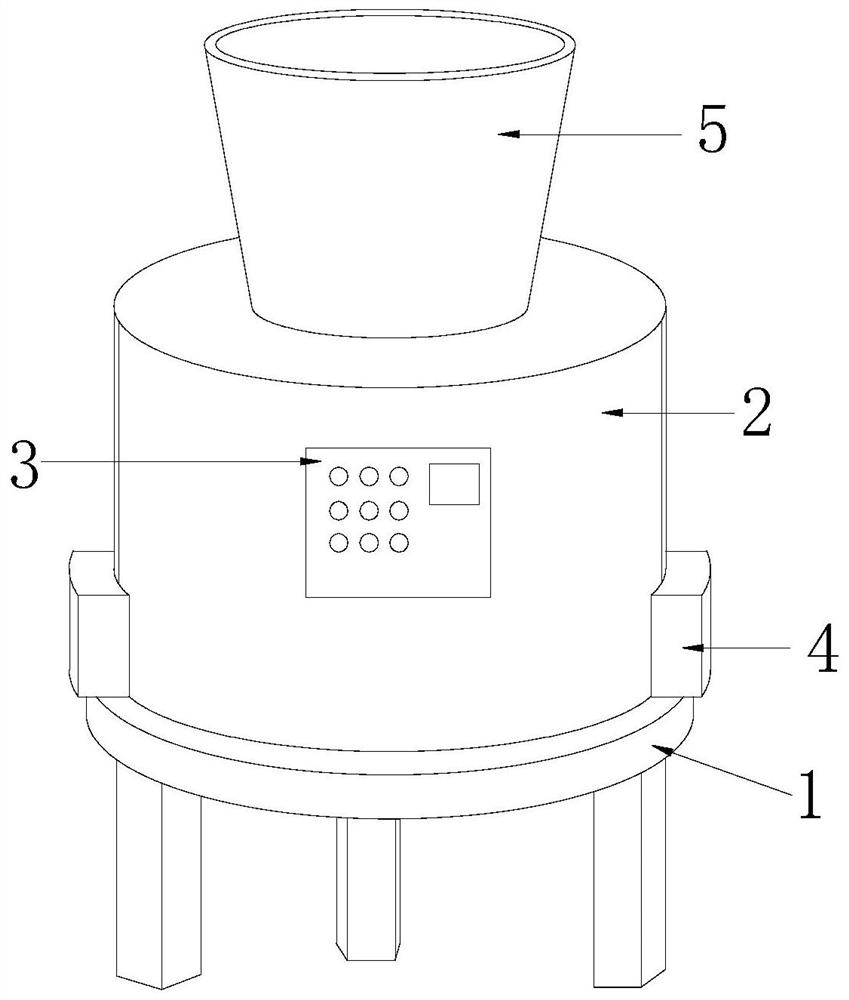

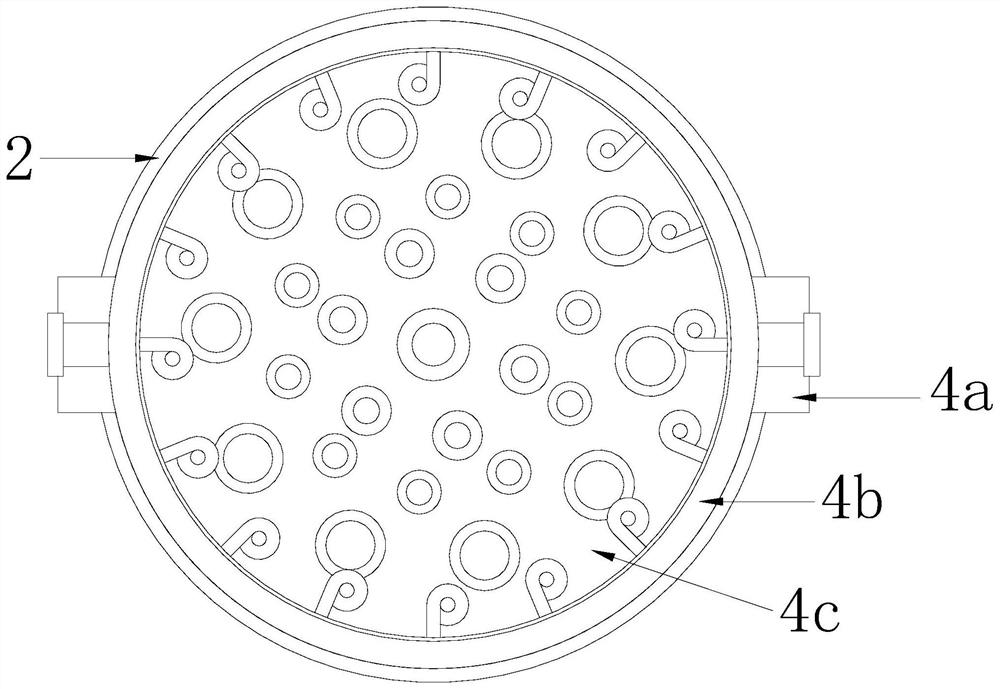

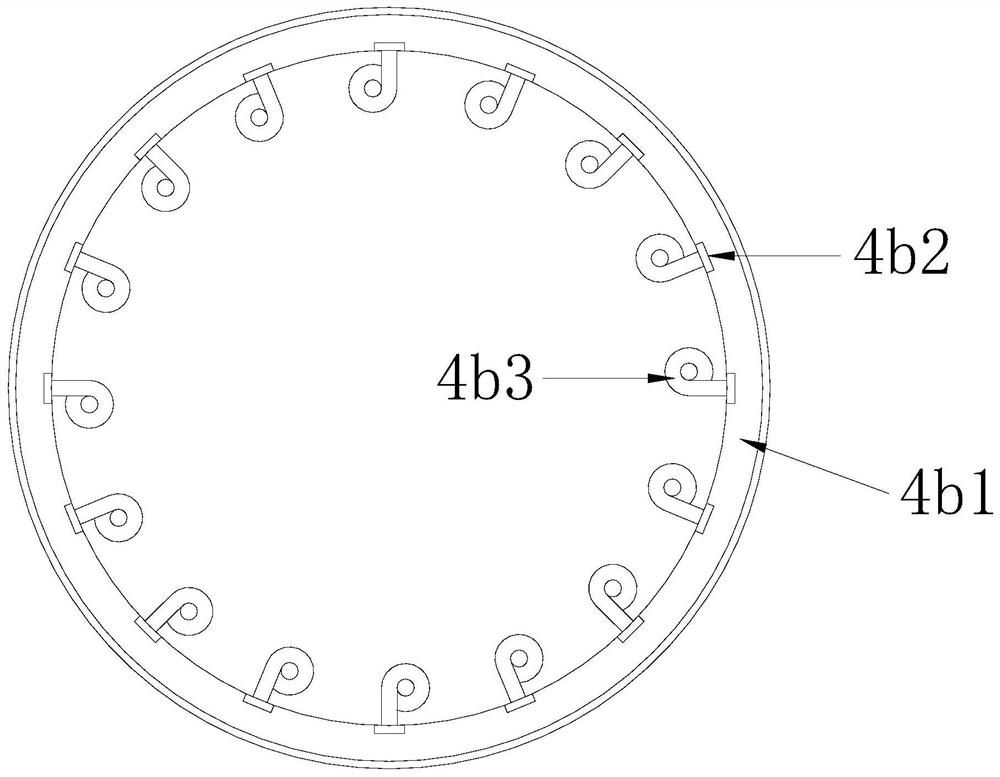

[0029] Such as Figure 1-Figure 5 As shown, the present invention provides a technical scheme of a detackification equipment for a pharmaceutical pulverizer:

[0030] Such as Figure 1-Figure 2 As shown, a debonding equipment for a pharmaceutical pulverizer has a structure including a bracket 1, a pulverizing cylinder 2, a controller 3, an adhesion suppression device 4, and a feed hopper 5. The pulverizing cylinder 2 is installed on the upper surface of the bracket 1, and the The controller 3 is arranged on the front surface of the crushing cylinder 2 and is electrically connected, the attachment suppression device 4 is arranged on the inside of the crushing cylinder 2 and cooperates, and the feeding hopper 5 is arranged on the upper surface of the crushing cylinder 2 and connected through each other. The attachment device 4 includes a power device 4a, a stroke removal structure 4b, and a suction mechanism 4c. There are two power devices 4a and they are respectively symmetric...

no. 2 example

[0040] Such as Figure 6-Figure 7 As shown, the present invention provides a technical scheme of a detackification equipment for a pharmaceutical pulverizer:

[0041] Such as Figure 6-Figure 7 As shown, a debonding equipment for a pharmaceutical pulverizer, its structure includes the suction mechanism 4c including a cavity 4c1, a sticky strip 4c2, an adsorption net 4c3, and a sleeve hole 4c4, and the inner bottom of the cavity 4c1 is evenly distributed with sticky Bar 4c2, the adsorption net 4c3 is arranged on the upper surface of the nanocavity 4c1 and is an integrated structure, and the set of holes 4c4 are evenly distributed on the surface of the adsorption net 4c3 and cooperate with each other, which is beneficial to realize concentrated absorption of the medicine powder.

[0042] Such as Figure 6-Figure 7 As shown, a suction pump is provided inside the cavity 4c1, the cavity 4c1 is a retractable structure, and the surface mesh of the adsorption net 4c3 is a single-entry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com