Laser and ultrasound combined type drilling system and machining method thereof

A processing system and ultrasonic processing technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of damaged material quality, low processing surface precision, and inability to complete drilling, etc., to improve surface processing accuracy, Improve the surface accuracy of the workpiece and protect the quality of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

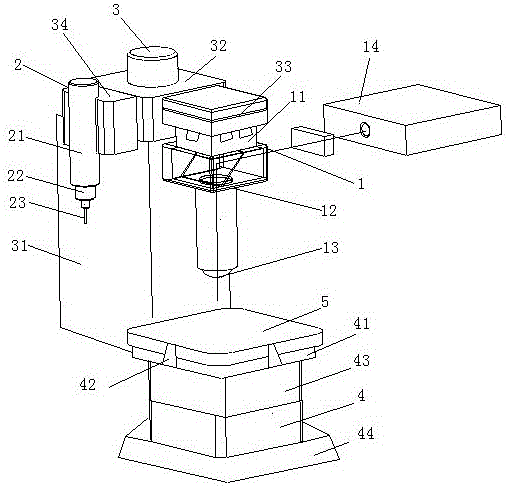

[0029]A laser and ultrasonic composite drilling processing system, the processing system mainly includes a laser processing system 1, an ultrasonic processing system 2, a precision rotary positioning mechanism 3 and an axis alignment system 4, the laser processing system 1 and the ultrasonic processing system 2. By installing on the precision rotary positioning mechanism 3 to regulate and control the positioning;

[0030] The laser processing system 1 mainly includes a support top 11, a laser component mounting seat 12, a laser working component 13, a laser exciter 14 and a laser control terminal. The laser component mounting seat 12 is fixedly installed under the support top 11, and the interior is The shielded working cavity of the laser working part 13 is installed, and the laser working part 13 is mainly composed of the first condenser lens, the second condenser lens, a positive reflector, a secondary reflector, and a laser drilling hole positioned by a positioning adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com