View screen self-guiding type machined part burr removing machine

A deburring and self-guided technology, which is applied in the direction of machine tools, metal processing equipment, and workpiece feed movement control suitable for grinding workpiece edges, and can solve the problem of affecting the size of parts, losing luster on the surface of parts, and increasing processing costs, etc. To solve the problem, achieve the effect of high surface machining accuracy, shortening the cutting time, and precise and controllable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

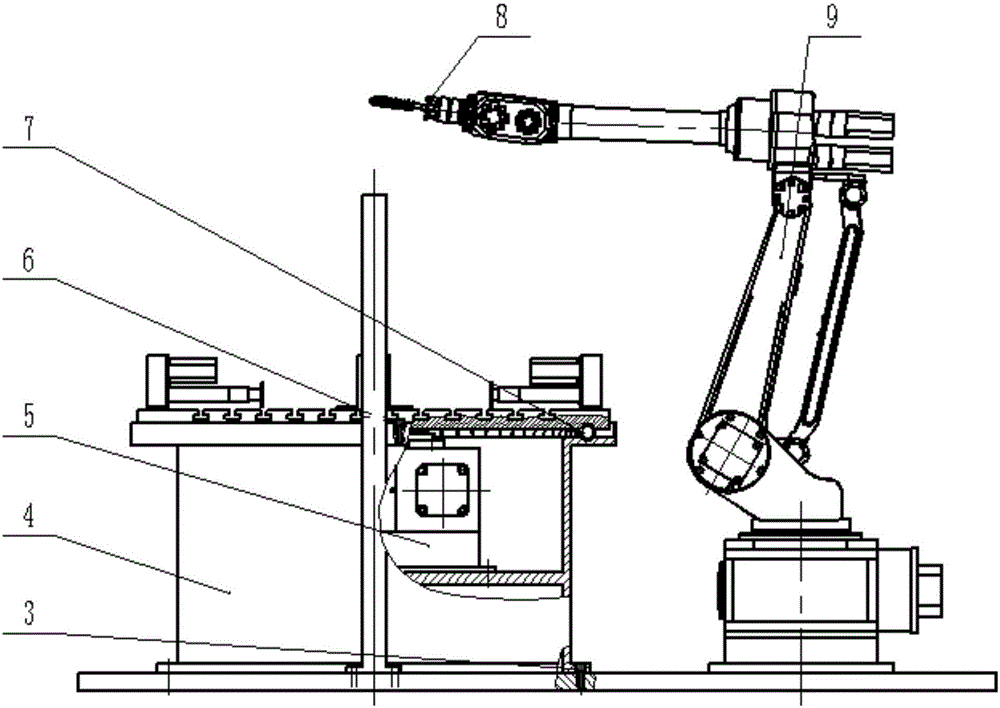

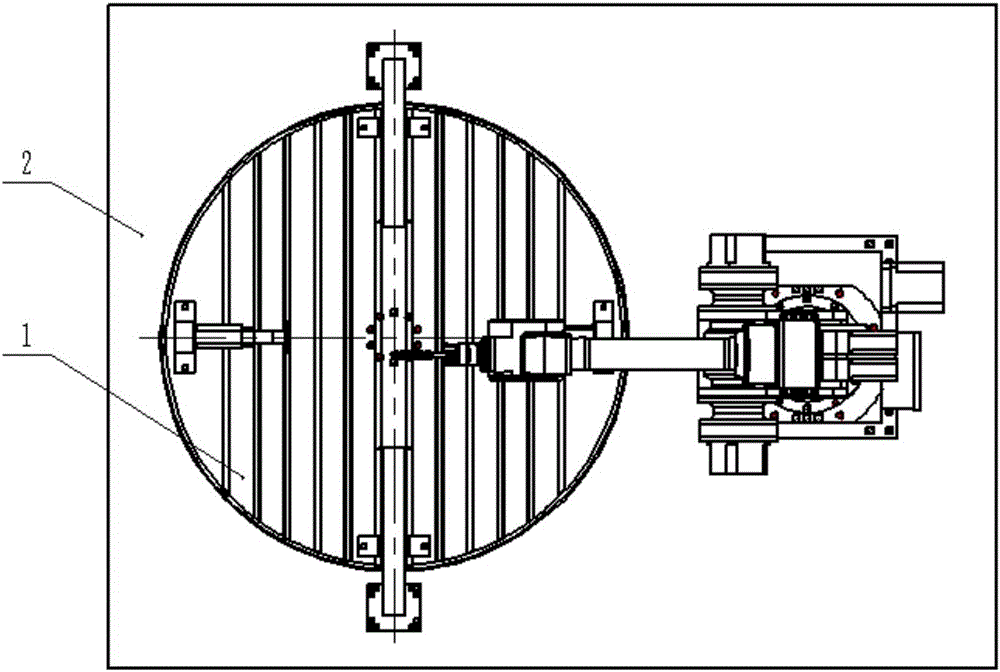

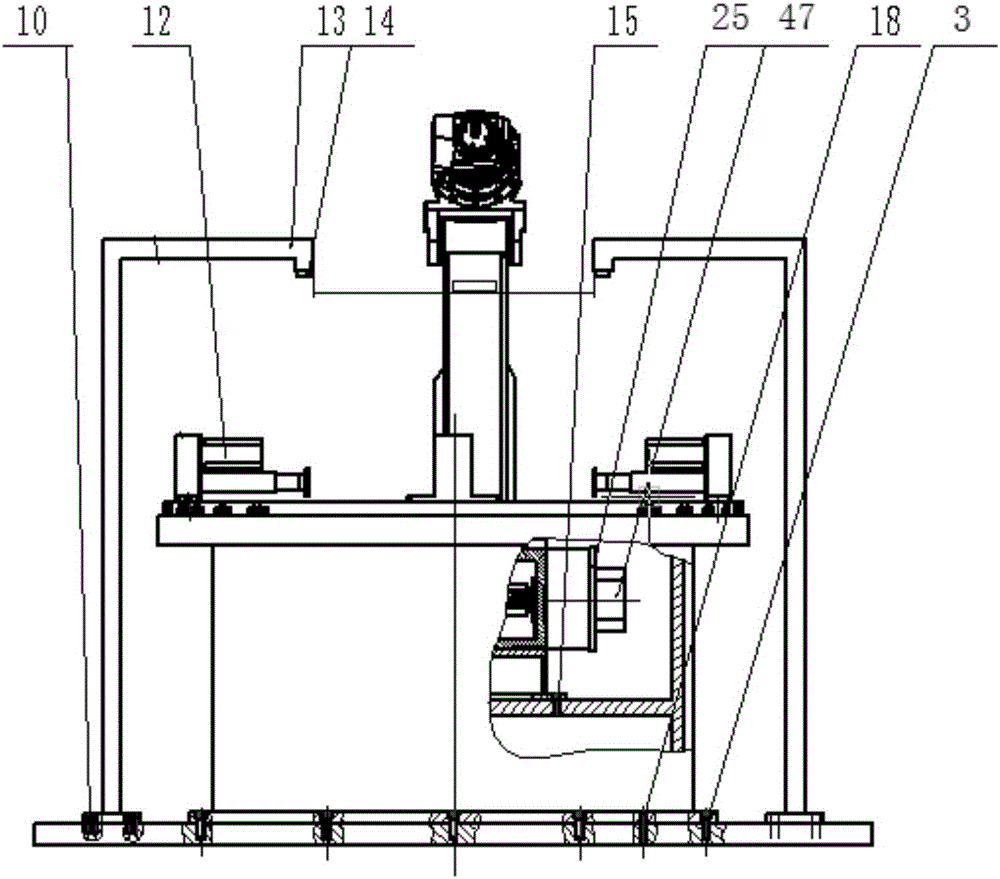

[0018] see Figure 1-6 , The video screen self-guided workpiece deburring machine of the present invention consists of a base 4, a rotating part 5, a sensor assembly 6, a workbench assembly, a magnetic needle cutter assembly, and mechanical arms 9 and other mechanisms. The base 4 is fixed on the ground 2 with bolts 3, and is used to carry rotating parts, workbench components and parts, etc. The base 4 is fixedly connected to the rotating part 5 by screws 15 . The mechanical arm 9 is fixed on the ground 2, and the magnetic needle cutter assembly is housed on the mechanical arm 9.

[0019] The rotary part 5 also includes a small electric box cover 25, a small electric box 26, a worm motor flange 27, a deep groove ball bearing 28, a flat key 29, a worm screw 30, a worm screw bearing flange 33, a rotary base 34, a retaining ring 35, Deep groove ball bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com