Roll workpiece surface grinding and polishing all-in-one machine

A workpiece surface and integrated machine technology, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., can solve the problem of high cost of roll processing, low efficiency of roll surface processing, and large volume of roll polishing equipment and other problems, to achieve the effect of simple structure, lower processing cost and lower equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

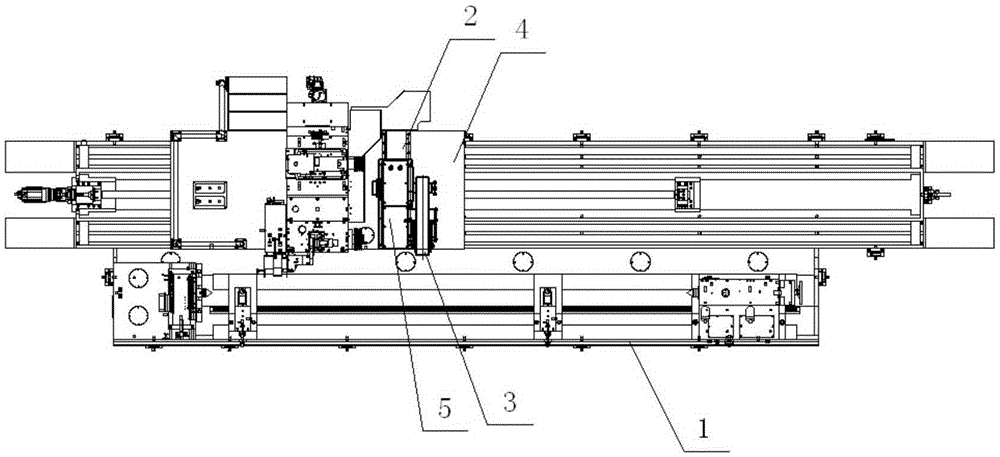

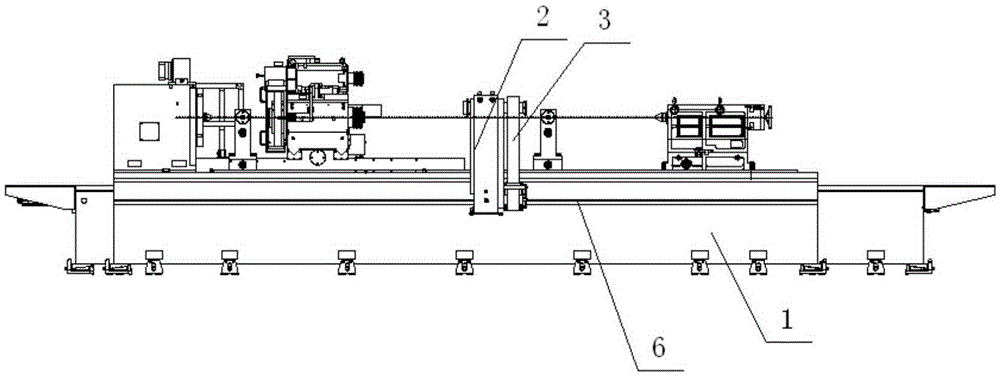

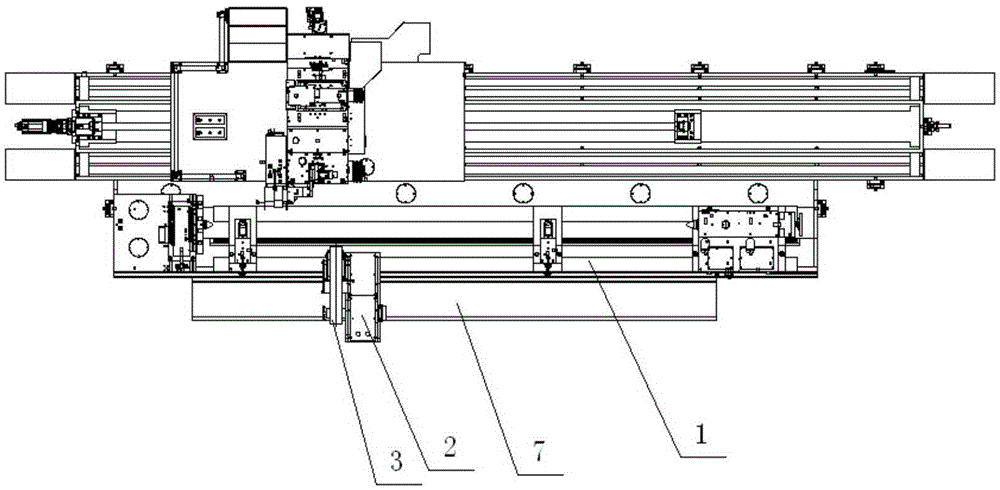

[0018] Embodiment: An integrated machine for grinding and polishing the surface of a roll workpiece, comprising a roll grinder 1, a polishing device 2, an axial drive device and a radial drive device 5, the polishing device 2 is installed on one side of the roll grinder 1, and the axial The driving device can drive the polishing device 2 to move axially along the roll, and the radial driving device can drive the polishing device 2 to feed radially along the roll. The polishing device 2 is provided with at least one polishing head 3, and the polishing head 3 can contact the roll grinder 1. roll surface.

[0019] The grinding process of the roll on the roll grinder 1 is completed without unloading, and the polishing device 2 is directly driven by the axial drive device and the radial drive device 5. On the roll grinder 1, the roll is fed along the axial and radial directions to realize the fineness of the roll surface. Polishing, the roll can be ground and finely polished by one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com