Electrochemical additive manufacturing method and device

A technology of electrochemical machining and chemical reaction, which is applied in the field of electrochemical manufacturing and additive manufacturing by electrochemical methods, namely three-dimensional printing. The effect of increased locality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

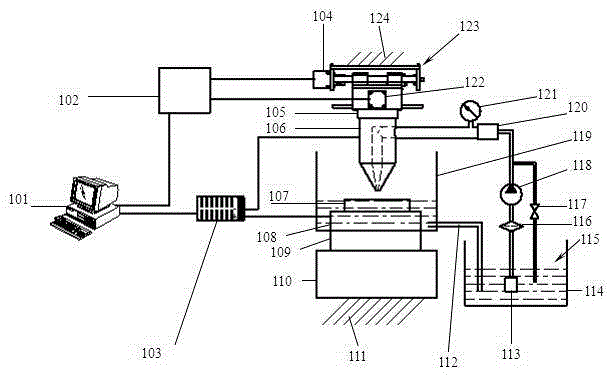

[0012] exist figure 1 , the computer (101) runs the control program, and sends instructions to the stepper motor driver (102) through the connecting cable, and the output of the stepper motor driver (102) is respectively connected to the X-axis stepper motor (104) and on the Y-axis stepper motor (123). The sliding table moving plate (122) is connected with the shower head (106) through the insulating connecting plate (105). The computer (101) runs the control program, and at the same time sends corresponding instructions to the programmable power supply (103) through the connecting cable, the negative output of the programmable power supply (103) is connected to the conductive pad (108), and the positive output is connected to the electrolyte nozzle (106 ). Electrical contact is maintained between the conductive pad (108) and the workpiece to be marked (107). The electrolyte pump (118) sucks the electrolyte (115) through the electrolyte inlet (113) and through the filter (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com