Machining electric spindle and numerical control machine tool

A technology of electric spindle and spindle, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of low precision, easy damage, complicated wiring, etc., achieve high precision, improve surface processing accuracy, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] CNC machine tool equipment manufacturing industry is the industrial machine tools, machining accuracy is an important indicator to evaluate its performance. When the spindle speed CNC machining complex parts are generally constant, and is sometimes due to the natural frequency of the vibration frequency of the cutting part coupling surface chatter marks generated, resulting in decreased surface quality, but also easy to form stress concentration areas, resulting in fatigue fracture of parts, which greatly reduces the complexity parts yield and service life. There are a displacement sensor by attaching the spindle to monitor abnormal vibration, to connect the CNC adaptive processing, the process efficiency is low, high precision, wiring complicated and easily damaged.

[0027] For this reason, the present embodiment provides a machining spindle, the higher the efficiency of the machining spindle, low accuracy, long life and easily damaged.

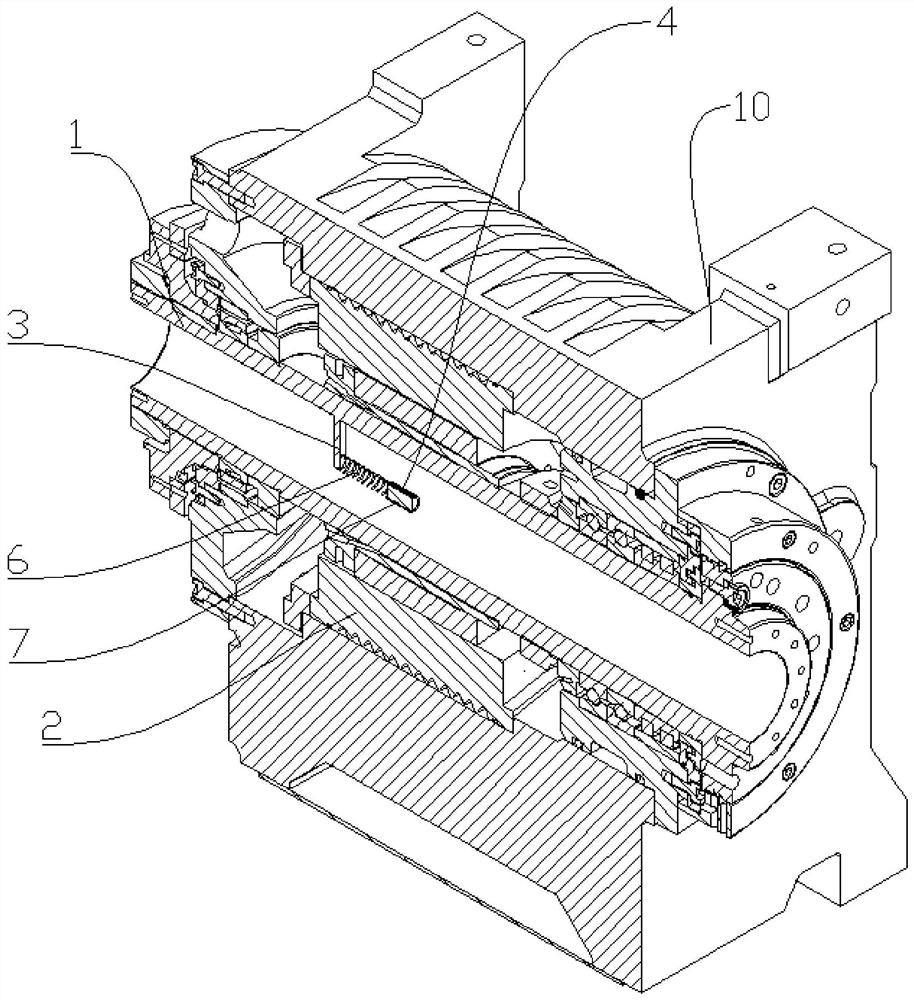

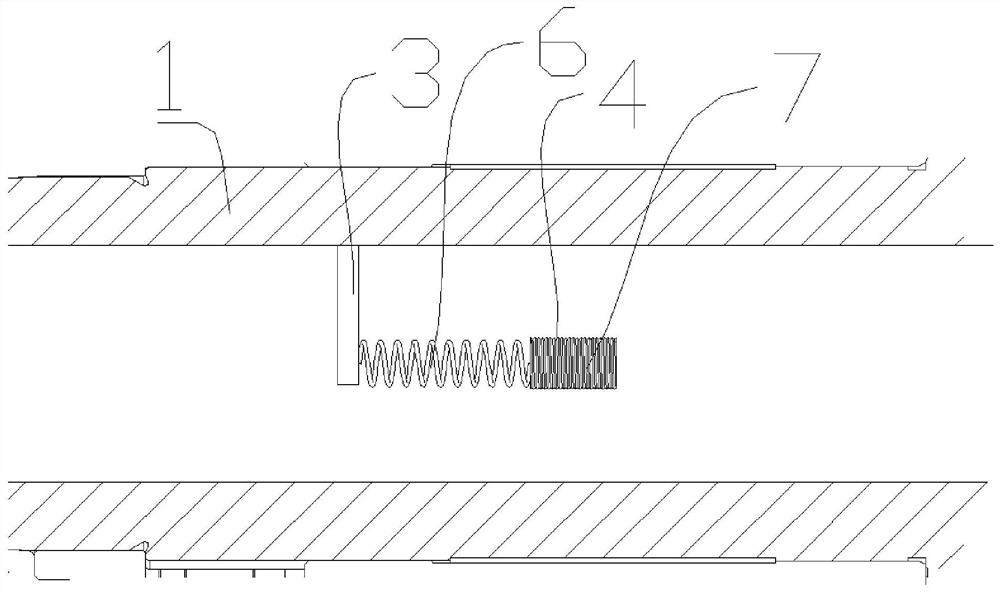

[0028] In one embodiment, such as...

Embodiment 2

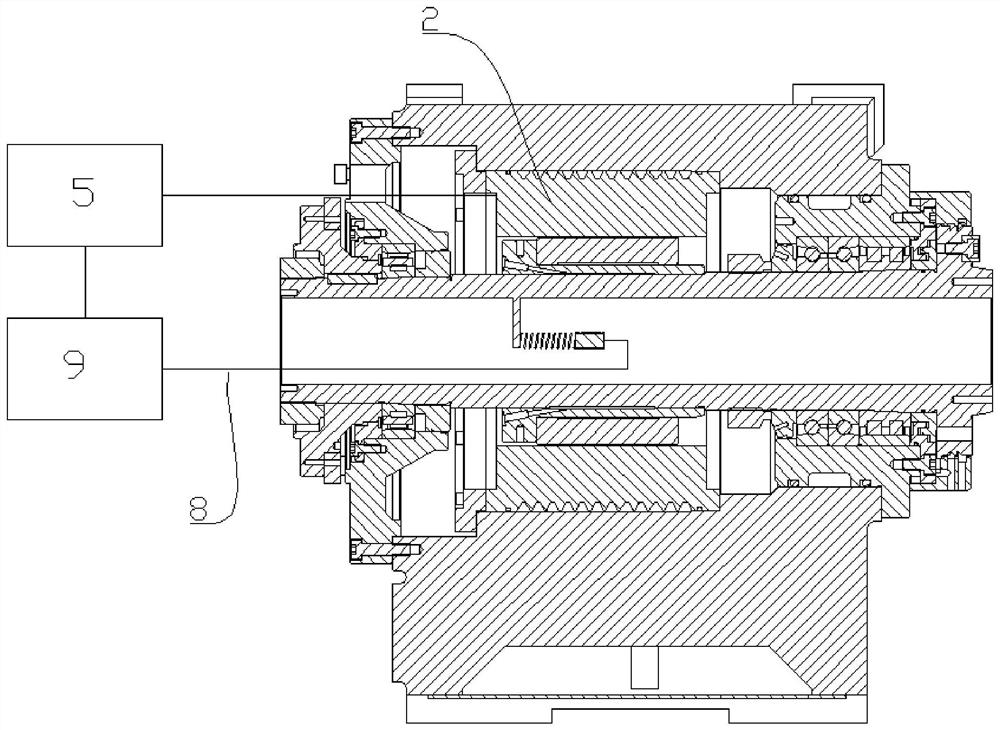

[0041] This embodiment provides a CNC machine tool, including the machining electrical spindle provided in the above embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com