Combined pneumatic machining fixture suitable for various shaft sleeves

A combined and multi-variety technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as difficulty in forming efficient market competitiveness, single type of fixture processing bushing, poor product quality stability, etc. Achieve the effects of easy processing, fast and convenient clamping, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

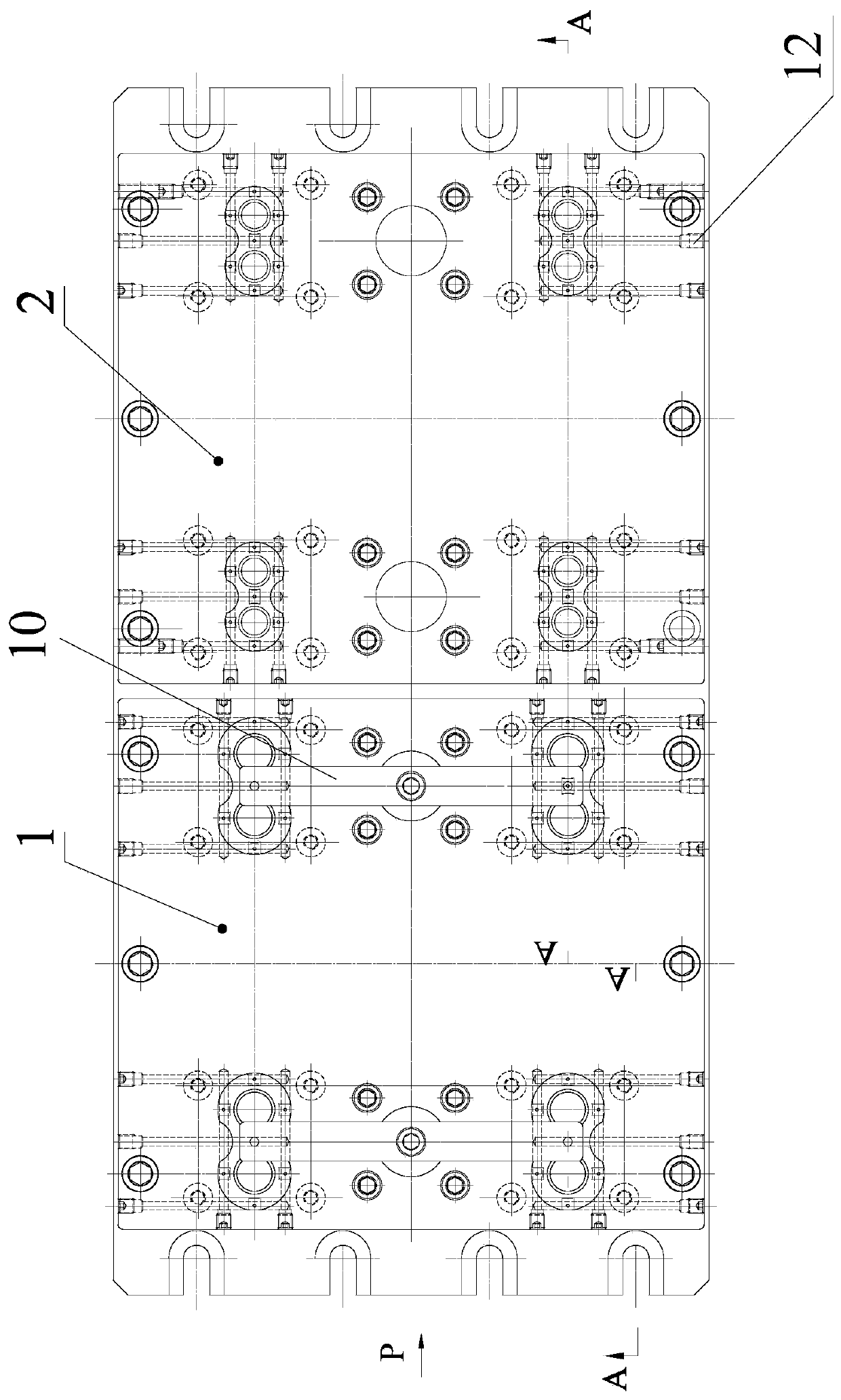

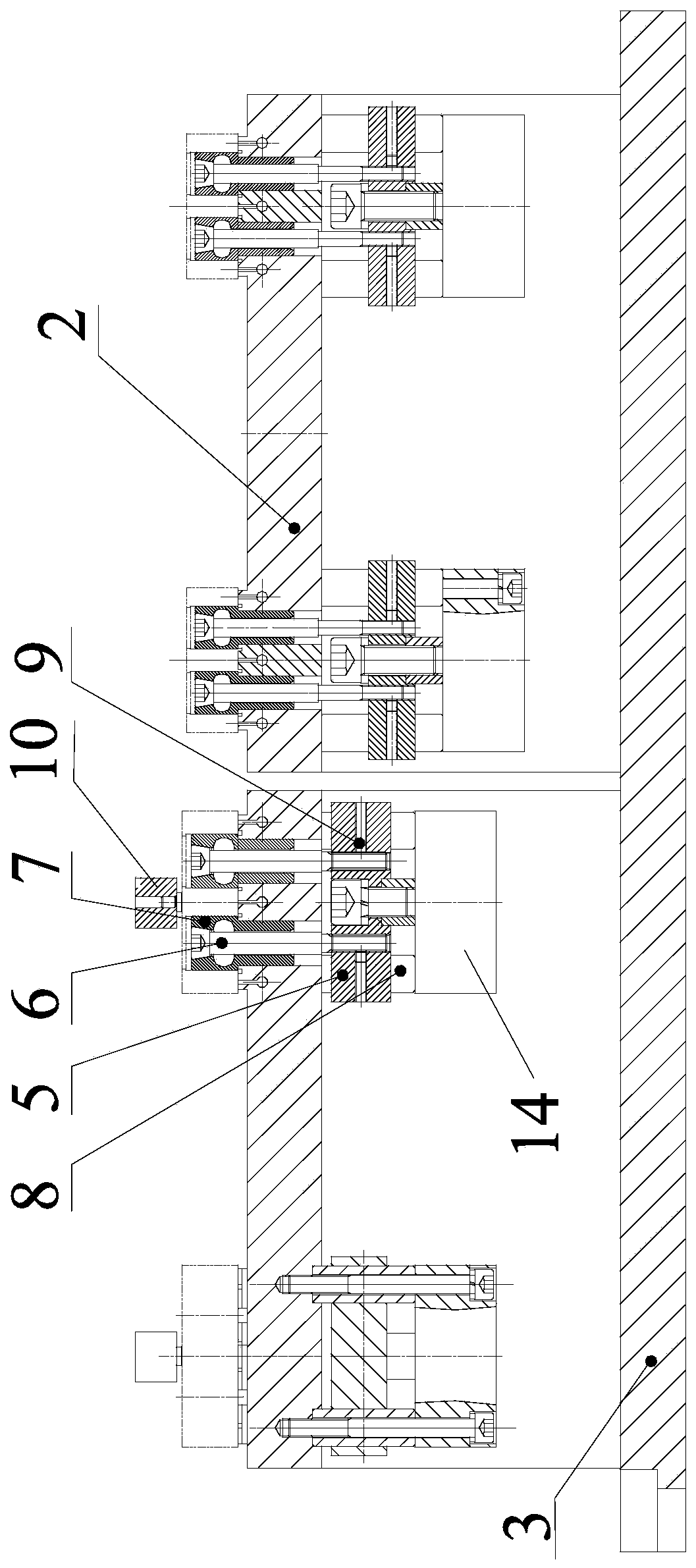

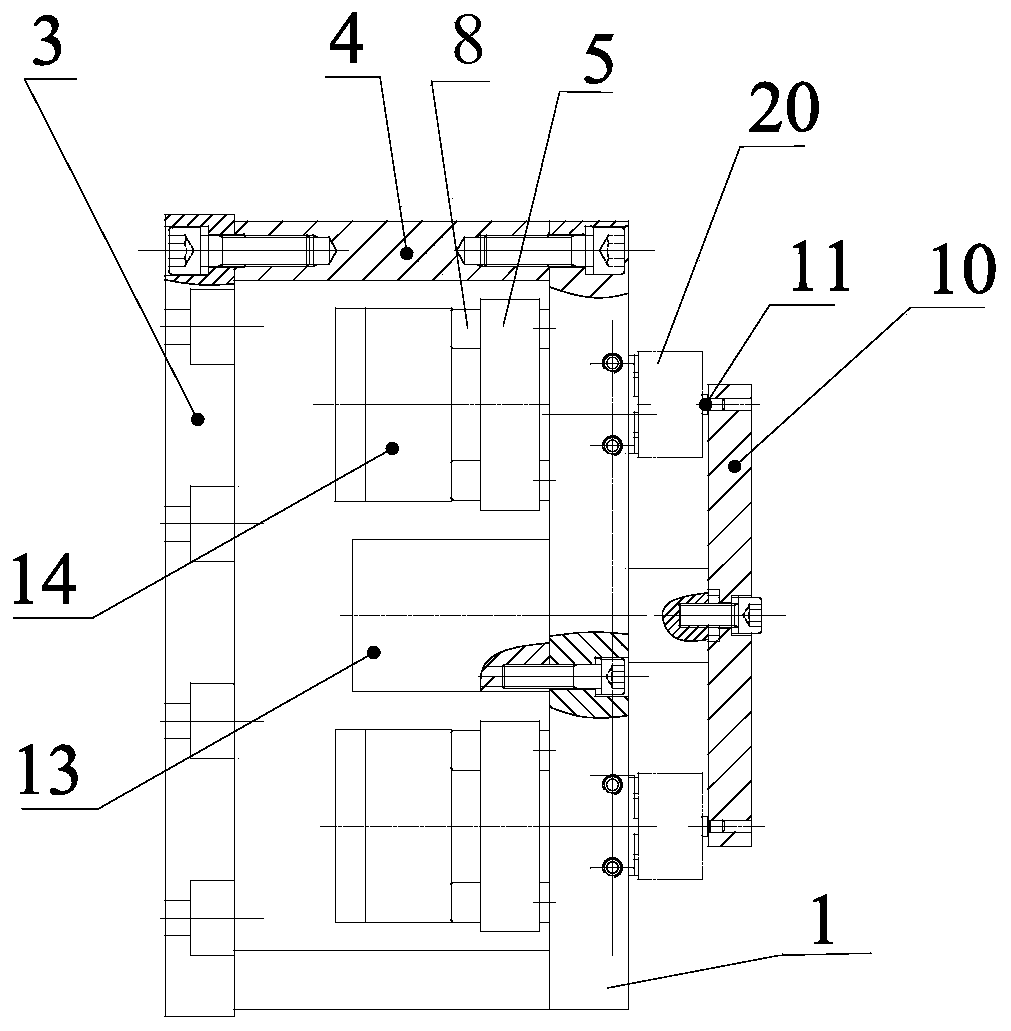

[0040] Figure 1-Figure 16 Some embodiments according to the invention are shown.

[0041] Such as Figure 1-Figure 3 As shown, a combined pneumatic machining fixture suitable for multiple varieties of shaft sleeves includes an upper panel and a supporting structure. The upper panel includes a first upper panel 1 and a second upper panel 2. The supporting structure includes a bottom plate 3 and two side panels 4 , wherein two side plates 4 stand on both sides of the bottom plate 3 respectively, and are fixed to the bottom plate 3 by bolts; the first upper panel 1 and the second upper panel 2 are placed on the side plates 4 respectively, and several through holes are processed on them 110, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com