Ti (C, N)-based metal ceramic with positive gradient ring core phase and preparation method thereof

A technology of base metal and ring core, applied in the field of Ti-based cermet and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

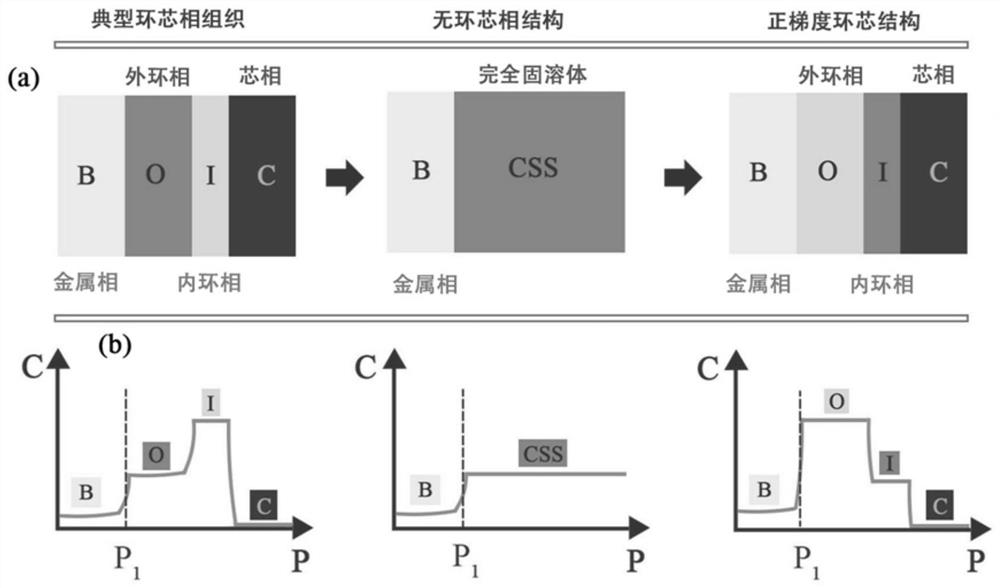

AI Technical Summary

Problems solved by technology

Method used

Image

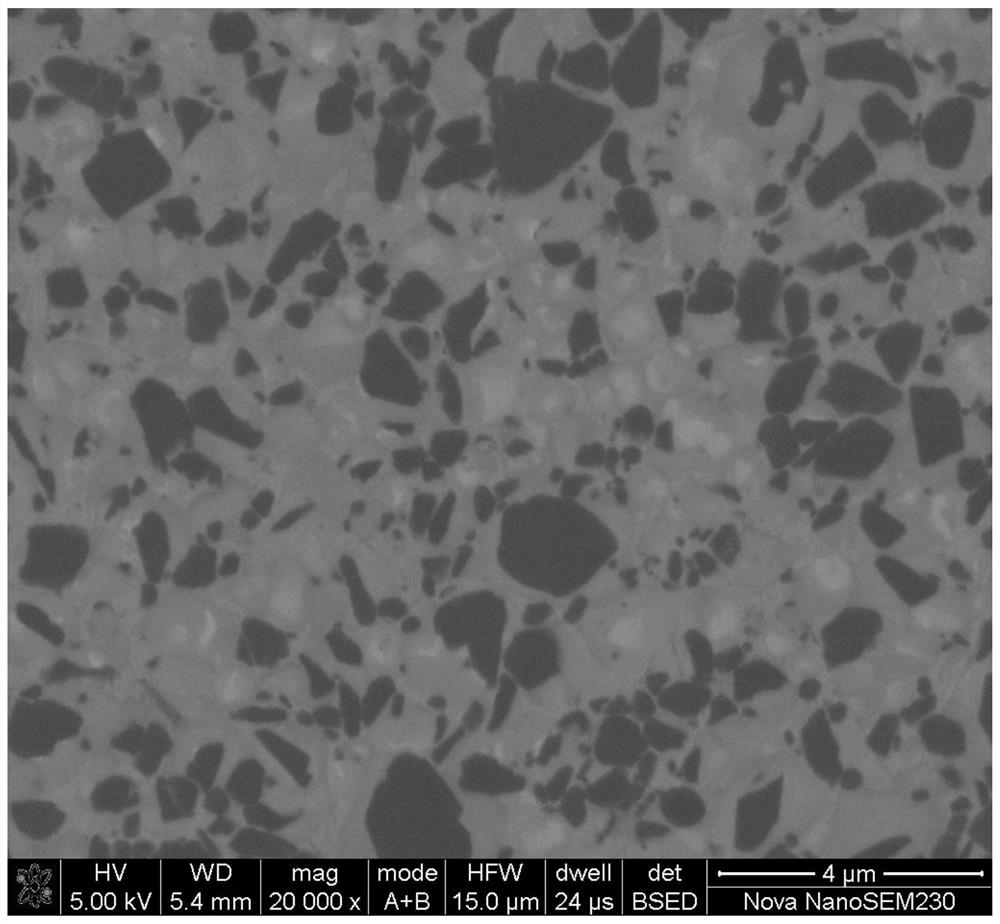

Examples

Embodiment 1

[0053] Composition: 45Ti(C,N)-25WC-11.1Mo 2 C-3TaC-15(60Ni35Co-5Ti)-0.9C cermet

[0054] The mass fraction of the cermet composition is 45 parts of Ti(C, N), 25 parts of WC, 11.1 parts of Mo 2 C, 3.0 parts of TaC and 15.0 parts of binder phase. The average particle sizes of Ti(C,N), WC and Mo2C are 1.5 μm, 15 μm and 8 μm, respectively; the composition of the binder phase is 60 parts of nickel, 35 parts of cobalt and 5 parts of titanium.

[0055] The preparation steps of the cermet are as follows: (1) Put the weighed Ti(C,N) powder, TaC powder, metal binder phase powder and carbon black in a ball mill jar, add absolute ethanol until the ball and the surface of the powder; the ball mill barrel is subjected to roller milling, the ball-to-material ratio is 12:1, the rotating speed is 80r / min, and the ball milling time is 40h; (2) After the first ball milling, add the corresponding WC and Mo to the mixture 2 C powder, and 2% molten paraffin, and then ball milled for 4 hours, the...

Embodiment 2

[0058] Composition: 50Ti(C,N)-20WC-8Mo 2 C-1.7NbC-18(50Ni42Co-7Ni3Ti)-2.3C cermet, the mass fraction of the cermet components is 50 parts of Ti(C,N), 20 parts of WC, 8 parts of Mo 2 C, 1.7 parts of NbC, 18 parts of titanium-containing binder phase, 2.3 parts of C. Among them Ti(C,N), WC and Mo 2 The average particle sizes of C are 2.1 μm, 18 μm and 12 μm, respectively.

[0059] The preparation steps of the cermet are: (1) put the weighed Ti(C,N) powder, NbC powder, metal binder phase powder and carbon black in a ball mill jar, add absolute ethanol until the ball and the surface of the powder; the ball mill barrel is subjected to roller milling, the ball-to-material ratio is 10:1, the rotating speed is 100r / min, and the ball milling time is 40h; (2) After the first ball milling, add the corresponding WC and Mo to the mixture 2 C powder, and 3% molten paraffin, and then carry out ball milling 15h, and ball milling rate is 50r / min; (3) carry out vacuum drying to powder subsequ...

Embodiment 3

[0062] Composition: 52Ti(C,N)-15WC-6Mo 2 C-1.5TaC-22(50Ni40Co-10Ti)-3.5C cermet

[0063] The mass fraction of the cermet composition is 52 parts of Ti(C, N), 15 parts of WC, 6 parts of Mo 2 C, 1.5 parts of NbC, 22 parts of titanium-containing binder phase, 3.5 parts of C. Among them Ti(C,N), WC and Mo 2 The average particle sizes of C are 2.1 μm, 18 μm and 12 μm, respectively.

[0064] The preparation steps of the cermet are: (1) put the weighed Ti(C,N) powder, NbC powder, metal binder phase powder and carbon black in a ball mill jar, add absolute ethanol until the ball and the surface of the powder; the ball mill barrel is subjected to roller milling, the ball-to-material ratio is 10:1, the rotating speed is 100r / min, and the ball milling time is 30h; (2) After the first ball milling, add the corresponding WC and Mo to the mixture 2 C powder, and 3% molten paraffin, and then carry out ball milling 20h, and ball milling speed is 40r / min; (3) carry out vacuum drying to powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com