Dressing control system and method for grinding wheel

A technology of control system and grinding wheel, which is applied in the direction of automatic grinding control devices, manufacturing tools, grinding machine parts, etc., can solve the problems of less substrate removal, low processing efficiency, rough substrate surface processing, etc., and achieve improved The effect of processing efficiency and surface processing accuracy, ensuring grinding ability, and increasing removal amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

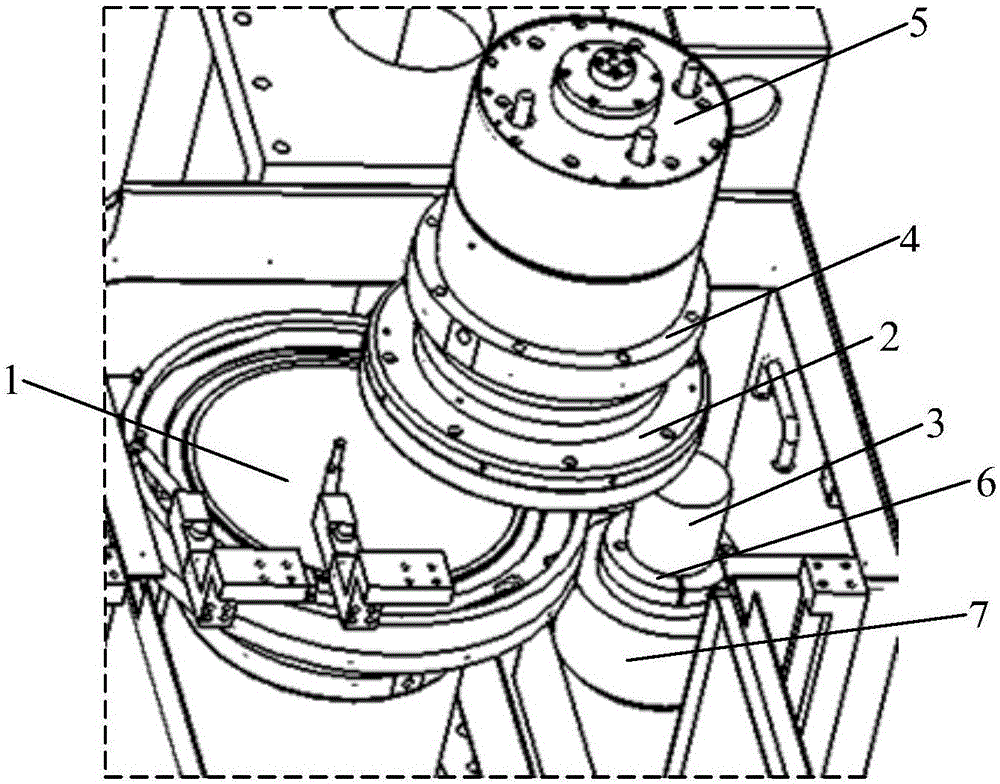

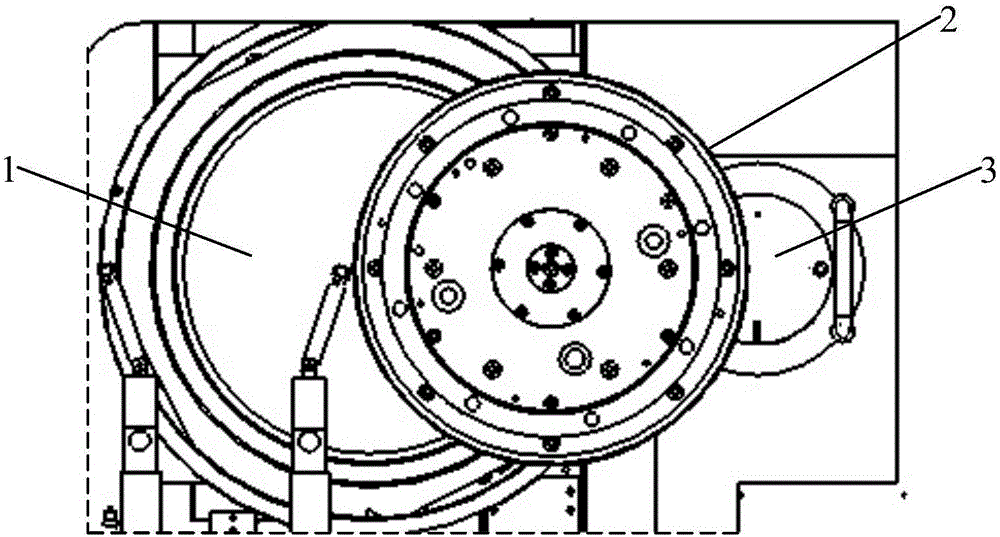

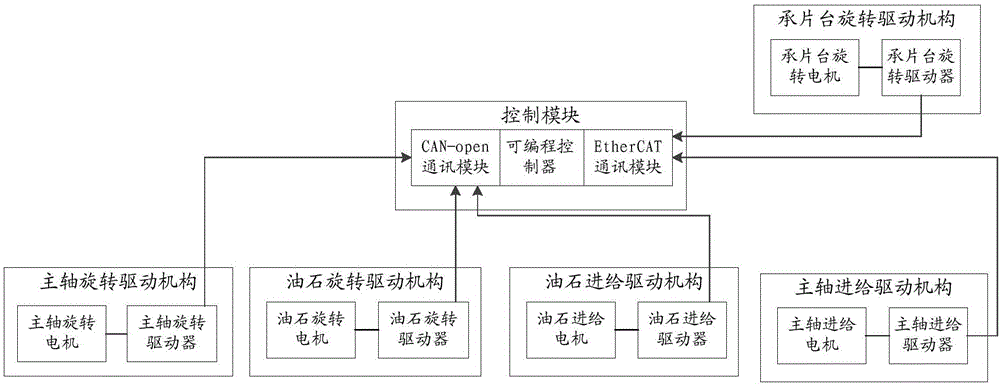

[0051] Such as figure 1 As shown, the embodiment of the present invention provides a dressing control system for a grinding wheel, including:

[0052] Carrier mechanism, spindle grinding mechanism, oilstone dressing mechanism;

[0053] What needs to be explained here is that the chip holder mechanism includes: the chip holder 1; the main shaft grinding mechanism includes: the main shaft (not shown in the figure) and the main shaft grinding wheel 2 connected with the main shaft; the oil stone dressing mechanism includes: the oil stone 3 and the brush ( not shown in the figure).

[0054] A spindle rotation drive mechanism 4 for driving the rotation of the spindle grinding mechanism;

[0055] A spindle feed drive mechanism 5 for driving the spindle grinding mechanism to move axially along the spindle of the spindle grinding mechanism;

[0056] A wafer table rotation drive mechanism (not shown in the figure) for driving the wafer table mechanism to rotate;

[0057] The whetsto...

no. 2 example

[0107] Such as Figure 4 As shown, the embodiment of the present invention also provides a grinding wheel dressing control method, which is applied to the grinding wheel dressing control system in the first embodiment, including:

[0108] Step 101, according to the pre-recorded first distance value of the whetstone in the whetstone trimming mechanism from the preset whetstone zero point position to the wafer stage in the wafer stage mechanism, control the whetstone rotation drive mechanism to drive the The whetstone rotates at a first preset speed, and controls the whetstone feeding drive mechanism to drive the whetstone to move upwards at a first preset speed in a direction parallel to the axial direction of the main shaft relative to the preset whetstone zero position When the second predetermined position is reached, the upward movement is stopped, and the second predetermined position is the first distance value + the initial thickness of the substrate material to be groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com