A kind of mechanical material preparation mold

A mold and mechanical technology, which is applied in the field of mechanical materials to prepare molds, can solve the problems of poor dimensional stability of metal antennas, affecting surface processing accuracy, and difficult control of surface accuracy, etc., to achieve low processing economic cost, short processing cycle, and high surface quality. The effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

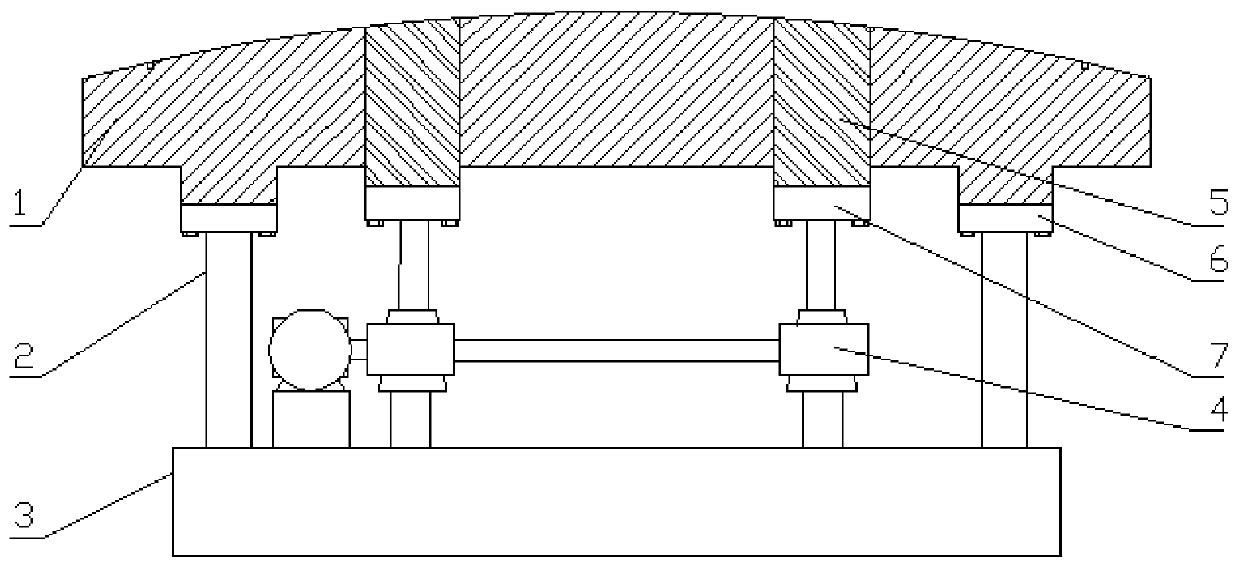

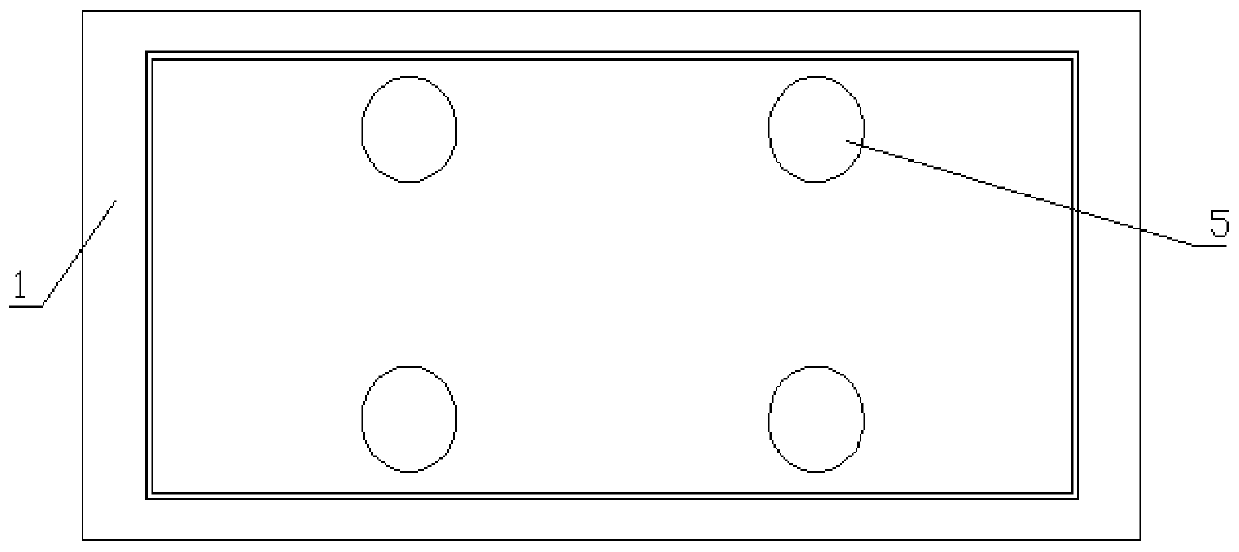

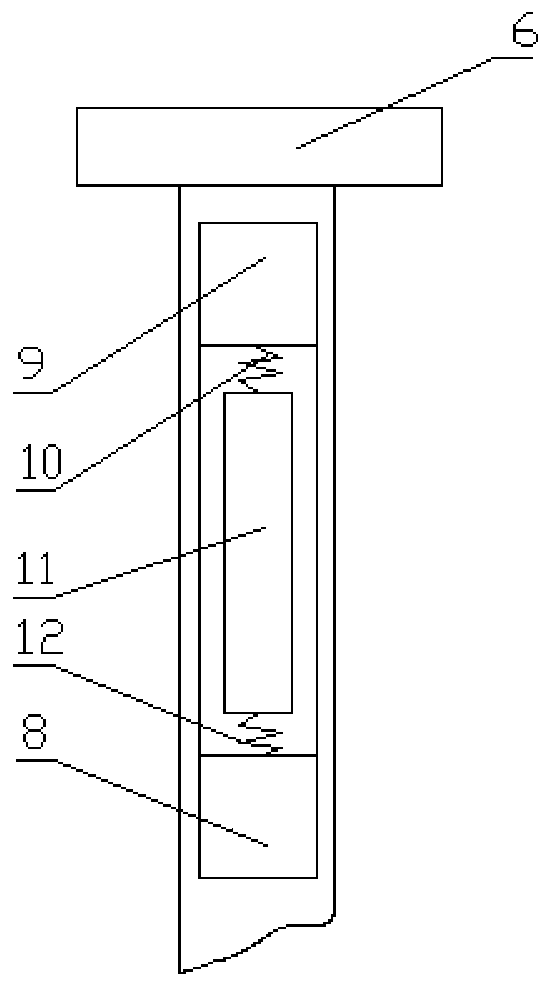

[0023] The present invention provides a kind of mechanical material preparation mold, combines below Figure 1 to Figure 3 The structure schematic diagram of the present invention is described.

[0024] Such as Figure 1 to Figure 3 As shown, a mold for preparing mechanical materials provided by the present invention includes a base body 3, the four corners of the upper surface of the base body 3 are respectively provided with support columns 2, and the interior of the support column 2 is provided with a shock absorbing device. The upper end of the column 2 is provided with a first connection plate 6, and the upper surface of the first connection plate 6 is provided with a female mold 1, and the female mold 1 is provided with a plurality of evenly distributed mounting holes one, and the mounting holes one A filling body 5 matching the mounting hole is disposed inside, a second connecting plate 7 is disposed at the lower end of the filling body 5 , and a lifting device 4 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com