Bakelite idler and its making process

A manufacturing method and technology of electro-adhesive, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve the problems of easy evaporation and flow of lubricants, inconvenient transportation and installation, and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

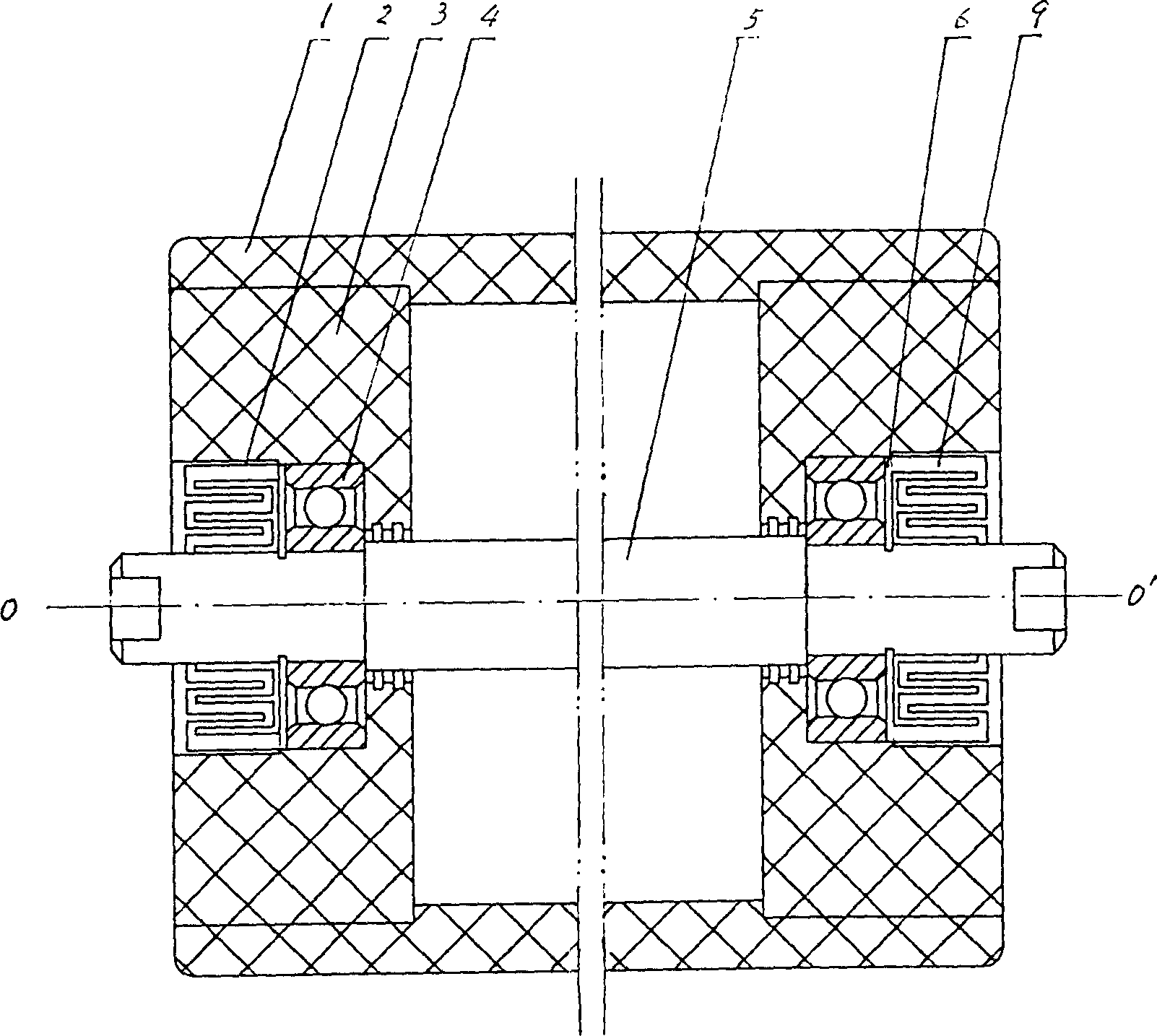

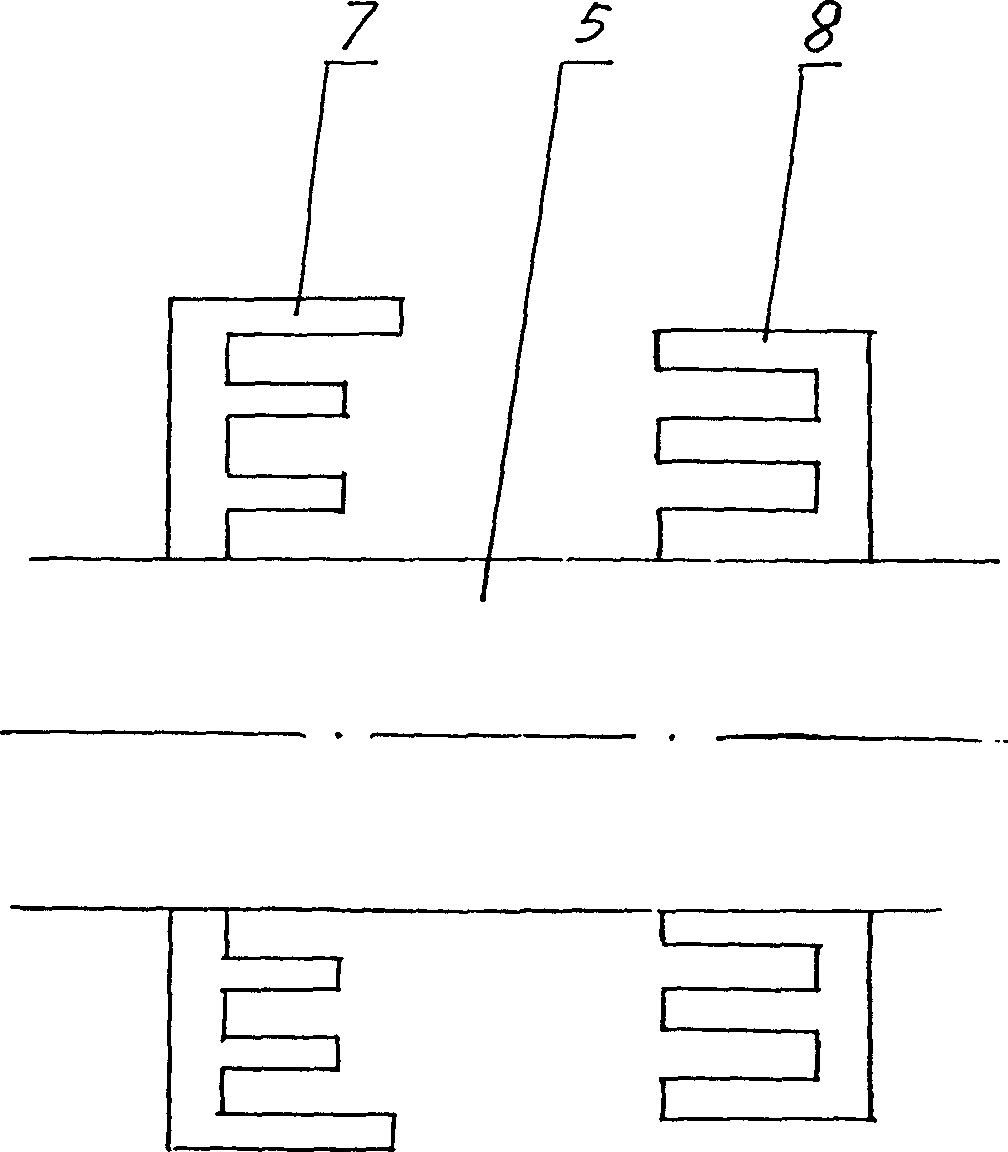

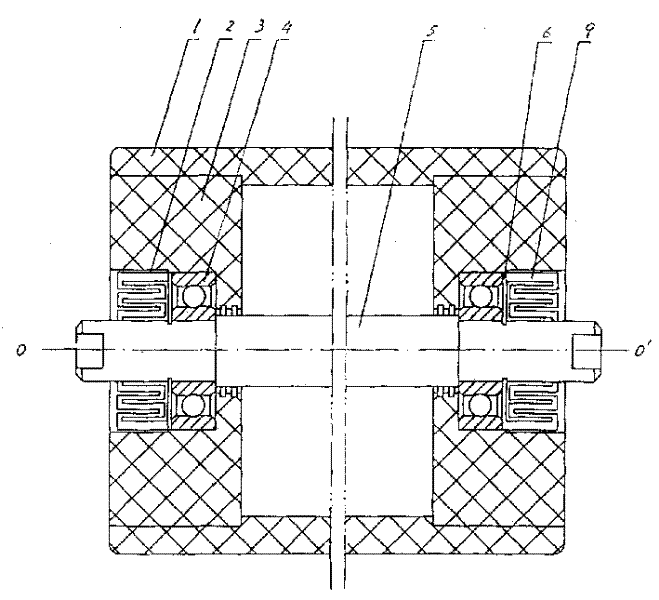

[0009] An electric bakelite idler. The outer tube 1 and the bearing seats 3 installed at both ends of the bakelite roller are all bakelite material products composed of glass fiber cloth and glue made of epoxy resin and phenolic resin. The rotating shaft 5 is inserted on the central axis 00' of the bearing seats 3 at both ends. The inner ball bearing 4 and the outer labyrinth combined seal 2 are fitted between the bearing seat 3 and the rotating shaft 5. The combined seal is composed of two seal ring components. The longitudinal half cross-sectional shape of one sealing ring assembly 7 is shaped, and the longitudinal half cross-sectional shape of the other sealing ring assembly 8 is shaped. They are interspersed with each other in the tortuous enclosed space formed in the middle to contain lubricating oil 9. Between the bearing 4 and the outer labyrinth combined seal 2 there is a circlip 6 which isolates them and is sleeved on the rotating shaft 5.

[0010] The manufacturing metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com