Vacuum insulation plate sealing machine and sealing process for sealing vacuum insulation plate by utilizing same

A technology of vacuum insulation panels and sealing machines, which is applied to mechanical equipment, heat exchange equipment, and pipelines through thermal insulation protection, etc., can solve the problems of difficulty in guaranteeing the quality and service life of vacuum insulation panels, and achieve tight coordination, simple operation, and structure. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

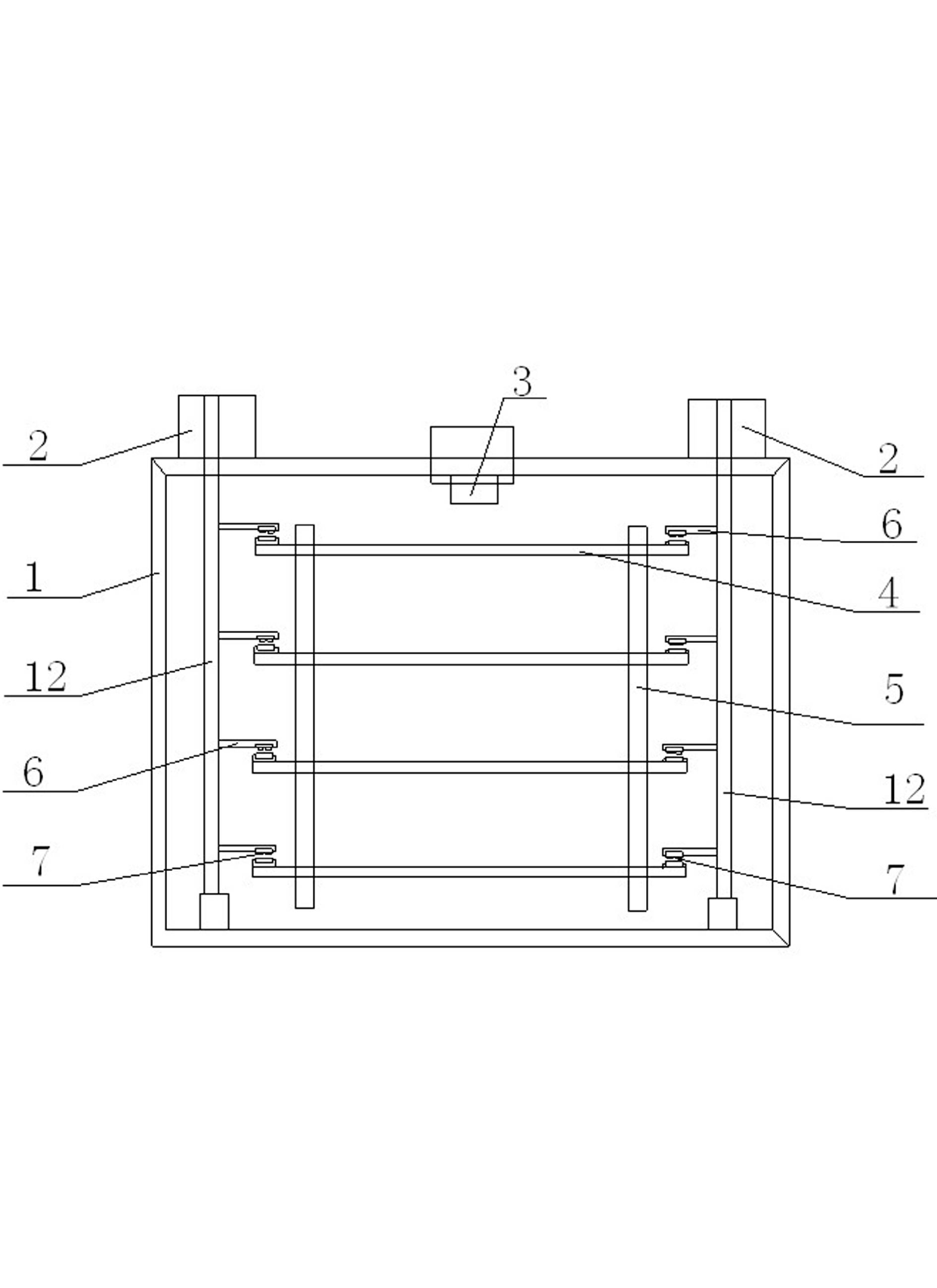

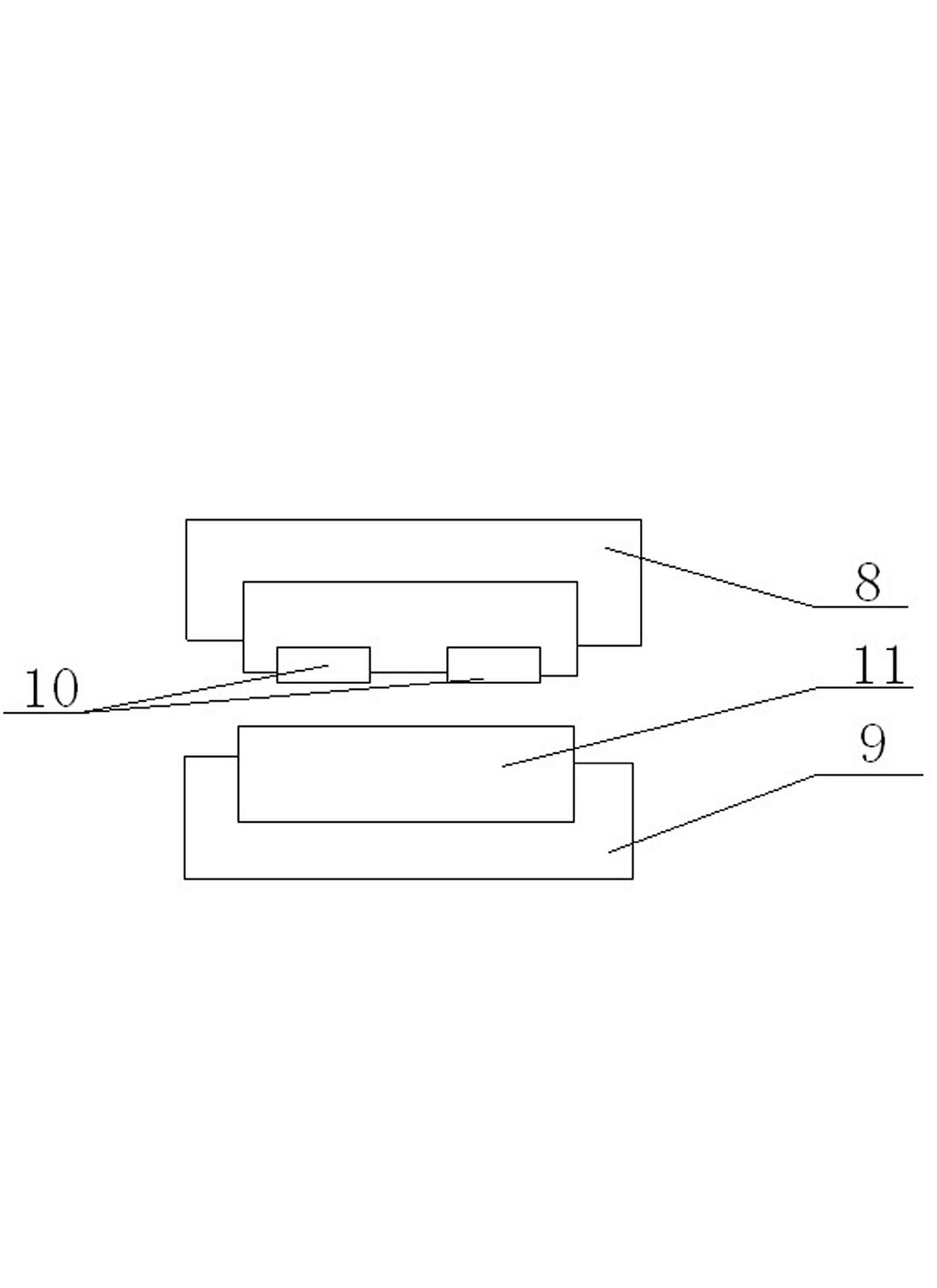

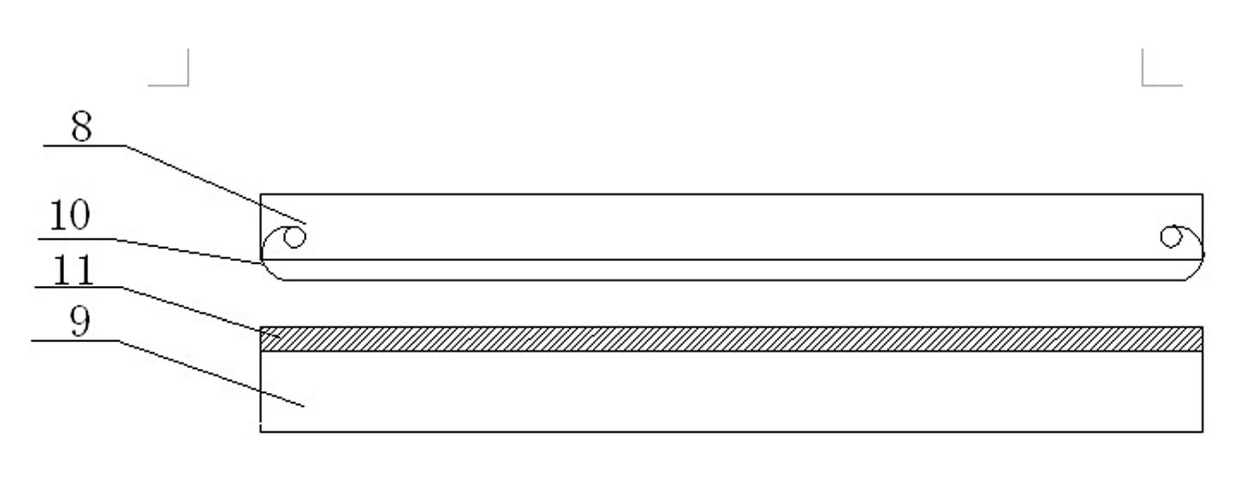

[0016] Such as figure 1 As shown in -3, the vacuum insulation panel sealing machine of the present invention includes a box body 1, a cylinder 2 arranged on both sides of the outer top of the box body 1, a vacuum pump 3 arranged above the box body 1, and a cylinder set in the box body 1. A plurality of storage racks 4 and a frame 5 supporting the storage racks 4, the cylinder shaft 12 stretches into the inside of the casing 1, and the cylinder shaft 12 is provided with a plurality of cylinder connecting rods 6, and the two ends of each storage rack 4 All are provided with sealing device 7, and each sealing device 7 comprises the upper bakelite 8 that is fixedly connected with cylinder connecting rod 6, the lower layer bakelite 9 that is fixed on the rack 4 and the silicone strip 11 that is attached on the lower layer bakelite 9, the upper layer bakelite 8 Two heating sealing strips 10 are arranged below the bottom of the bottom, the part of the silicone strip 11 protrudes abov...

Embodiment 2

[0019] Such as figure 1 As shown in -3, the vacuum insulation panel sealing machine of the present invention includes a box body 1, a cylinder 2 arranged on both sides of the outer top of the box body 1, a vacuum pump 3 arranged above the box body 1, and a cylinder set in the box body 1. A plurality of storage racks 4 and a frame 5 supporting the storage racks 4, the cylinder shaft 12 stretches into the inside of the casing 1, and the cylinder shaft 12 is provided with a plurality of cylinder connecting rods 6, and the two ends of each storage rack 4 All are provided with sealing device 7, and each sealing device 7 comprises the upper bakelite 8 that is fixedly connected with cylinder connecting rod 6, the lower layer bakelite 9 that is fixed on the rack 4 and the silicone strip 11 that is attached on the lower layer bakelite 9, the upper layer bakelite 8 Two heating sealing strips 10 are arranged below the bottom of the bottom, the part of the silicone strip 11 protrudes abov...

Embodiment 3

[0022] Such as figure 1 As shown in -3, the vacuum insulation panel sealing machine of the present invention includes a box body 1, a cylinder 2 arranged on both sides of the outer top of the box body 1, a vacuum pump 3 arranged above the box body 1, and a cylinder set in the box body 1. A plurality of storage racks 4 and a frame 5 supporting the storage racks 4, the cylinder shaft 12 stretches into the inside of the casing 1, and the cylinder shaft 12 is provided with a plurality of cylinder connecting rods 6, and the two ends of each storage rack 4 All are provided with sealing device 7, and each sealing device 7 comprises the upper layer bakelite 8 that is fixedly connected with cylinder connecting rod 6, the lower layer bakelite 9 that is fixed on the rack 4 and the silica gel strip 11 that is attached on the lower layer bakelite 9, the upper layer The bottom of the bakelite 8 is provided with two heating sealing strips 10, the part of the silica gel strip 11 protrudes abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com