Graphite commutator

A commutator and graphite technology, applied in the direction of current collectors, rotary current collectors, electrical components, etc., can solve the problems of small effective grasping force, low connection strength, detachment and other problems, and achieve strong effective grasping force, long service life, Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

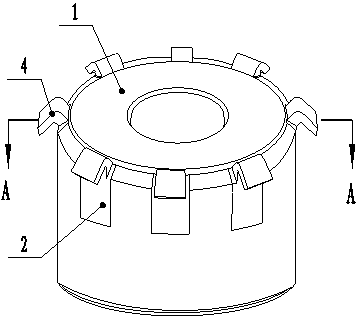

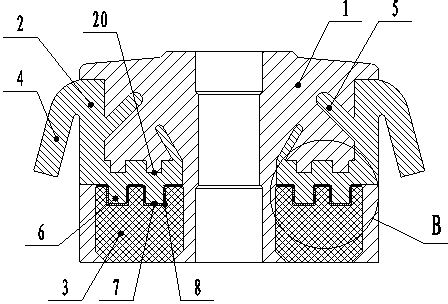

[0035] Embodiment one: combined with attached figure 1 , 2 , a graphite commutator, including bakelite 1, commutator piece 2 and graphite piece 3, bakelite 1, commutator piece 2 and graphite piece 3 are integrally injection molded, and commutator piece 2 is an "L" type structure, The inner side of the reversing piece 2 is respectively provided with a tab 5, the upper end is provided with a hook foot 4 with an outer flanging, and the lower end is provided with a pin 6, the graphite sheet 3 is completely surrounded by the bakelite 1, and is fixed with the reversing piece 2. , The graphite sheet 3 is provided with a densely formed first groove 7, the first groove 7 is consistent with the shape of the pin 6, and the tin welding fits or fits without gaps.

[0036] During production, the graphite sheet and the commutator sheet are first made into shapes, and the first groove on the graphite sheet is densified, and then the pins of the commutator sheet are pressed into the first gr...

Embodiment 2

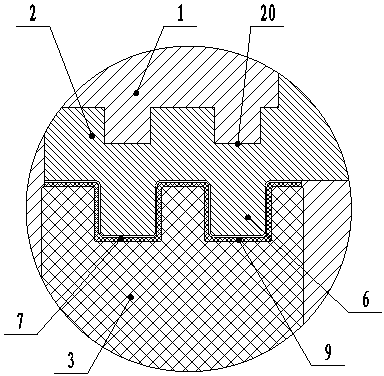

[0037] Embodiment two: combined with attached figure 1 , 2 , 3, 4, 5, a graphite commutator, comprising bakelite 1, commutator piece 2 and graphite piece 3, bakelite 1, commutator piece 2 and graphite piece 3 integral injection molding, commutator piece 2 is The "L" shape structure made of copper alloy, the inner side of the commutator piece is respectively provided with a tongue 5, the upper end is provided with a hook foot 4 with a flanging edge, the lower end is provided with a pin 6, and the upper surface of the lower end is provided with a second concave. Slot 20, graphite sheet 3 is completely surrounded by Bakelite 1, graphite sheet 3 is provided with two densely formed triangular grooves 10, pin 6 is a triangular columnar body 11 consistent with the shape of triangular groove 10, triangular groove 10 and The triangular columnar body 11 is tin-welded or gap-free, and the upper surface of the graphite sheet 3 and the triangular groove 10 are provided with a conductive ...

Embodiment 3

[0039] Embodiment three: combined with attached figure 1 , 2 , 6, 7, a graphite commutator, comprising bakelite 1, commutator piece 2 and graphite piece 3, bakelite 1, commutator piece 2 and graphite piece 3 integral injection molding, commutator piece 2 is copper metal The "L" type structure is made, the inner side of the commutator piece 2 is respectively provided with a tongue 5, the upper end is provided with a hook foot 4 with a flanging edge, the lower end is provided with a pin 6, and the upper surface of the lower end is provided with a second groove. 20. The graphite sheet 3 is completely surrounded by Bakelite 1. The graphite sheet 3 is provided with two densely formed square grooves 12. The pin 6 is a square columnar body 13 that is consistent with the shape of the square groove 12, and the square groove 12 and The square columnar body 13 is tin-welded or gap-free, and the upper surface of the graphite sheet 3 and the square groove 12 are provided with a copper fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com