Segmented liquid level sensor based on capacitance-to-digital conversion technology

A capacitive sensor and liquid level sensor technology, applied in the field of sensors, can solve the problems of lack of mature experience and technology, lack of automatic balancing measures, unsuitable for online measurement, etc., achieve the effect of less maintenance, avoid switching, and reduce requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

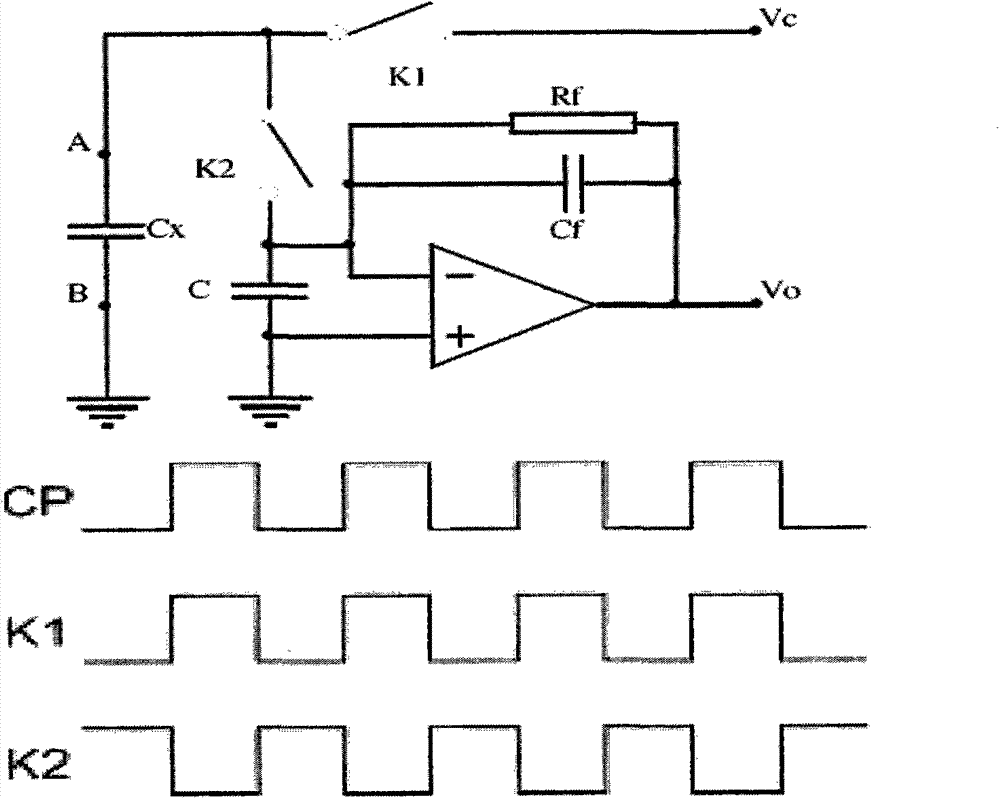

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

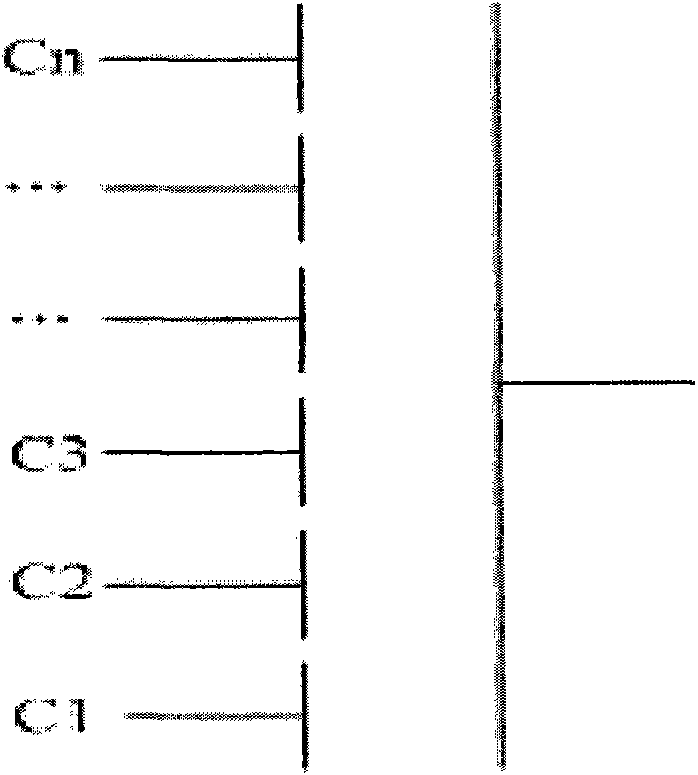

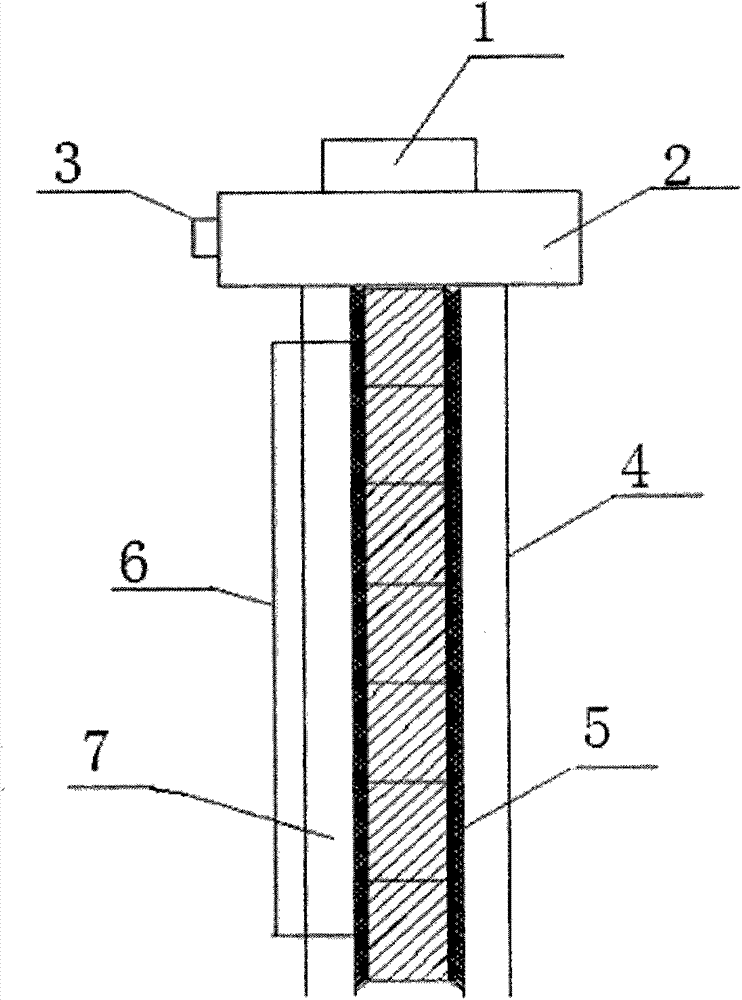

[0031] refer to Figure 3-6 , this specific embodiment adopts the following technical solutions: a segmented liquid level sensor based on capacitive digital conversion technology, including sensor upper cover 1, waterproof sensor junction box 2, aviation plug 3, capacitive sensor outer pole cylinder 4, polytetrafluoroethylene Vinyl insulating layer 5, seven-segment sensor inner pole cylinder 6, seven-segment sensor inner pole cylinder 6 is arranged inside the capacitive sensor outer pole cylinder 4, seven-segment sensor inner pole cylinder 6 is a copper foil electrode pasted on Bakelite, copper The foil electrode is connected to the junction box 2 of the waterproof sensor through a lead wire, and the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com