Assembled house adopting new structural system

A house and housing technology, which is applied in the field of housing construction, can solve the problems of large investment scale, high construction cost, and inability to adapt to concrete prefabricated component processing plants, and achieves convenience for large-scale production, low building cost, and technical requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

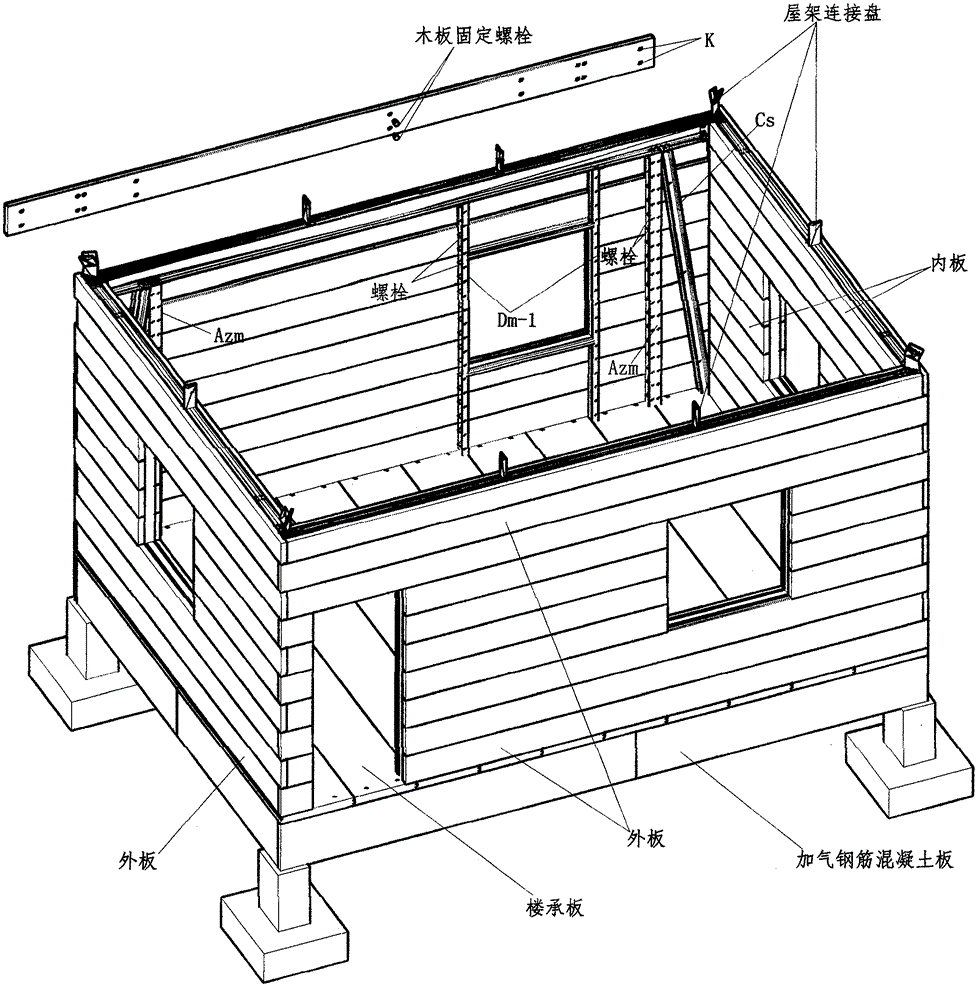

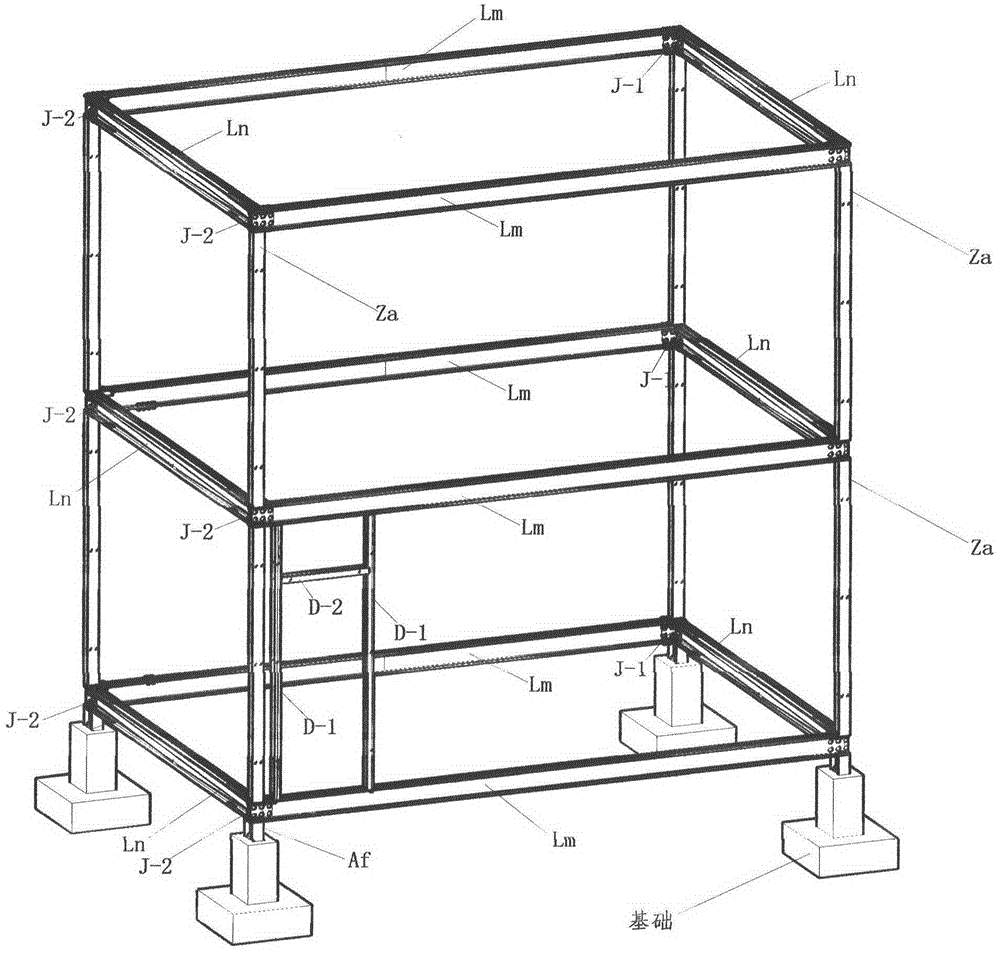

[0045] Below, in conjunction with accompanying drawing, specifically describe how to implement building house according to the present invention:

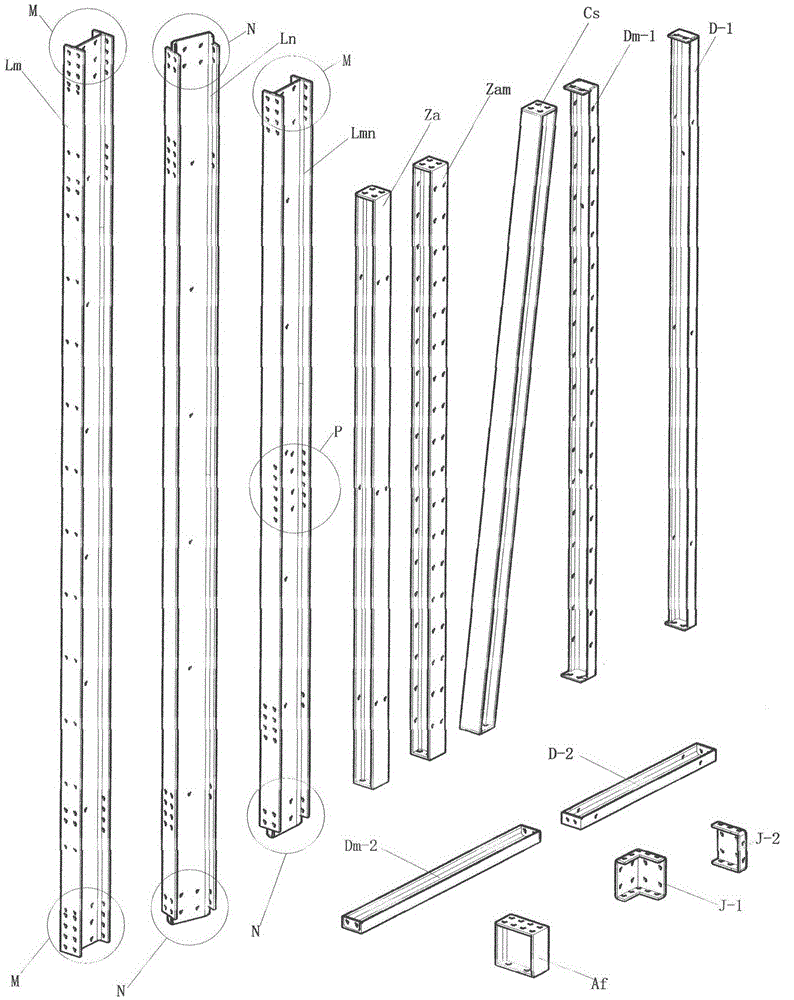

[0046] figure 1 The various components used by the framework A-1, Am-1, A-2 and Am-2 of the present invention are described as follows respectively now:

[0047] 1. Lm, Ln, and Lmn are all components used in the horizontal direction in the frame, collectively referred to as beams, and beams are processed by H-shaped steel or other metal materials with the same cross-section.

[0048]1. There are only two forms of m and n for the shape of the beam end: the shape of m is a group of holes with the same diameter on the web and flange at the end of the beam; the shape of n is except for the web at the end of the beam In addition to a group of holes with the same diameter on the flange and flange, it is also necessary to cut off a section of the upper and lower flanges at the end of the beam.

[0049] 2. For all beams of different leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com