Heavy type automatic edge banding machine controlled by encoder

A technology of encoder and edge banding machine, which is applied in the direction of wood processing equipment, household components, etc., can solve the problems of low degree of automation, achieve a wide range of applications, improve the efficiency of production assembly, and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

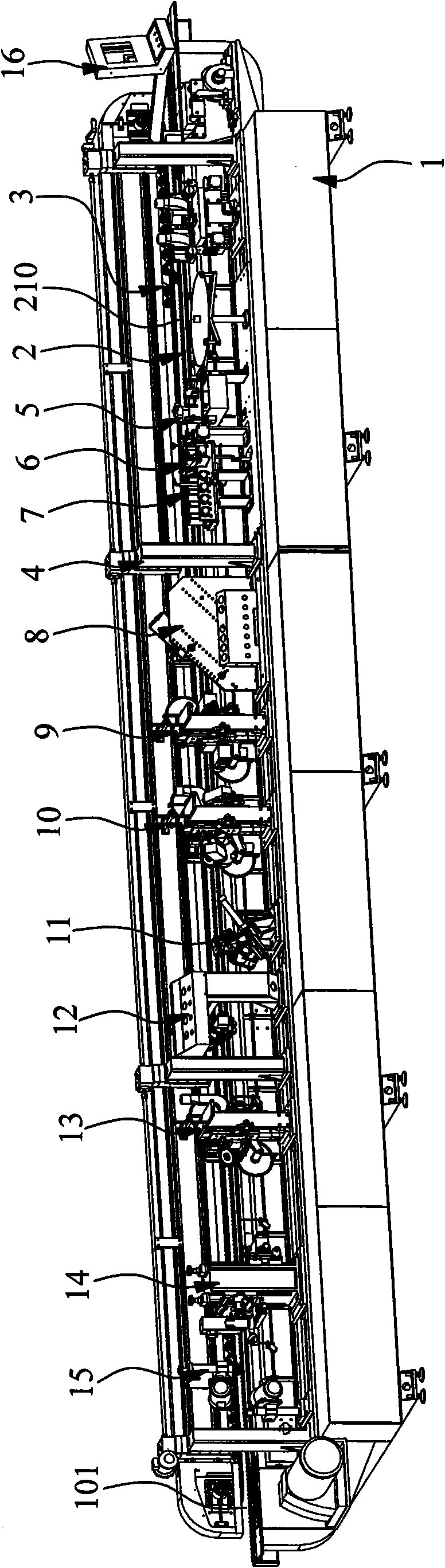

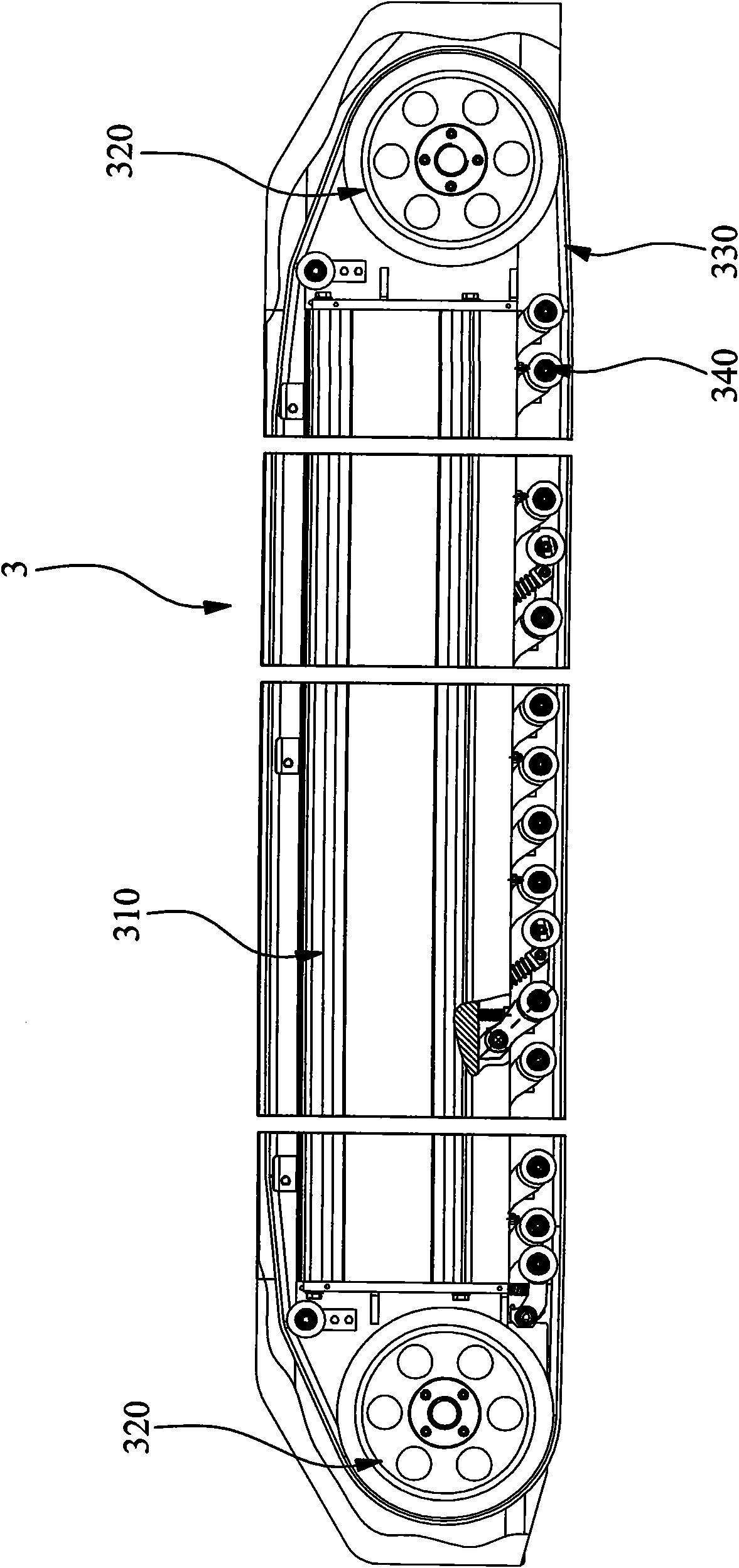

[0040] Please refer to Figure 1 to Figure 20As shown, it shows the specific structure of a preferred embodiment of the present invention, including a frame 1, a chain feeding device 2, a crawler-type pressing device 3, a column assembly 4, a screw pump type glue supply device 5, a cutting Belt device 6, edge band pressing device 7, front and rear rough repair device 8, upper and lower rough repair device 9, upper and lower fine repair device 10, front end fine repair device 11, rear end fine repair device 12, upper and lower edge scraping device 13, opening and closing Groove device 14, upper and lower polishing device 15 and encoder control system 16.

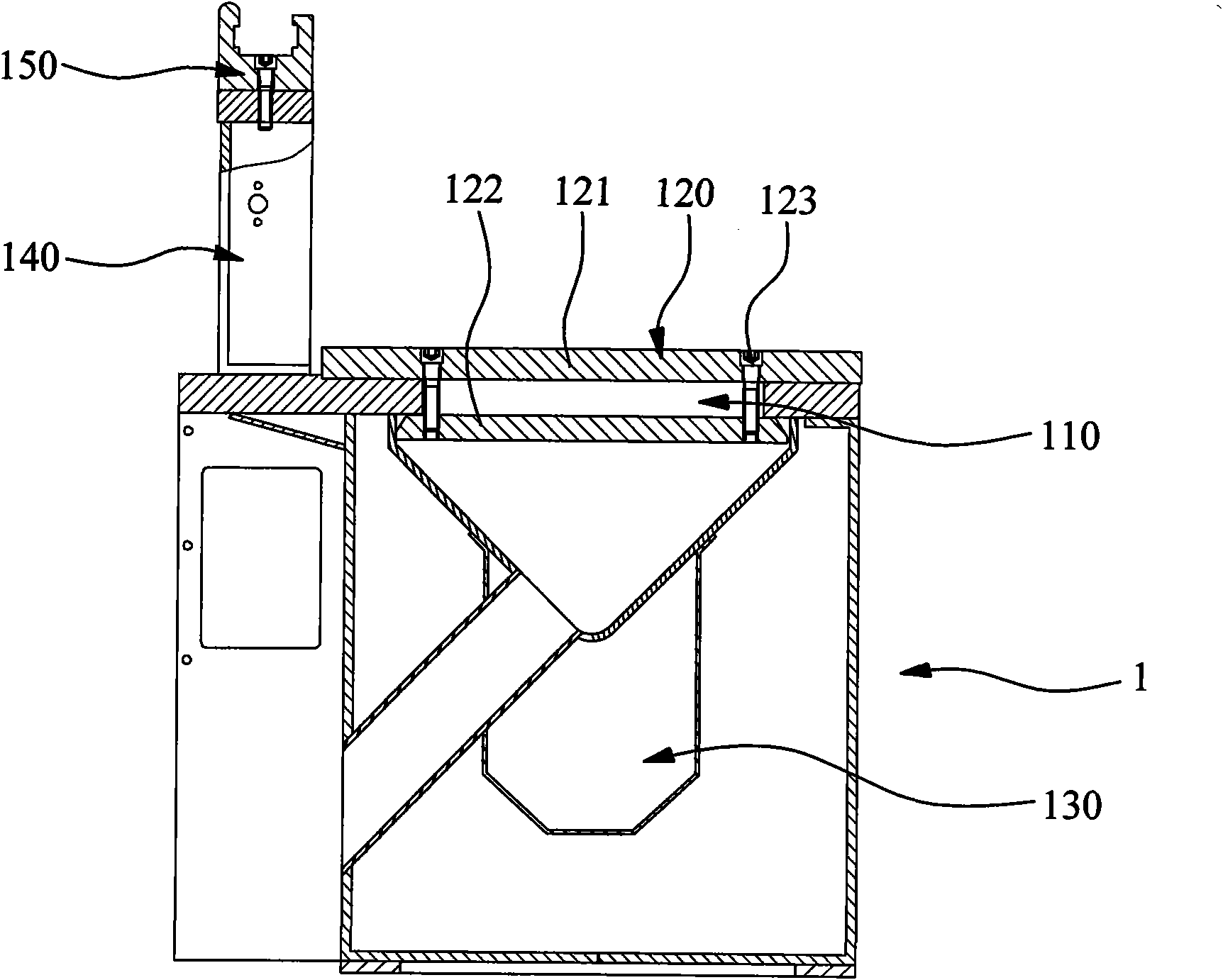

[0041] Among them, such as figure 2 As shown, the frame 1 is a box structure, and a positioning groove 110 is arranged horizontally on the frame 1, and a plurality of mounting seats 120 are movably installed in the positioning groove 110, and each mounting seat 120 includes an upper mounting plate 121 And fixed block 122, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com