Automatic single plate feeding machine

An automatic feeding and veneer technology, applied in conveyors, conveyor objects, rotary conveyors, etc., can solve the problems of increased labor costs and labor intensity, fatigue operation accidents, etc., to reduce labor costs and achieve a high degree of automation. , the effect of reducing the intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

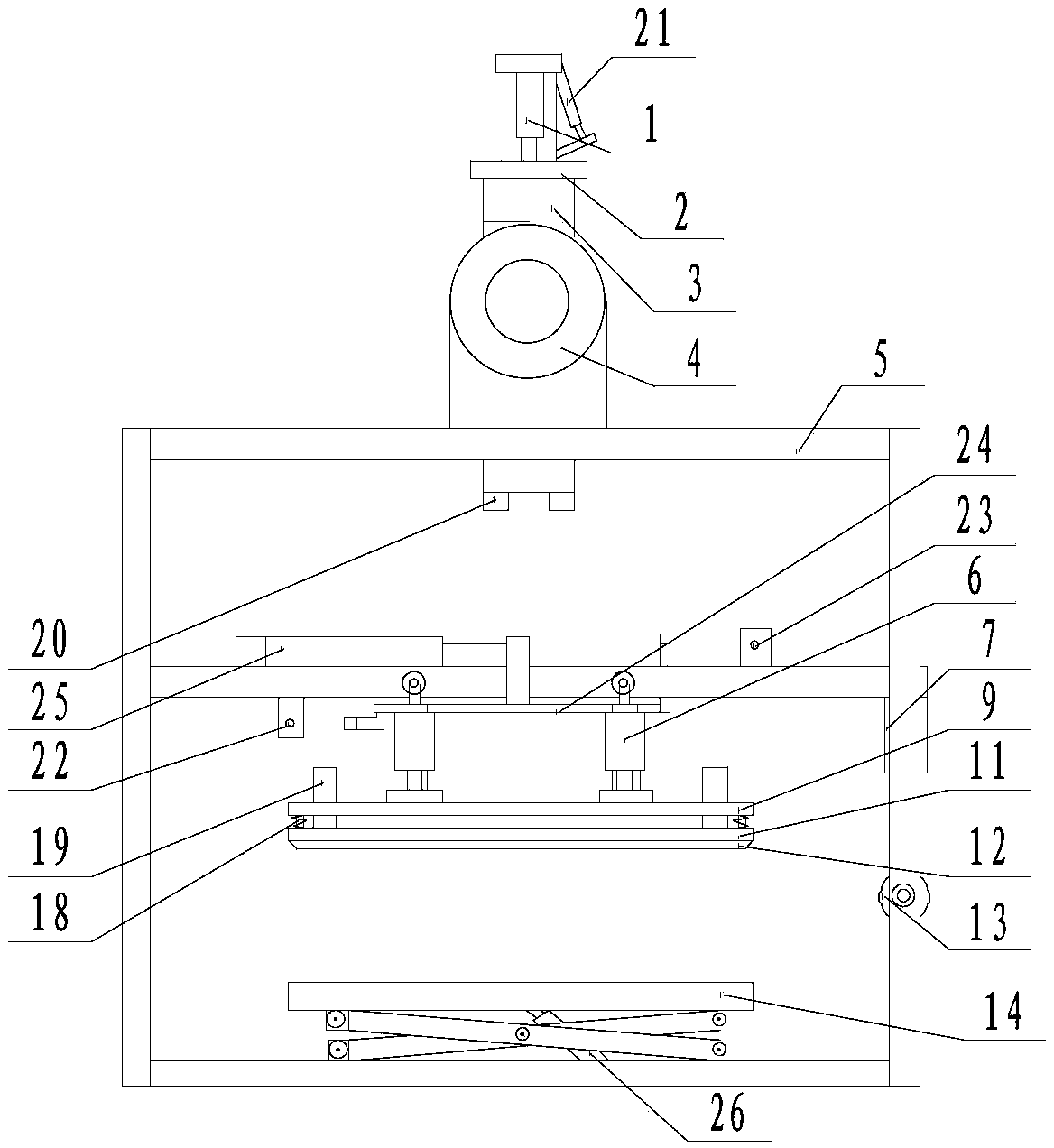

[0044] Embodiment 1: A kind of veneer automatic feeder, comprises frame 5, lifting device, control system, described frame 5 is provided with feeding roller 13, and feeding roller 13 is connected with AC motor, and the frame above feeding roller 13 5 is provided with a power device D 7, and the power device D 7 adopts two double-rod cylinders, and the two double-rod cylinders are provided with rollers 8, and the frame 5 is also provided with a limit sensing device C 15 , limit sensing device D 16, suction feeding device, and air supply system, the limit sensing device C 15 adopts a photoelectric induction sensor, the limit sensing device D 16 adopts a magnetic control proximity switch, and the control system includes a PLC control device 28 , control circuit 29, frequency converter 30, solenoid valve 10.

[0045] The lifting device includes a lifting platform 14 and a jacking cylinder 26, and the jacking cylinder 26 is connected with the lifting platform 14 and a hydraulic pum...

Embodiment 2

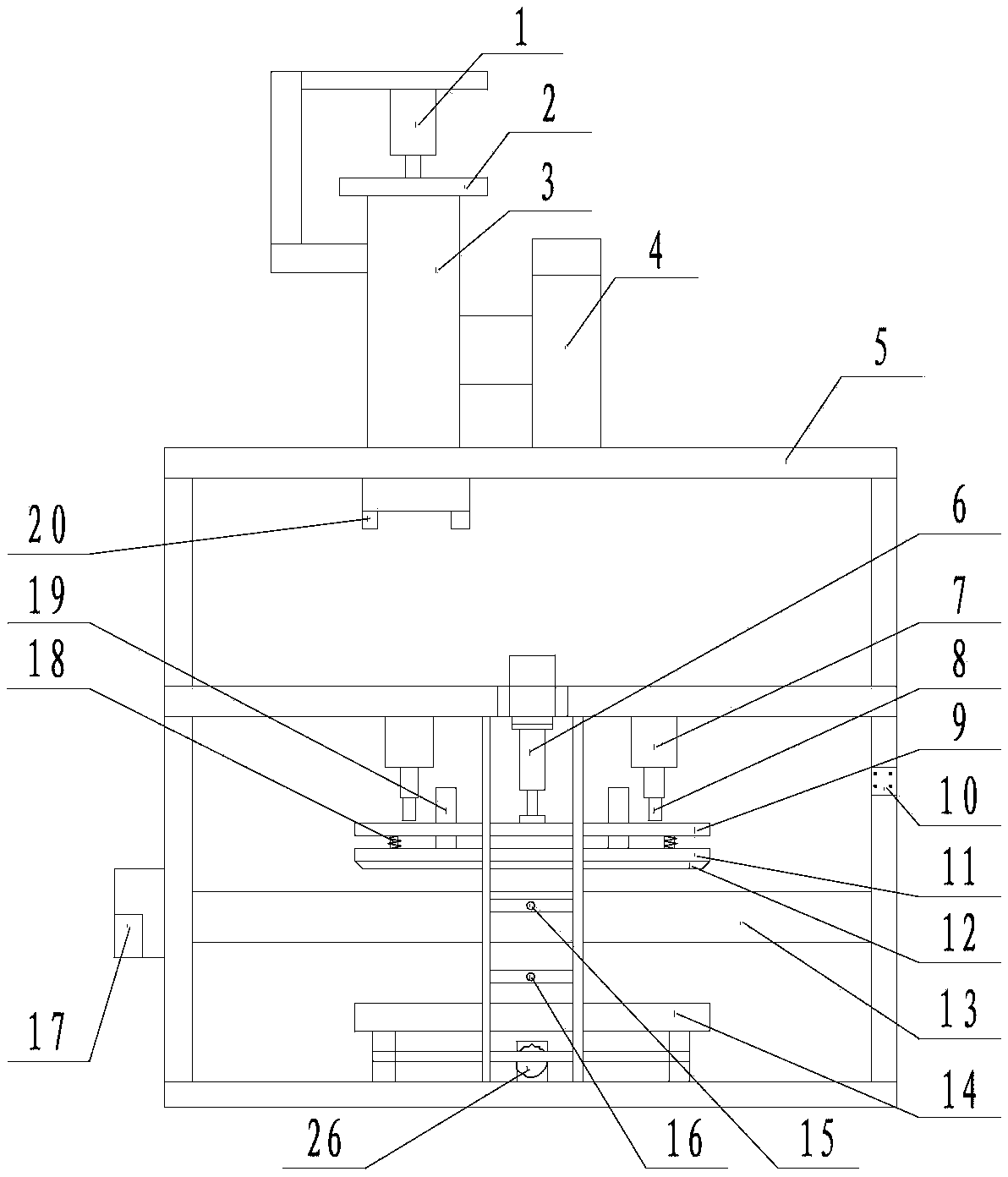

[0050] Embodiment 2: A kind of veneer automatic feeding machine, comprises frame 5, lifting device, control system, described frame 5 is provided with feed roller 13, and feed roller 13 is connected with AC motor, and the frame above feed roller 13 5 is provided with a power device D 7, and the power device D 7 adopts two double-rod cylinders, and the two double-rod cylinders are provided with rollers 8, and the frame 5 is also provided with a limit sensing device C 15 , limit sensing device D 16, suction feeding device, and air supply system, the limit sensing device C 15 adopts a photoelectric induction sensor, the limit sensing device D 16 adopts a magnetic control proximity switch, and the control system includes a PLC control device 28 , control circuit 29, frequency converter 30, solenoid valve 10.

[0051] The lifting device includes a cargo fork 31 , a transmission device 32 , and a hydraulic cylinder 33 , and the hydraulic cylinder 33 is connected to the hydraulic pum...

Embodiment 3

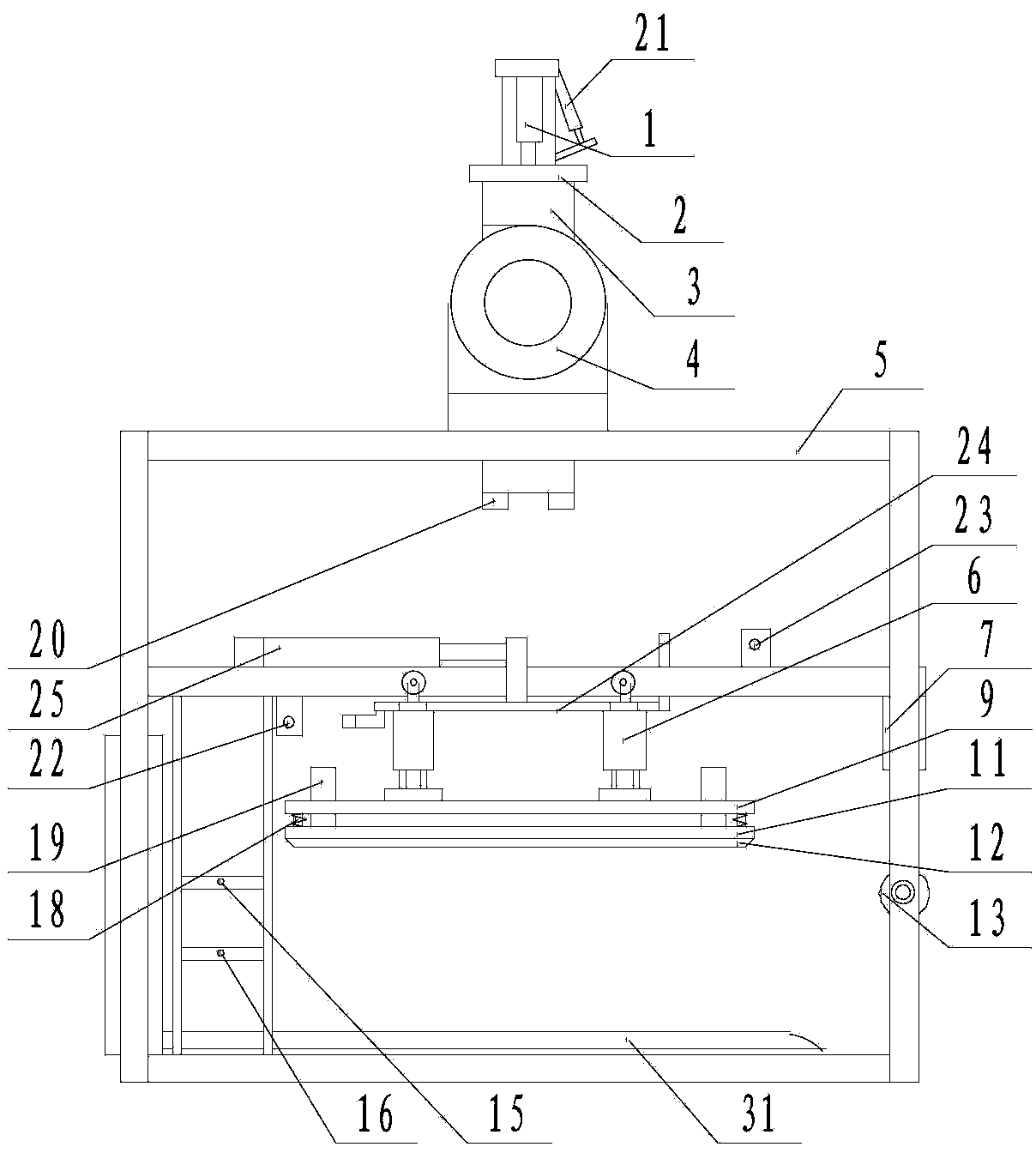

[0056] Embodiment 3: A kind of veneer automatic feeding machine, comprises frame 5, lifting device, control system, described frame 5 is provided with feed roller 13, and feed roller 13 is connected with AC motor, and the frame above feed roller 13 5 is provided with a power device D 7, and the power device D 7 adopts two double-rod cylinders, and the two double-rod cylinders are provided with rollers 8, and the frame 5 is also provided with a limit sensing device C 15 , limit sensing device D 16, two gears and racks are provided and are connected to the suction and feeding device and the air supply system through a synchronous connecting rod, the limit sensing device C 15 adopts a photoelectric sensor, and the limit sensing device D 16 adopts A magnetically controlled proximity switch, the control system includes a PLC control device 28 , a control circuit 29 , a frequency converter 30 , and a solenoid valve 10 .

[0057] Described elevating device comprises lifting oil cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com