Panels made of interlocked wood pieces

a technology of interlocking wood pieces and panels, which is applied in the direction of floor coverings, building components, construction materials, etc., can solve the problem of inability to tilt these pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

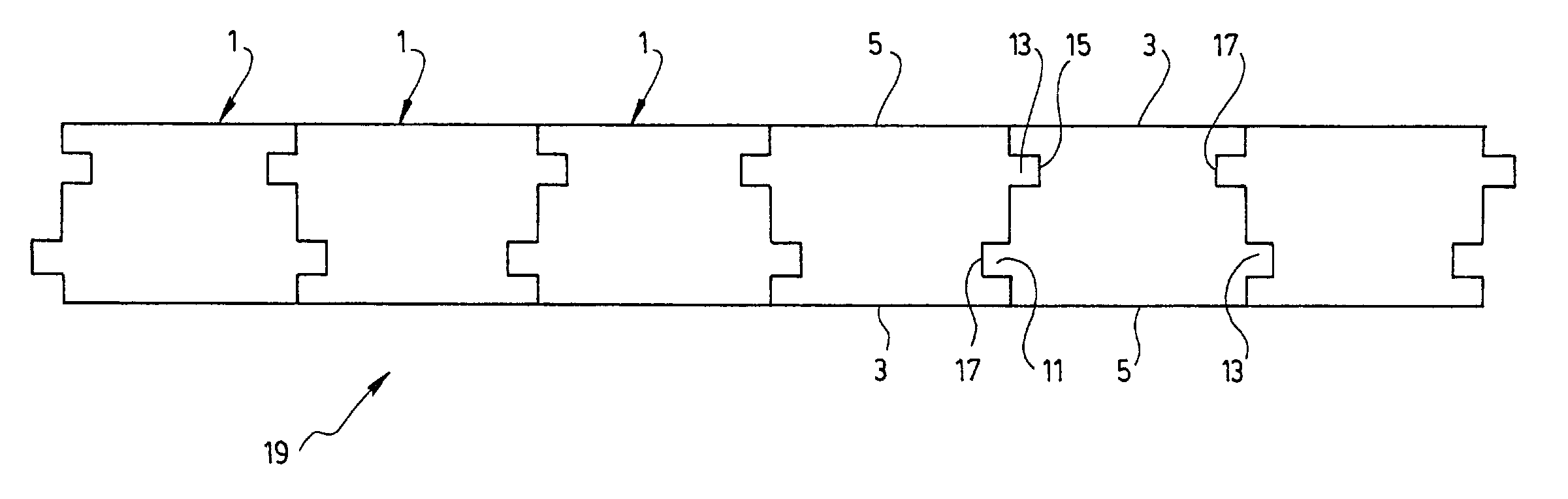

[0051] FIG. 3 shows a wood piece 1 that can be used for the manufacture of a panel according to the invention. This wood piece 1 comprises an upper surface 3, a lower surface 5 and two opposite sidewalls 7,9. The sidewall 7 is provided with a tongue 11 and a groove 15. The opposite sidewall 9 is also provided with the tongue 13 and a groove 17.

[0052] As is shown, the tongues 11 and 13 extend within a same plane P1 that is parallel to the upper surface 3 and lower surface 5 of the wood piece. Similarly, the grooves 15 and 17 extend in a same plane P2 that is parallel to the upper surface 17 and lower surface 5 of the wood piece and thus parallel to the plane P1. The height to which the tongues and grooves are positioned within the planes P1 and P2 on the sidewalls 7 and 9 of the wood piece are selected so that wood pieces 1 of similar shape may be interlocked into each other to form a desired panel, by positioning alternatively one wood piece upside down and another adjacent wood pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com