Preparation method of light transmission bamboo sheet

A technology for bamboo chips and bamboo materials, which is applied in the field of preparation of light-transmitting bamboo chips, can solve the problems of complex process, no fluorescent properties, opacity, etc., and achieves the effects of simple preparation process, accelerated processing speed, and good waterproofing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

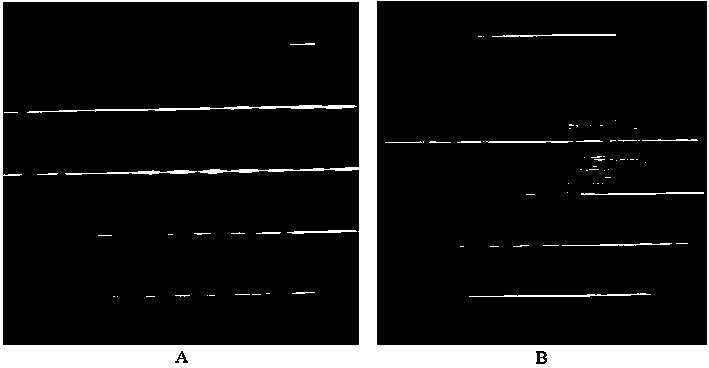

Image

Examples

Embodiment 1

[0024] Cut the bamboo into slices with a thickness of 1 mm, put the bamboo slices in a sodium hydroxide solution with a mass concentration of 0.3%, heat to 100°C for 120 minutes, take them out, wash them with clean water, and soak them in absolute ethanol for 8 hours , during which the absolute ethanol was replaced once, and finally the bamboo slices were soaked in pure tung oil for 3 days, taken out, dripped off the excess tung oil on the surface, and dried in the shade to obtain yellow-brown light-transmitting bamboo slices.

Embodiment 2

[0026] Cut the bamboo into slices with a thickness of 0.1 mm, place the bamboo slices in a sodium metabisulfite solution with a mass concentration of 0.5%, heat to 60°C for 60 minutes, take them out, wash them with water, and soak them in absolute ethanol for 4 hours. During this period, the absolute ethanol was replaced once, and finally the bamboo slices were immersed in pure tung oil for 1 day, taken out, and the excess tung oil on the surface was dripped off and dried in the shade to obtain reddish-brown light-transmitting bamboo slices.

Embodiment 3

[0028] Cut the bamboo into bamboo slices with a thickness of 2 mm, place the bamboo slices in a solution of sodium hydroxide + sodium sulfide with a mass concentration of 1% (the mass ratio of the two is 3.5:1), heat it to 100°C for 90 minutes, take it out and use it Rinse with clean water, then soak in absolute ethanol for 24 hours, replace the absolute ethanol twice during the period, and finally soak the bamboo slices in pure tung oil for 3 days, take it out, drip off the excess tung oil on the surface, and dry in the shade to obtain a reddish-brown translucent Bamboo slices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com