Microwave treatment reconstructed material and preparing methods thereof

A technology of microwave treatment and recombined wood, which is applied in the direction of radiation/wave wood treatment, wood treatment, wood treatment details, etc., can solve the problems of poor resin distribution, high pressurization pressure, and long impregnation time, etc., to achieve uniform density and reduce Low processing cost and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

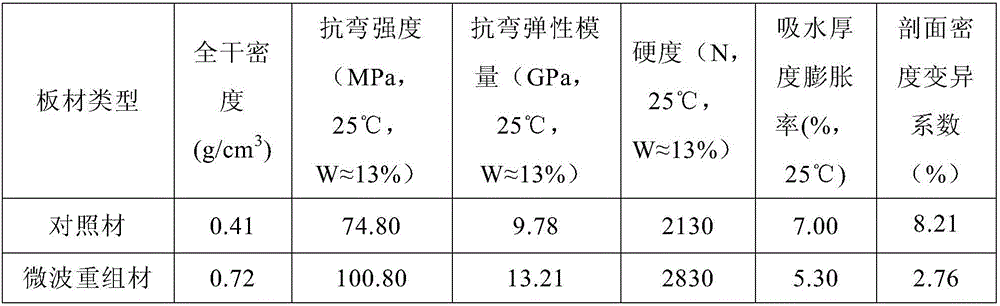

Embodiment 1

[0037] In this embodiment, the microwave-treated recombined material is prepared by using 500 mm (length) × 100 mm (width) × 30 mm (thick) sylvestris sylvestris string cutting board, and the specific steps are as follows:

[0038] (1) by natural drying (air-drying shed of Chinese Academy of Forestry Sciences) or kiln drying (drying temperature 60-80 ℃), the moisture content of Pinus sylvestris lumber is controlled at 30-40%;

[0039] (2) Use continuous tunnel microwave processing equipment (Nanjing Sanle Microwave Technology Development Co., Ltd., model WX100L, the same below) to treat wood with microwaves. The length of the tunnel resonant cavity is 1m, and the cross-sectional size of the tunnel resonant cavity is 0.3m. ×0.25m, the processing parameters are: microwave frequency 915MHz, microwave source power 100kW, microwave volume power 1333kW / m 3 , the processing time is 120s;

[0040] (3) Place the wood (10-25% water content after treatment) and low-molecular-weight urea-...

Embodiment 2

[0045] In this embodiment, the microwave-processed recombined material is prepared by using a 480 mm (length) × 90 mm (width) × 30 mm (thick) sylvestris sylvestris sylvestris string cutting board with a size of 480 mm (length) × 90 mm (width) × 30 mm (thickness).

[0046] (1) by natural drying (air-drying shed of Chinese Academy of Forestry Sciences) or kiln drying (drying temperature 60-80 ℃), the moisture content of Pinus sylvestris lumber is controlled at 30-40%;

[0047] (2) Continuous tunnel microwave treatment equipment is used to treat wood with microwaves. The length of the tunnel resonant cavity is 1m, the cross-sectional size of the tunnel resonant cavity is 0.3m×0.25m, and the processing parameters are: microwave frequency 915MHz, microwave source power 300kW, Microwave volumetric power is 4000kW / m 3 , the processing time is 120s;

[0048] (3) Place the wood treated by microwave in step (2) (the moisture content after treatment is 10-25%) and the soybean adhesive i...

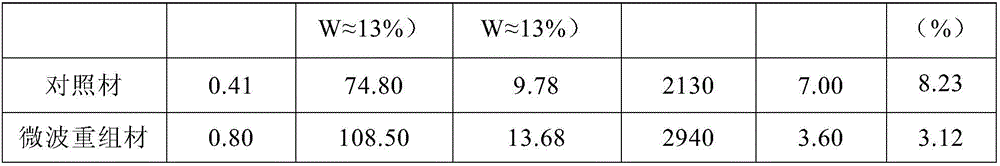

Embodiment 3

[0054] In this embodiment, the microwave-treated recombined wood is prepared by using fir string-cut plates with a size of 500mm (length) × 80mm (width) × 25mm (thickness), and the specific steps are as follows:

[0055] (1) by natural drying (air-drying shed of Chinese Academy of Forestry Sciences), the moisture content of Chinese fir and pine wood is controlled at 30%;

[0056] (2) Continuous tunnel microwave treatment equipment is used to treat wood with microwaves. The length of the tunnel resonant cavity is 1m, the cross-sectional size of the tunnel resonant cavity is 0.3m×0.25m, and the processing parameters are: microwave frequency 915MHz, power 100kW, microwave volume The power is 1333kW / m 3 , the processing time is 120s;

[0057] (3) heat-press the wood processed by microwave in step (2) on a hot-pressing machine, the hot-pressing pressure is 25-50MPa, the hot-pressing temperature is 160-300°C, the hot-pressing time is 15min, and the compression ratio is 50%. Natura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com