Compound beverage made from cordyceps militaris, corn and peanuts

A technology for Cordyceps militaris and peanuts, which is applied to milk replacers, dairy products, applications, etc., can solve problems such as slow growth of benefits, and achieve the effects of improving the degree of softening, good flavor, and reducing soaking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] A kind of cordyceps militaris corn peanut compound beverage, its steps are as follows:

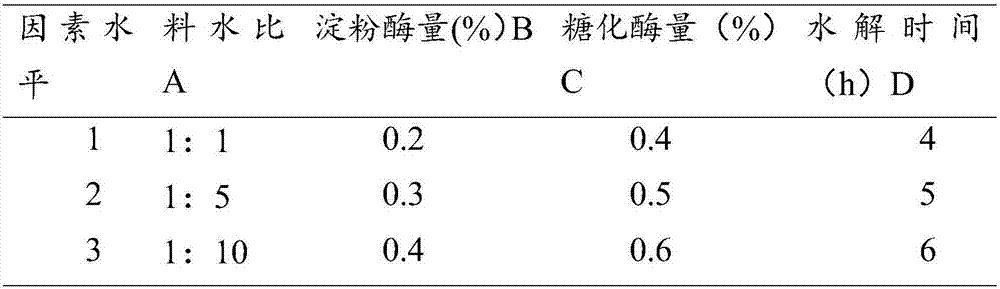

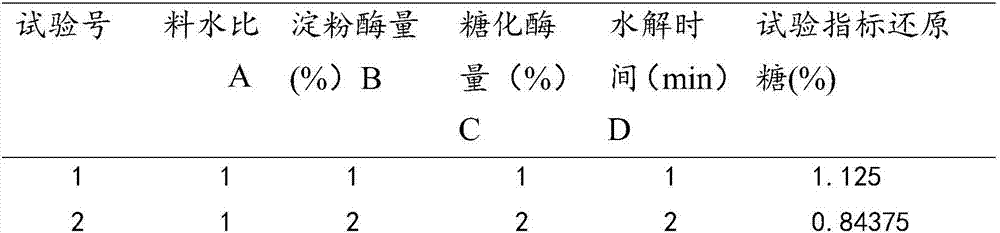

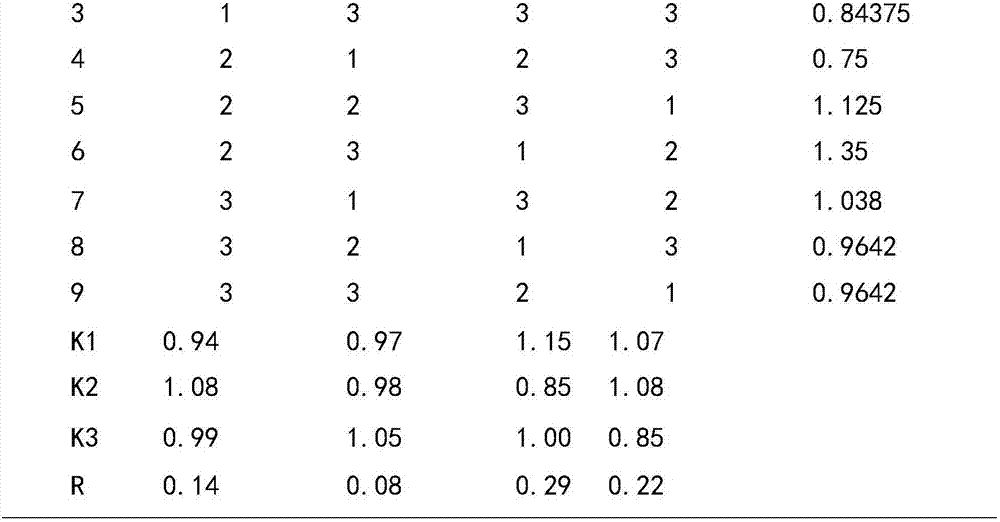

[0108] A, the preparation of hydrolyzate of Cordyceps militaris residue: get the culture medium of 20 parts by weight to obtain the hydrolyzate of Cordyceps militaris residue after gelatinization, liquefaction and saccharification;

[0109] B, pre-treatment of corn: take 70 parts by weight of corn and put it into the temperature of 160 ℃ and bake for 20 minutes, then take it out and add 30 parts by weight of unroasted corn, and add four times of water and 0.2% of the total mass of corn Lactic acid, soaked at 50°C for 8 hours;

[0110] C. Pre-treatment of peanuts: take 30 parts by weight of peanuts and put them into the oven for 20 minutes at a temperature of 120° C., then add three times the amount of water and 0.1% of the total mass of peanuts, and soak them for 9 hours at 40° C.;

[0111] D. Refining: heat the materials obtained in step B and step C to 100°C, and keep it for 10 m...

Embodiment 2

[0126] Its difference with embodiment one is: a kind of cordyceps militaris corn peanut compound beverage, its steps are as follows:

[0127] A, the preparation of hydrolyzate of Cordyceps militaris residue: get the culture medium of 20 parts by weight to obtain the hydrolyzate of Cordyceps militaris residue after gelatinization, liquefaction and saccharification;

[0128] B, pre-treatment of corn: take 70 parts by weight of corn and put it into the temperature of 140 ℃ and bake for 15 minutes, then take it out and add 25 parts by weight of unroasted corn, and add four times of water and 0.1% of the total mass of corn Lactic acid, soaked at 40°C for 6h;

[0129] C. Pre-treatment of peanuts: get 30 parts by weight of peanuts and bake them at a temperature of 110° C. for 15 minutes, then add three times of water and 0.08% of the total mass of peanuts with baking soda, and soak at 35° C. for 8 hours;

[0130] D. Refining: heat the materials obtained in step B and step C to 95°C ...

Embodiment 3

[0136] Its difference with embodiment one is: a kind of cordyceps militaris corn peanut compound beverage, its steps are as follows:

[0137] A, the preparation of hydrolyzate of Cordyceps militaris residue: get the culture medium of 20 parts by weight to obtain the hydrolyzate of Cordyceps militaris residue after gelatinization, liquefaction and saccharification;

[0138] B. Pre-treatment of corn: take 70 parts by weight of corn and bake at 180°C for 30 minutes, then take it out and add 35 parts by weight of unroasted corn, and add four times the water and 0.3% of the total mass of corn Lactic acid, soaked at 60°C for 10h;

[0139] C. Pre-treatment of peanuts: get 30 parts by weight of peanuts and put them into the oven for 30 minutes at a temperature of 130° C., then add three times the amount of water and 0.15% of the total mass of peanuts, and soak them for 12 hours at 45° C.;

[0140] D. Refining: Heat the materials obtained in step B and step C to 110°C respectively, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com