A kind of persimmon cake processing method

A processing method and technology of persimmons, which are applied in the fields of protecting fruits/vegetables with a coating protective layer, food science, and preservation of fruits and vegetables. It can solve the problems of difficulty in realizing industrialized mass production, easy adhesion of dust on the surface of persimmons, and prolonging the processing time of persimmons. , to achieve clean production, reduce mildew and rot, and avoid mold pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

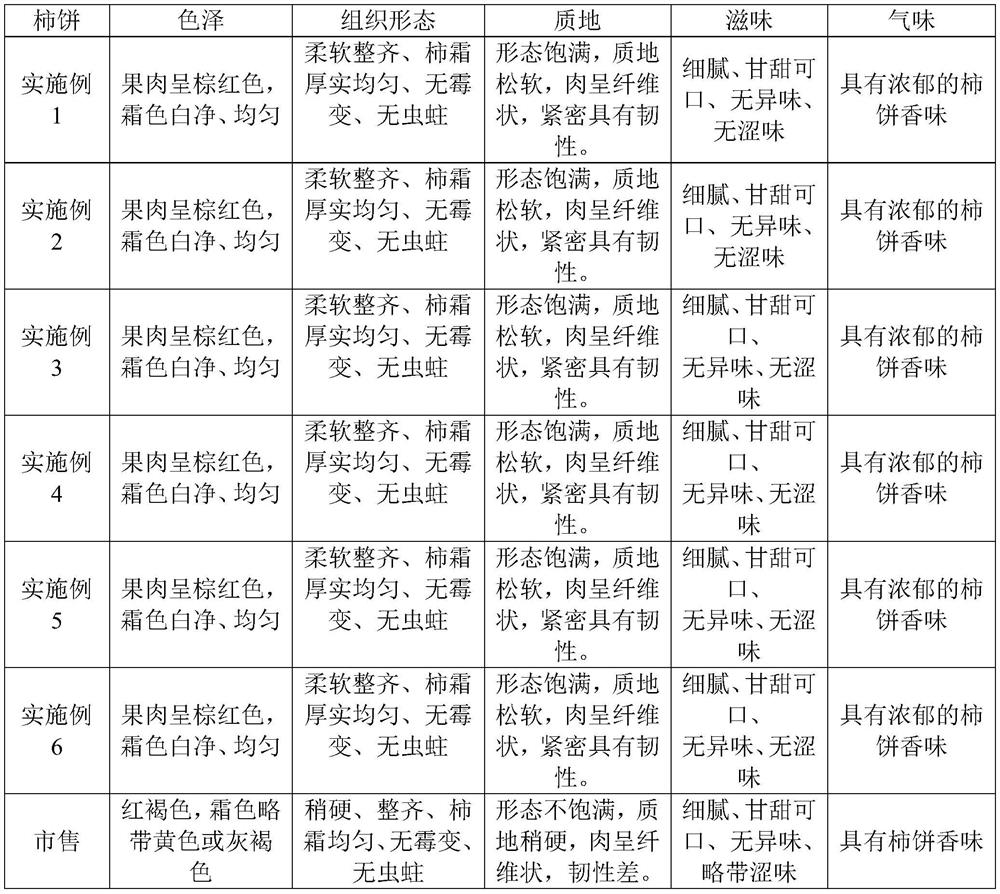

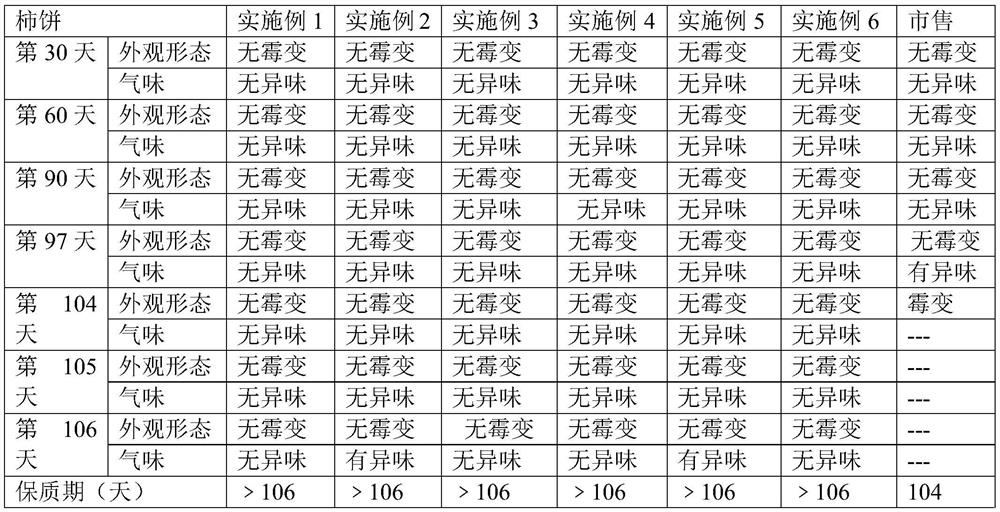

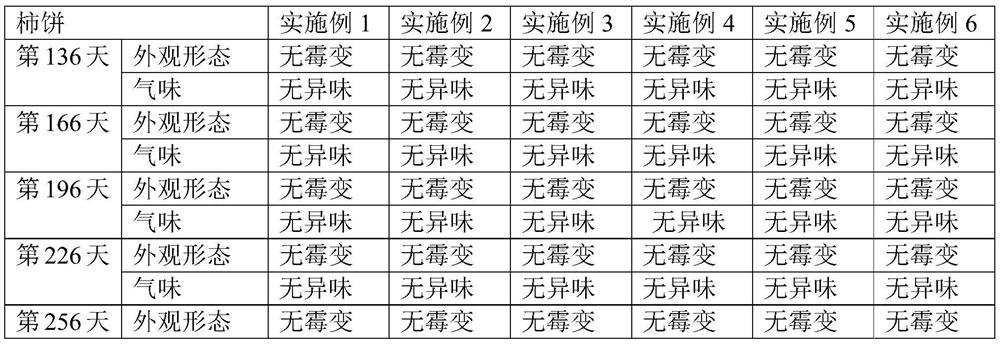

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

[0029] S1, fruit selection: select persimmons with complete fruit bodies, no pests and diseases, and ripe yellowish reddish skin, and ventilate and dry at room temperature for 12 hours;

[0030] S2. Peeling: Peel the dried persimmons in step S1, then soak them in a 2% konjac glucomannan solution for 3 minutes, and then take them out to dry;

[0031] S3, deastringency: Knead the dried persimmons in step S2 until the surface of the persimmons is complete, the inner pulp is soft and free of hard lumps and joint tissues, and then deastringent treatment is performed; the specific process of deastringency treatment is as follows: : the kneaded persimmons were treated at a temperature of 85° C. for 4 minutes and cooled to room temperature, and then treated at a temperature of 70° C. for 8 minutes and cooled to room temperature;

[0032] S4. Primary ripening: bake the deastringent persimmons in step S3 at a temperature of 55°C fo...

Embodiment 2

[0036] This embodiment includes the following steps:

[0037] S1, fruit selection: select persimmons with complete fruit bodies, no pests and diseases, and ripe yellowish reddish skin, and ventilate and dry at room temperature for 15 hours;

[0038] S2. Peeling: Peel the dried persimmons in step S1, then soak them in a konjac glucomannan solution with a mass content of 1.8% for 3 minutes, and then take them out to dry;

[0039]S3, deastringency: Knead the dried persimmons in step S2 until the surface of the persimmons is complete, the inner pulp is soft and free of hard lumps and joint tissues, and then deastringent treatment is performed; the specific process of deastringency treatment is as follows: : the kneaded persimmons were treated at a temperature of 88° C. for 3 minutes and cooled to room temperature, and then treated at a temperature of 75° C. for 6 minutes and cooled to room temperature;

[0040] S4. Primary ripening: bake the deastringent persimmons in step S3 at ...

Embodiment 3

[0044] This embodiment includes the following steps:

[0045] S1, fruit selection: select persimmons with complete fruit bodies, no pests and diseases, and ripe yellowish reddish skin, and ventilate and dry at room temperature for 18 hours;

[0046] S2. Peeling: Peel the dried persimmons in step S1, then soak them in a 2% konjac glucomannan solution for 2 minutes, and then take them out to dry;

[0047] S3, deastringency: Knead the dried persimmons in step S2 until the surface of the persimmons is complete, the inner pulp is soft and free of hard lumps and joint tissues, and then deastringent treatment is performed; the specific process of deastringency treatment is as follows: : processing the kneaded persimmons at a temperature of 90° C. for 3 minutes and cooling to room temperature, then treating the kneaded persimmons at a temperature of 75° C. for 10 minutes and cooling to room temperature;

[0048] S4. Primary ripening: bake the deastringent persimmons in step S3 at a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com