Food processor

A technology for food processing machines and hosts, applied in kitchen utensils, home utensils, applications, etc., can solve problems such as inconvenience and heavy glass cups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

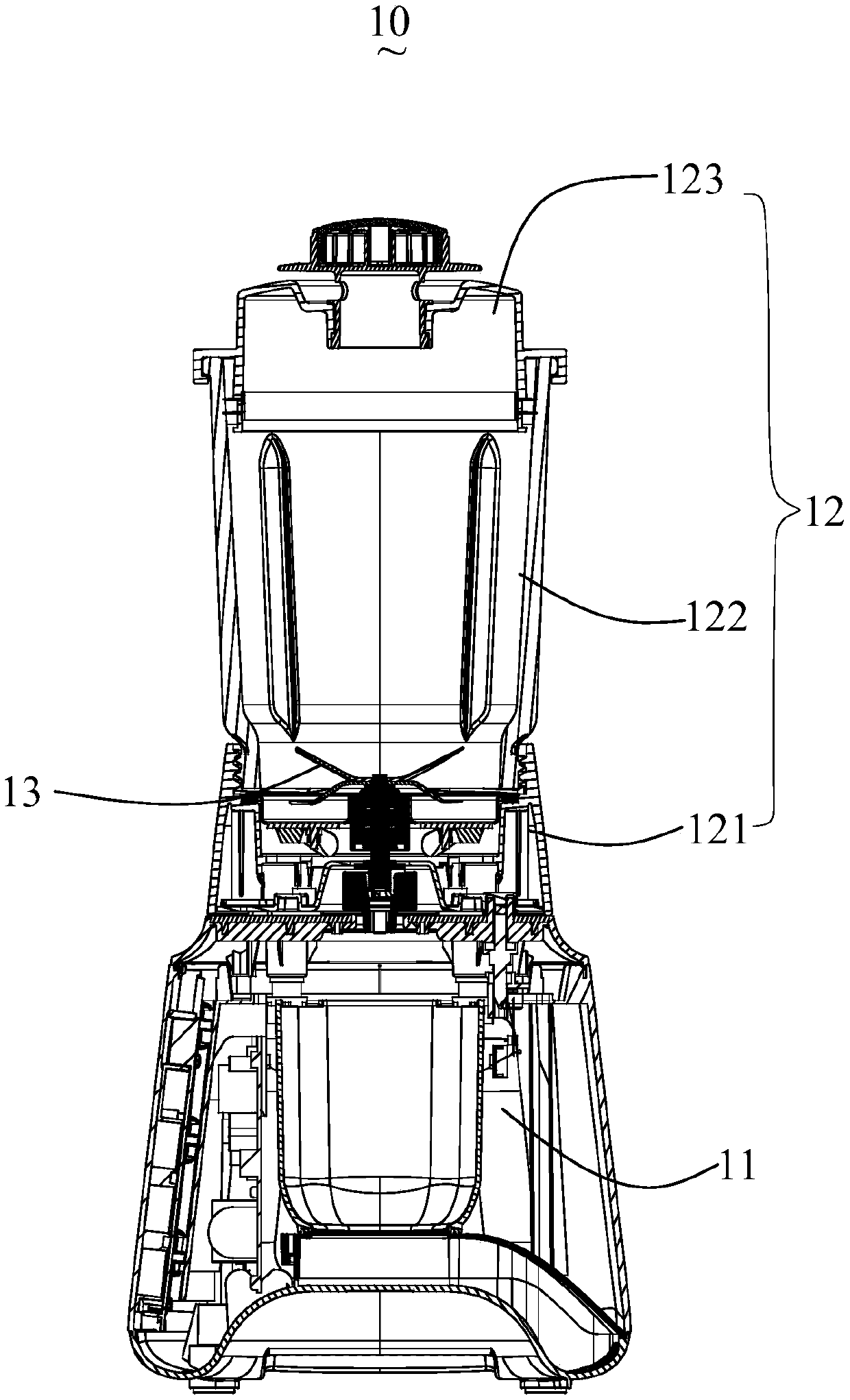

[0032] see figure 1 The schematic diagram of the first preferred embodiment of the food processor, the food processor 10 includes a main machine 11, a motor arranged in the main machine 11, a stirring cup 12 arranged above the main machine, and a crushing machine arranged in the stirring cup 12 Knife 13, the crushing knife 13 is connected to the motor shaft of the motor through a connector, the stirring cup 12 includes a cup base 121, a glass body 122 and a cup cover 123, and the cup cover 123 is covered on the glass At the upper opening of the cup body 122 , the cup holder 121 is installed at the lower opening of the glass cup body 122 .

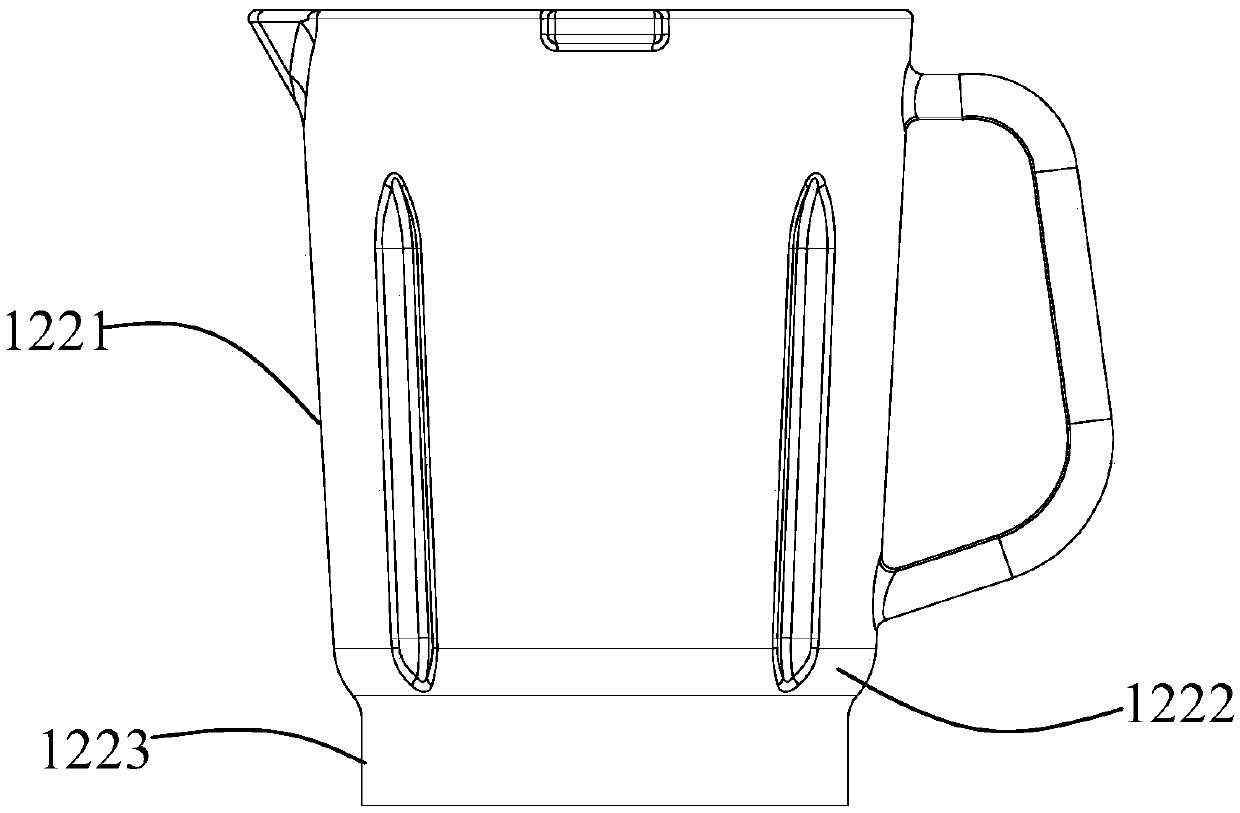

[0033] Please also refer to figure 2 , in this embodiment, the glass cup body 122 sequentially includes an anti-overflow section 1221 , a heat gathering section 1222 , and an installation section 1223 from top to bottom. The anti-overflow return section 1221 gradually becomes thinner from the bottom to the top. In this way, since the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com