Curved bamboo material original state regroup method and its making method

A manufacturing method and arc-shaped technology, applied in the field of materials, can solve the problems of destroying the macroscopic structure of natural bamboo, irreplaceable, and affecting the quality of the section, so as to save forest resources and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

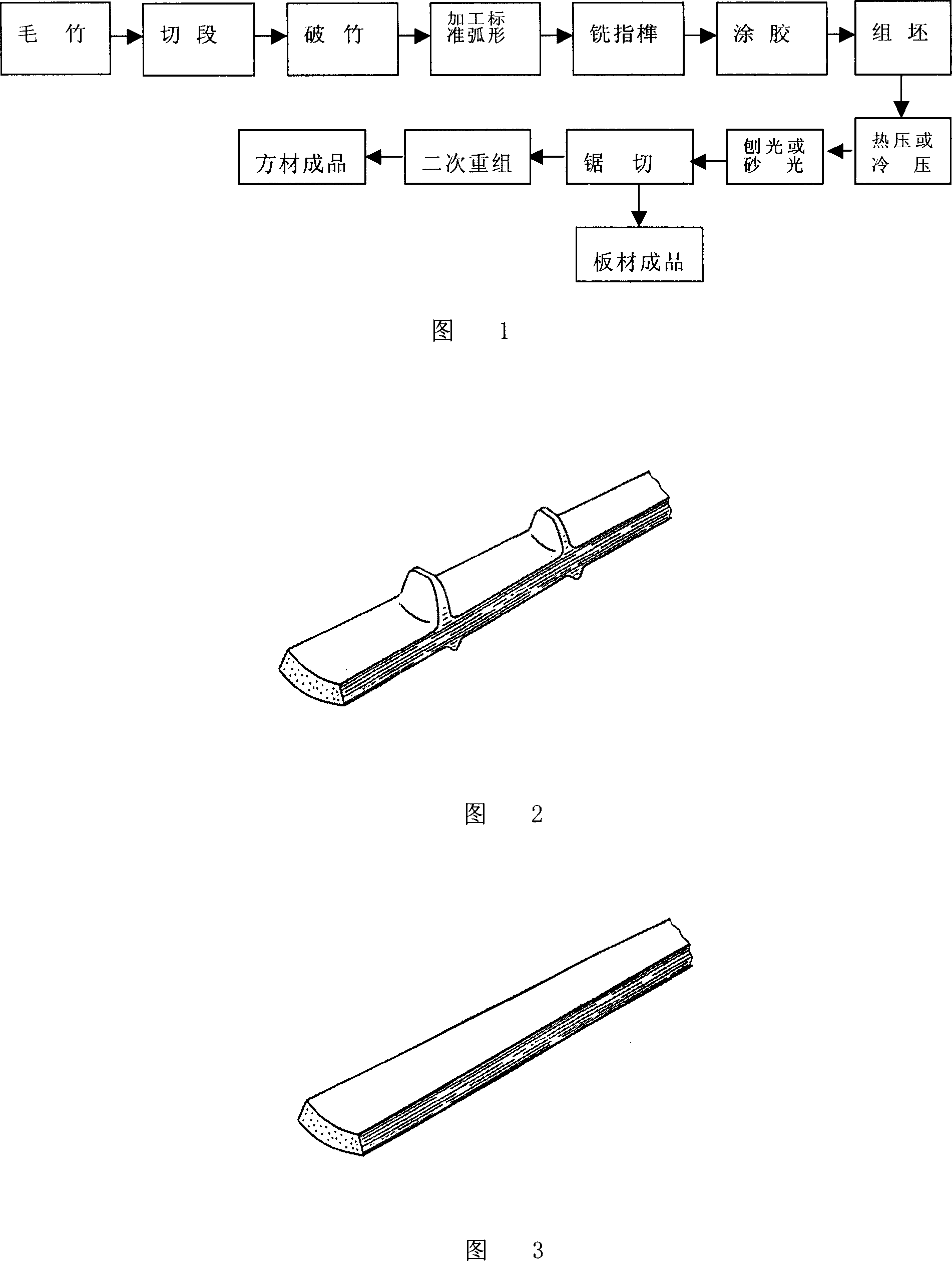

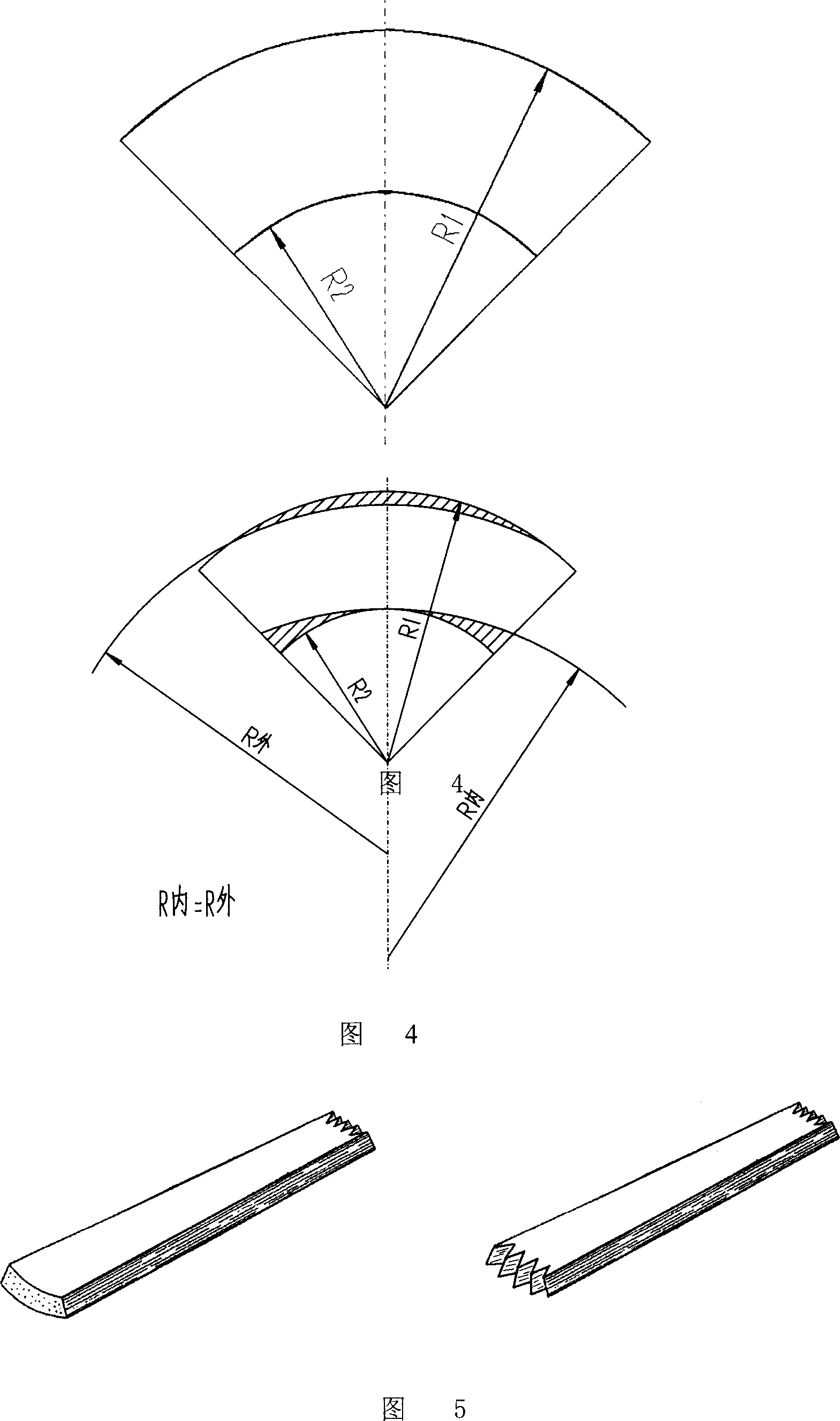

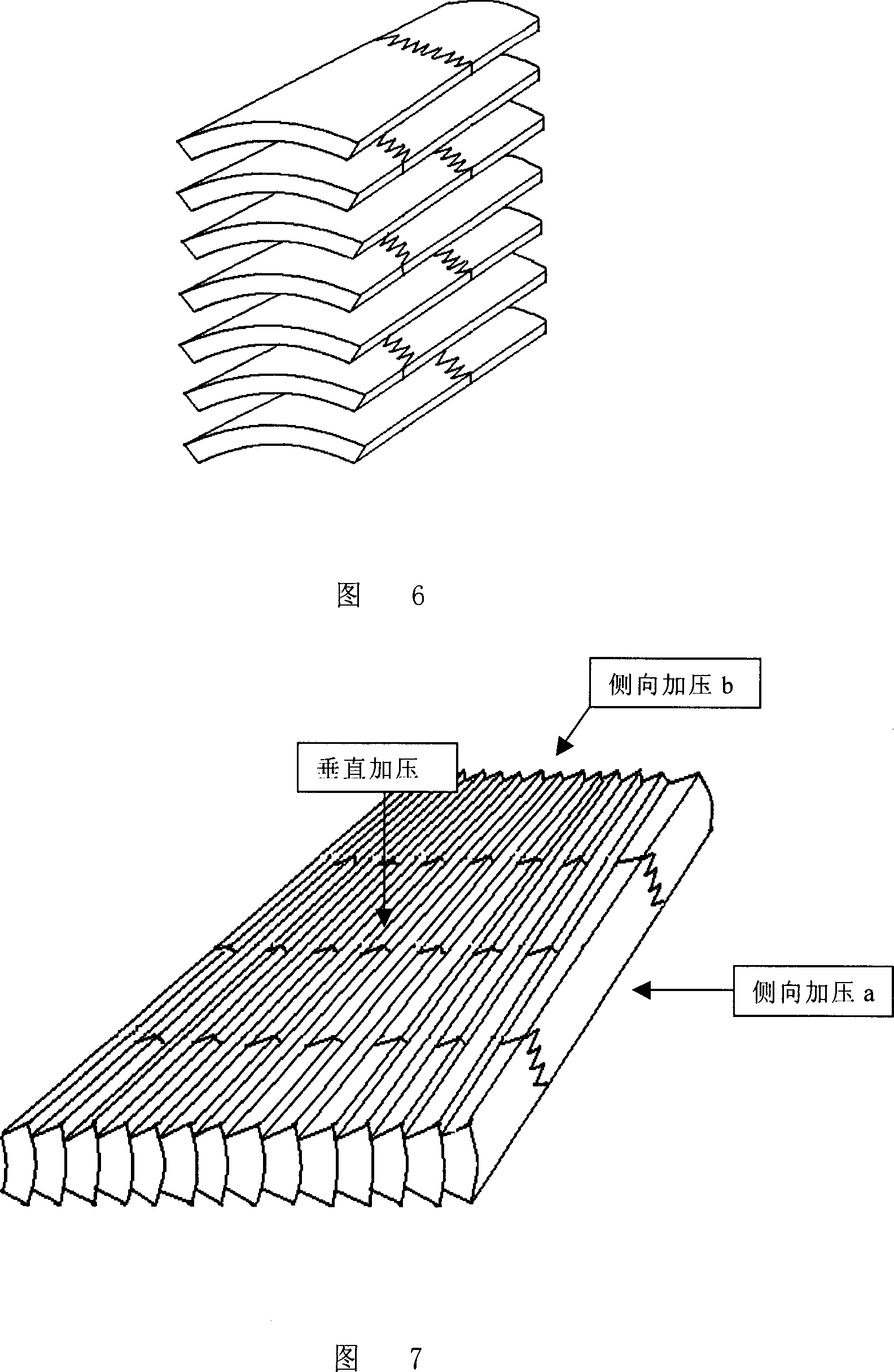

[0036] Referring to Figures 1-9, according to the different diameters of the bamboo, the bamboo is split into curved bamboo blanks of a certain specification, and the inner and outer bamboo joints are removed by milling, and the "standard curved" bamboo blanks with the same specifications and smooth surface are processed. , one end or double short milling finger tenon. Then arc-shaped anastomosis is superimposed and glued to form a board, or a second reorganization is made to form a square material. Specific steps are as follows:

[0037] (1) Cut the moso bamboo into standard sections with a length of 500-3000 mm according to the diameter, taper, wall thickness and straightness of the bamboo. The bamboo splitting machine is used to split the round bamboo into arc-shaped blanks.

[0038] Specifications: Length: 500~3000mm

[0039] Width: 20~60mm

[0040] Thickness: natural wall thickness of bamboo

[0041] (2) Milling the bamboo green surface and the bamboo yellow surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com