Flattened bamboo plate material and making method thereof

A manufacturing method, bamboo board technology, applied in the direction of manufacturing tools, chemical instruments and methods, wood compression, etc., can solve the problems of surface cracking, increased manufacturing cost, low utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention provides a flattened bamboo board composed of a single-layer bamboo board, and the bamboo board includes bamboo green, bamboo meat and bamboo yellow parts. In one embodiment of the present invention, a flattened bamboo board is formed by splitting a bamboo tube longitudinally into one or several flattened pieces.

[0025] In the methods disclosed herein, adhesives may not be used. In one embodiment of the present invention, no adhesive is used for the flattened bamboo boards. In another embodiment of the present invention, the flattened bamboo board is a board with increased density compared to the bamboo tube.

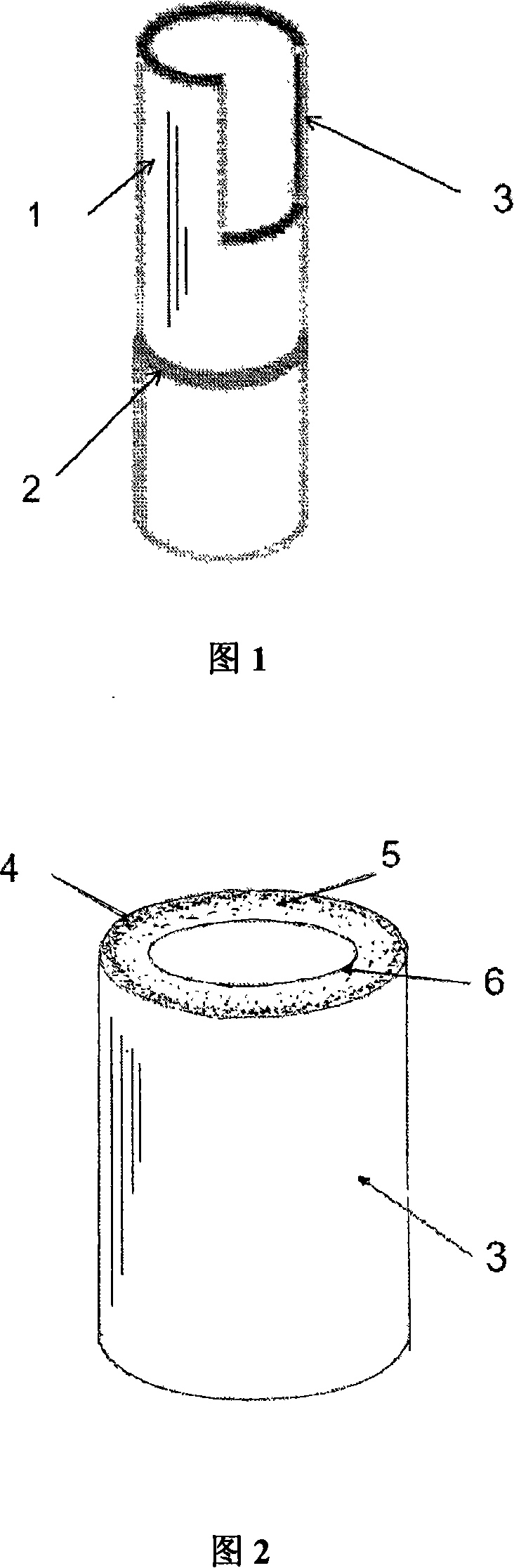

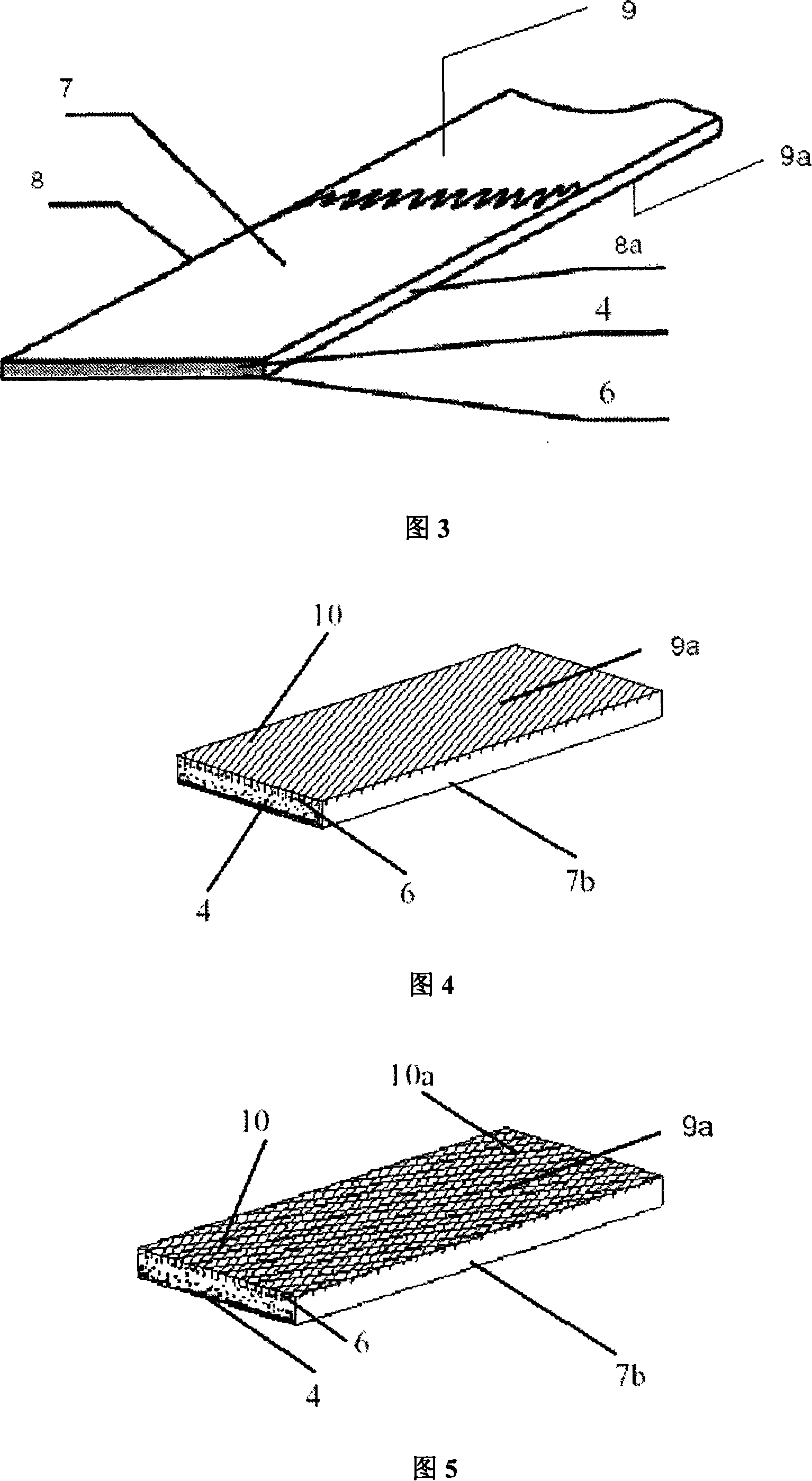

[0026] Referring to the accompanying drawings, Fig. 1 is a schematic diagram of the bamboo tube part, wherein the bamboo tube 1 is made up of bamboo joints 2 and bamboo walls 3 . Fig. 2 is the enlarged cross-sectional schematic view of bamboo wall 3, wherein the density of bamboo wall 3 changes gradually from bamboo green to bamboo yellow part, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com