Step for flattening arc-shaped bamboo remaining bamboo outer and inner surface layer, flattening method using the same step and flattening device

An arc-shaped, bamboo technology, applied in the direction of wood compression, can solve the problems of destroying the characteristics of bamboo, reducing the strength of bamboo, easy to crack, etc., to achieve the effect of ensuring strength and toughness, and retaining high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

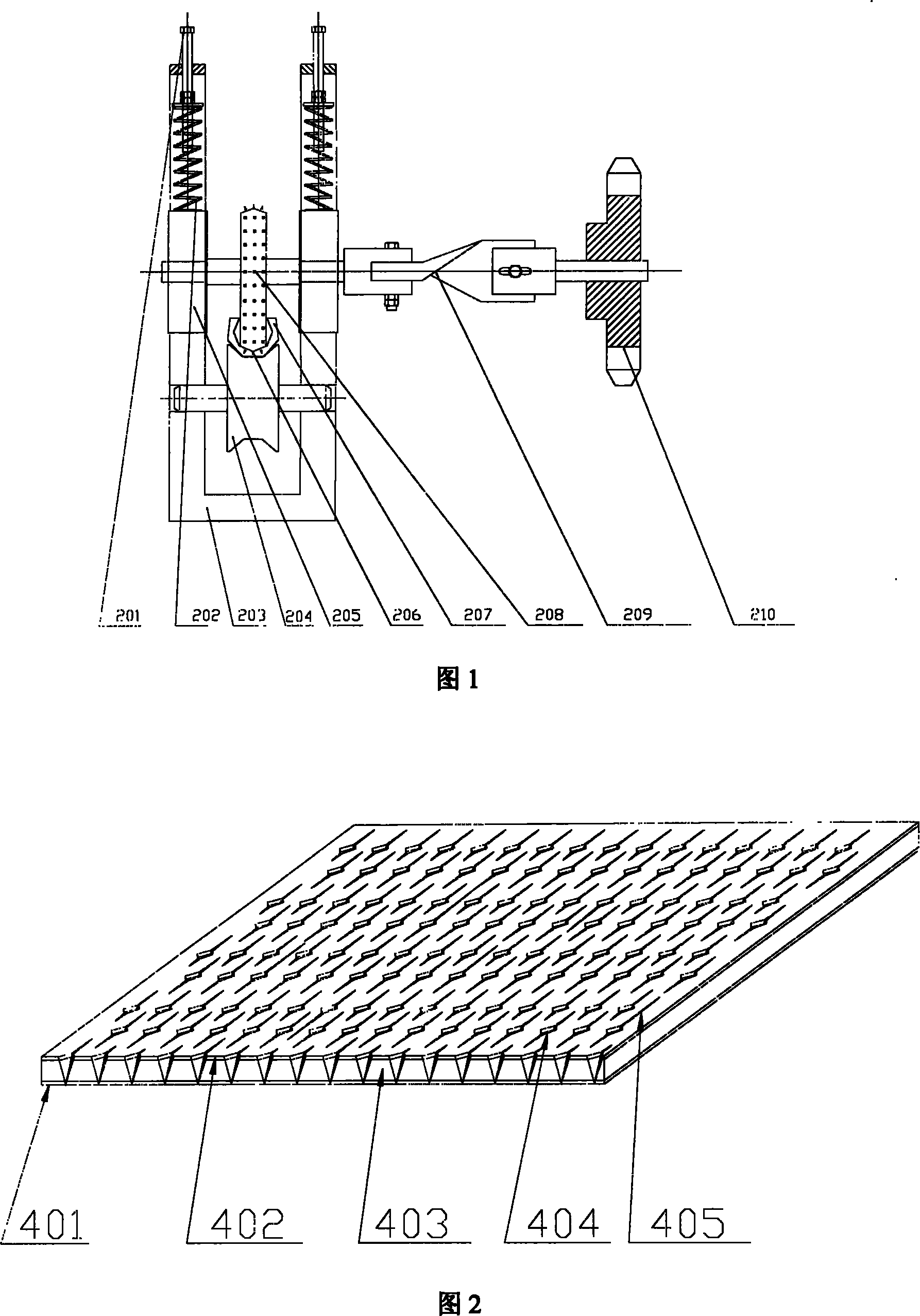

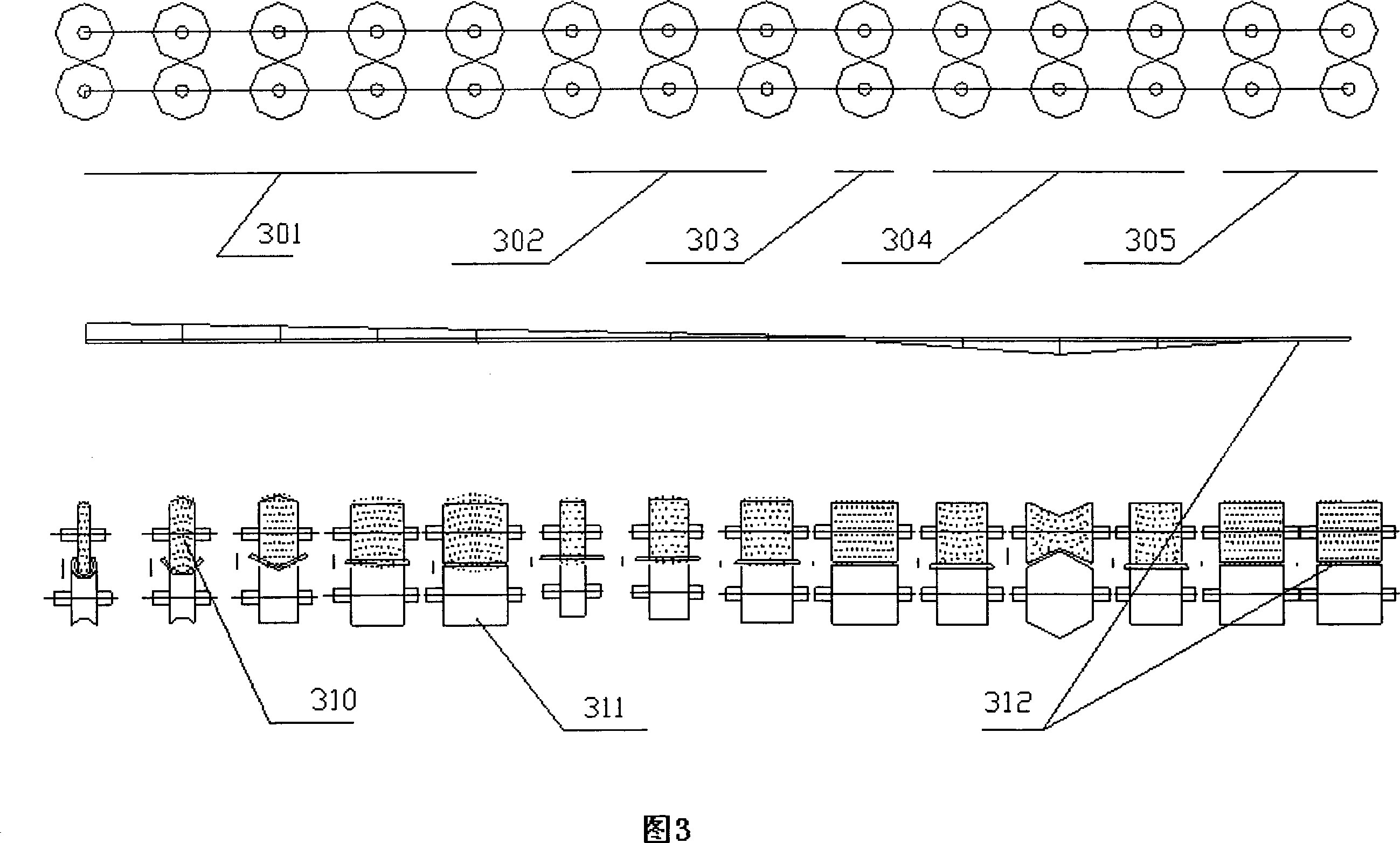

[0024] Below in conjunction with Fig. 1, Fig. 2 and Fig. 3, the present invention is described in detail, selects the bamboo of more than 3 years of raw bamboo diameter in 30-60MM and the small diameter miscellaneous bamboo and industrial waste bamboo such as early bamboo, thunder bamboo as raw material. Fresh bamboo can be used for 3-12 months. The width of the pressing machine is cut into 2500MM bamboo segments, and the bamboo segments are notched, then softened by microwave, and then flattened. Under the combined action of the block 205 and the Oldham coupling 209, the raised steel nails 206 on the upper roller are inserted into the arc-shaped original bamboo 207, and the power is transmitted to the Oldham coupling 209 and the upper roller 208 through the sprocket 210 to drive the upper roller. 208 scroll. During rolling, the arc-shaped original bamboo 207 is pressed with a large number of artificially induced cracking holes by steel nails 206. The shape of the steel nails...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com