Preparation method of precipitated silicon dioxide for high-resilience transparent silicon rubber

A technology of precipitated silica and resilience, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problem of poor resilience and transparency of silicone rubber, high production cost of fumed silica, and structural control In order to achieve the effects of good resilience, simple and environmentally friendly preparation process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

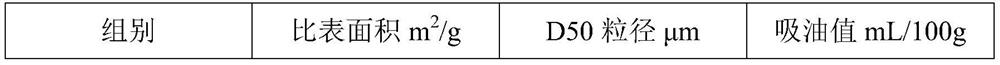

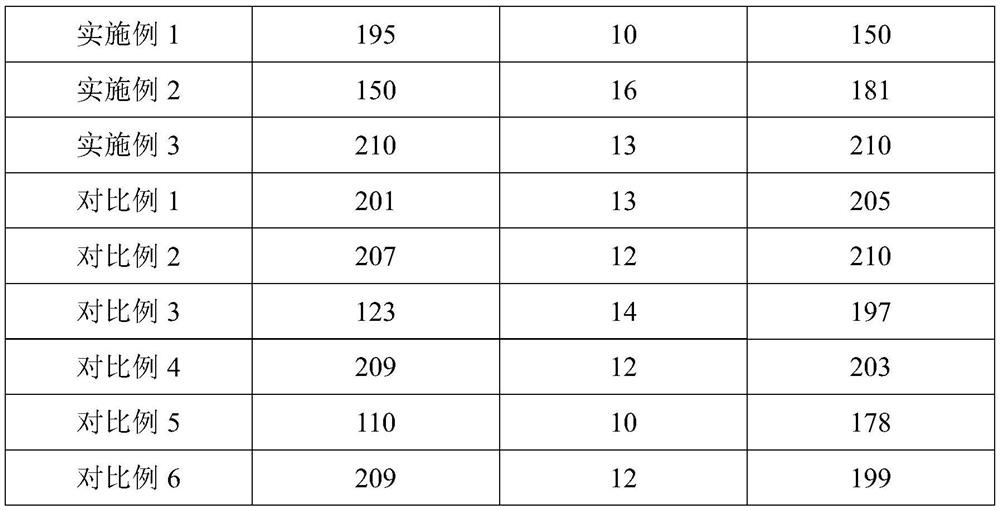

[0032] Example 1, a preparation method of precipitated silica for high resilience silicone rubber

[0033] A preparation method of precipitated silica for high resilience silicone rubber, comprising the following steps:

[0034] S1. After liquefying solid sodium silicate with a modulus of 1.5 at high temperature, add water to form a sodium silicate solution with a concentration of 2.0mol / L;

[0035] S2, configuration concentration is the sulfuric acid solution of 2.0mol / L;

[0036] S3, add 8m to the reactor 3 into tap water, then add 5m 3 The sodium silicate solution prepared in step S1 is heated to 80°C, the stirring device is turned on and the stirring frequency is set to 25Hz, and the sulfuric acid solution prepared in step S2 is added dropwise while stirring, and the dropping speed of the sulfuric acid solution is 3m 3 / h, the control reaction terminal pH value is 8.0;

[0037] S4, continue to drip the sodium silicate solution that step S1 makes and the sulfuric acid s...

Embodiment 2

[0039] Example 2, a preparation method of precipitated silica for high resilience silicone rubber

[0040] A preparation method of precipitated silica for high resilience silicone rubber, comprising the following steps:

[0041] S1. After liquefying solid sodium silicate with a modulus of 3.5 at high temperature, add water to form a sodium silicate solution with a concentration of 3.0mol / L;

[0042] S2, configuration concentration is the sulfuric acid solution of 4.8mol / L;

[0043] S3, add 12m to the reactor 3 into tap water, then add 7.5m 3 The sodium silicate solution prepared in step S1 is heated to 95°C, the stirring device is turned on and the stirring frequency is set to 30Hz, and the sulfuric acid solution prepared in step S2 is added dropwise while stirring, and the dropping speed of the sulfuric acid solution is 8m 3 / h, the control reaction terminal pH value is 10.5;

[0044] S4, continue to drip the sodium silicate solution that step S1 makes and the sulfuric ac...

Embodiment 3

[0046] Example 3, a preparation method of precipitated silica for high resilience silicone rubber

[0047] A preparation method of precipitated silica for high resilience silicone rubber, comprising the following steps:

[0048] S1. After liquefying solid sodium silicate with a modulus of 2.5 at high temperature, add water to form a sodium silicate solution with a concentration of 2.5mol / L;

[0049] S2, configuration concentration is the sulfuric acid solution of 3.2mol / L;

[0050] S3, add 10m to the reactor 3 into tap water, then add 6.1m 3 The sodium silicate solution prepared in step S1 is heated to 87°C, the stirring device is turned on and the stirring frequency is set to 28Hz, and the sulfuric acid solution prepared in step S2 is added dropwise while stirring, and the dropping speed of the sulfuric acid solution is 6m 3 / h, the control reaction terminal pH value is 9.2;

[0051] S4, continue to drip the sodium silicate solution that step S1 makes and the sulfuric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com